9

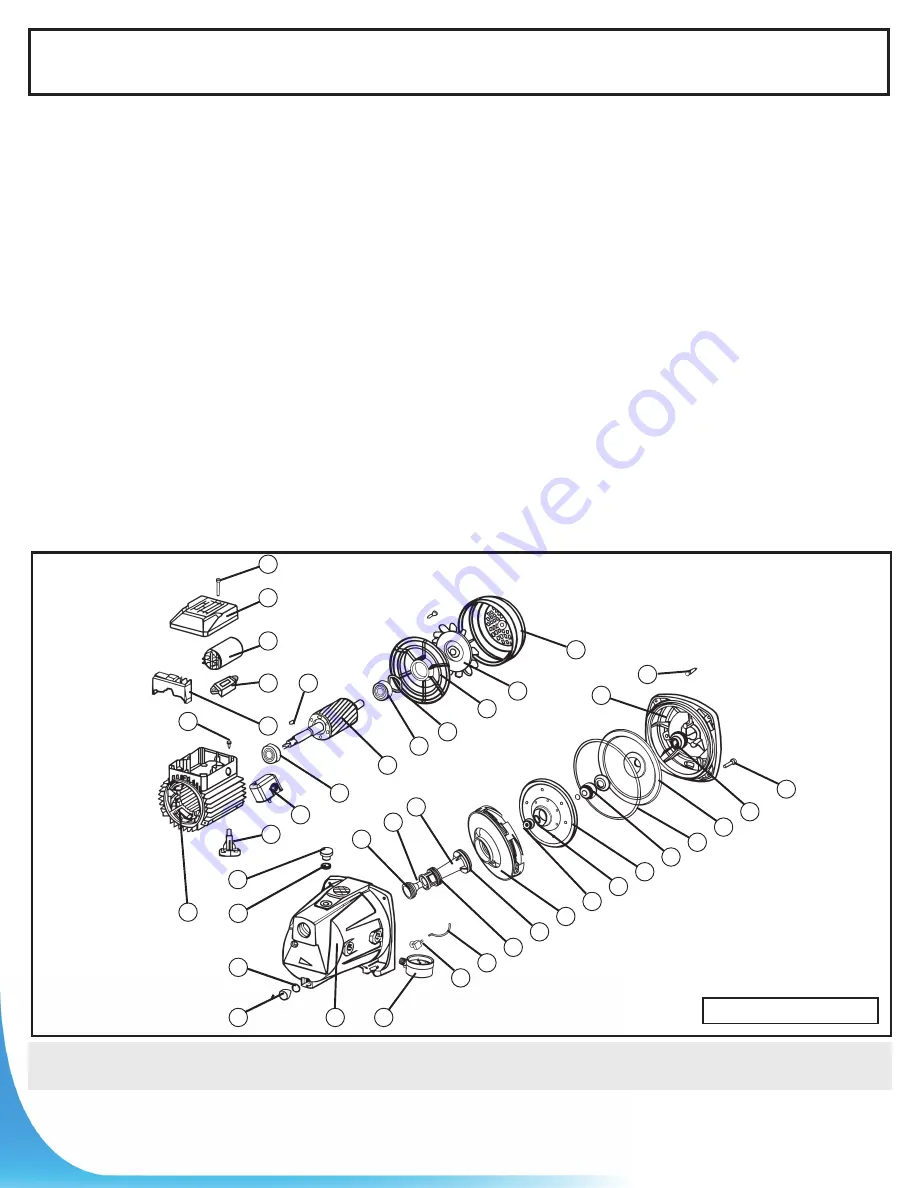

REPAIR PARTS

Repair parts may be ordered from your authorized point of sale or from

BUR-CAM PUMPS

Ref P

art

Description

1

506391

C.I. pump body

2

750769

Pressure gauge

3

52319

1/4”NPT 1/8”barb brass adaptor

4

506052

Nozzle “O” ring

5

750748

Plastic tubing

6

506389

Nozzle

7 506380

Venturi

8 506388

Venturi “O” ring

9

506053S

Venuri “O” ring

10 506085

Diffuser

11 506055

Impeller brass nut

12 506381

Gasket

13 506083

Noryl impeller

14 506057

Mechanical shaft seal

15 350129

Pump body “O” ring

16 506059GP

S.S. seal plate

17 506060

Sand slinger

18 506062

Body cap screw

19 506061GP

Pump bracket

20 506383

Motor flange cap screw

21 506074GP

Fan cover

Ref P

art

Description

22 506073W

Motor fan

23 506072GP

Motor end bell

24 506385

Wave spring washer

25 350335

Motor bearing fan side

26 506070GP

Rotor/shaft

27 506069

Rotor shaft key

28 350335

Motor bearing pump side

29 750957S

Pressure switch

30 506075

Motor/pump foot

31 506300

Priming plug

32 506400

Priming plug washers

33 506315

Washer

34 506299

Draining plug

35 506067GP2V Stator winding

36 506386

Grounding screw

37 506065

Capacitor junction block

38 506094

115/230V selector

39 506064

Motor capacitor

40 506014

Cover box junction

41 506384

Cover box screw

506121SW 2009

40

41

39

37

30

29

38

1

5

3

2

31

32

33

34

35

36

15

14

10

9

6

4

17

7

16

18

8

19

22

23

25

26

27

28

21

20

11

13

12

24

Venturi ‘‘O’’ ring