Form #117 (2.09)

4500 E. 142nd Street • Grandview, MO 64030 • Tel. (816) 878-6675 • Fax (816) 878-6683 • www.smartflow-usa.com

General

F

AS

T

IE

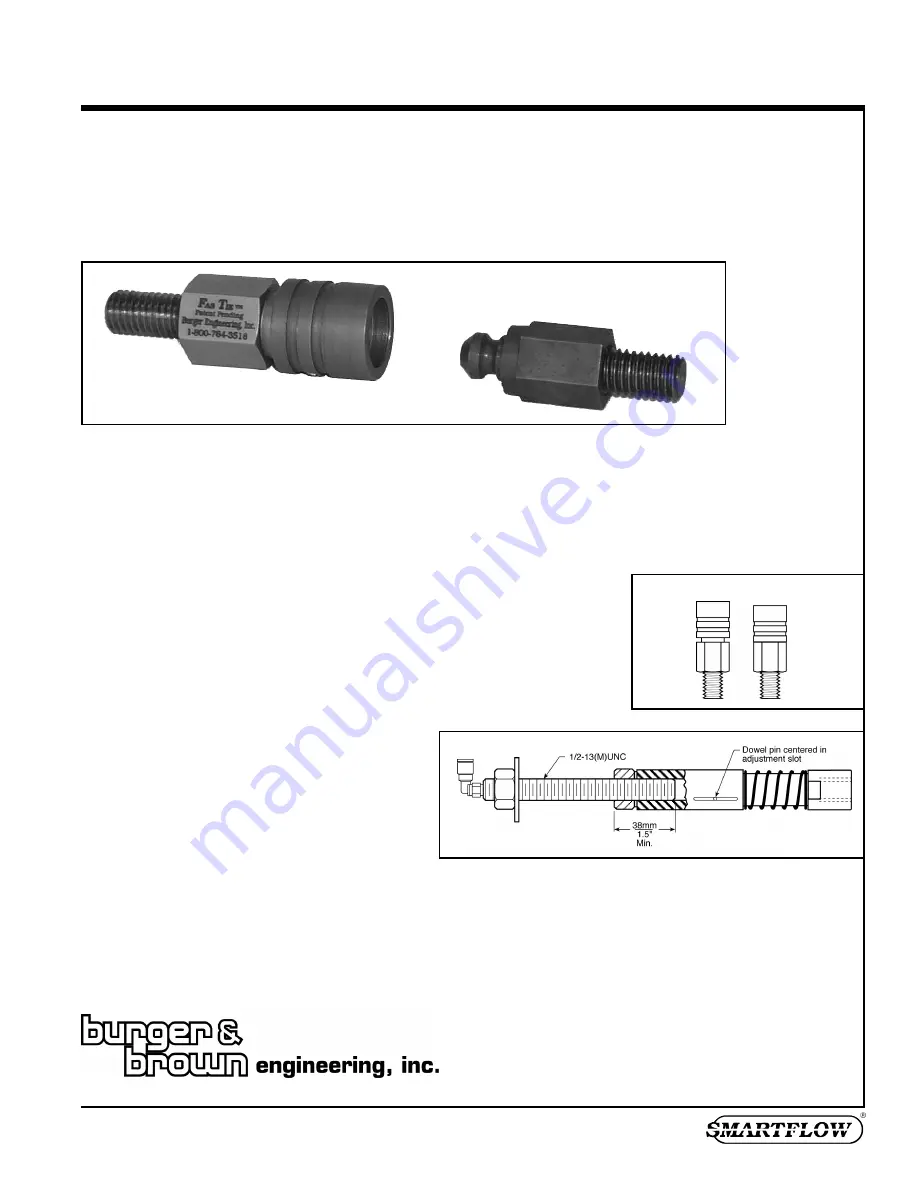

Quick-Connect Knock-Out System “ties-in” the mold ejector plate to the press ejection system. A

pneumatically-operated piston inside the coupler releases the stud from the press ejection system to reduce

set-up and change-out times.

Adjustable or fixed-length

F

AS

T

IE

ejector bars may be used with the couplers and studs. Adjustable ejector

bars allow mold-setters to compensate for variance in molds and presses up to 1/2" in each direction. Fixed-

length ejector bars may be made-to-order for custom installation.

The

F

AS

T

IE

air manifold option distributes shop air to each coupler. The aluminum

manifold supplies air to up to four couplers. Pneumatic fittings and tubing are included.

Caution: Couplers must be in the open position before connecting with

studs. See figure 1. Coupler damage will result from improper set-up.

Do not operate injection molding press with couplers in the open position!

Maintenance

FasTie couplers must be greased to operate smoothly.

Visually inspect coupler each month or each tool change

for the presence of grease. Generously apply grease to

stud end, connect the coupler to the stud, then release

and repeat.

Before Installation

Before clamping a mold to the injection molding machine, machine ejector plate must be completely

retracted to the “home” position.

If using a SpeedBar adjustable knock-out bar, check that at least 1.5" (38mm or 20 complete turns) of the

1/2-13 stud is threaded into the body of the knock-out bar with the dowel pin centered in the adjustment

slot. See figure 2.

SMARTFLOW®

1" FasTie® Quick-Connect Knock-Out System

and SpeedBar® Adjustable Knock-Out Bar

Installation Instructions

figure 2

figure 1

Coupler

Open

Coupler

Closed

S

PEED

B

AR

™

US Patent Numbers:

6,379,072 6,315,544