8

Understandingtheratingplate

Type 8228

5

unDersTAnDinG The rATinG

plATe

8228 Inductive Conductivity Meter V2

Supply: 12-36V

40W max.

Output: 1x 4-20mA 1xTrans 700mA max.

Cell: PEEK Range 100 µS/cm - 2 S/cm

Process: Temp -15 to 130°C

PN 10, limited by fitting material and fluid temp.

IP65-IP67 W41MN

S-N:1000

00566615

1:V+

2:NPN/PNP1

3:0V

4:I1

2

5

6

7

8

9

3

1

10

11

12

13

14

16

15

18

17

4

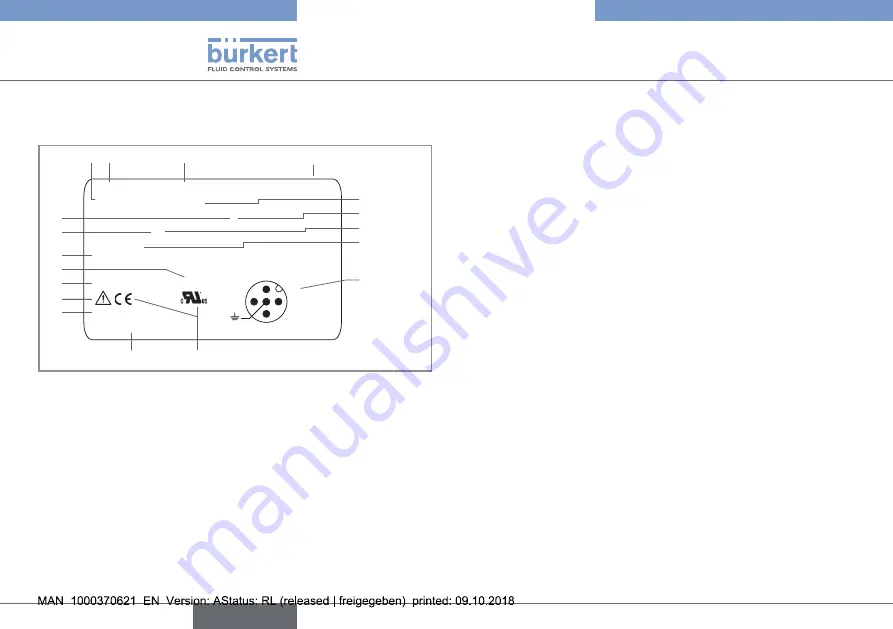

Fig. 1:

Rating plate of the device (example)

1. Supply voltage

2. Type of the device

3. Measurable variable

4. Version

5. Max. power consumption

6. Max. current available at the transistor output(s)

7. Conductivity measuring range

8. Fluid temperature range

9. Pin assignment of the M12 fixed connector(s)

10. Conformity marking

11. Article number

12. Serial number

13. Warning: Before using the device, take into account the tech-

nical specifications described in the Operating Instructions.

14. Protection rating

15. Construction code

16. Nominal pressure of the fluid

17. Material of the conductivity sensor holder

18. Available outputs

English

Summary of Contents for 8228 ELEMENT

Page 32: ...www burkert com ...