12

F.

Move boiler to permanent location

by sliding or

walking. Do not drop.

For Packaged Boiler, proceed to Paragraph L.

G.

Confirm that one (1) Flue Baffle is properly

positioned in each Boiler Flueway.

Tabs at the top

of each Flue Baffle should be resting on top row of Flue

Pins on each adjoining section.

H.

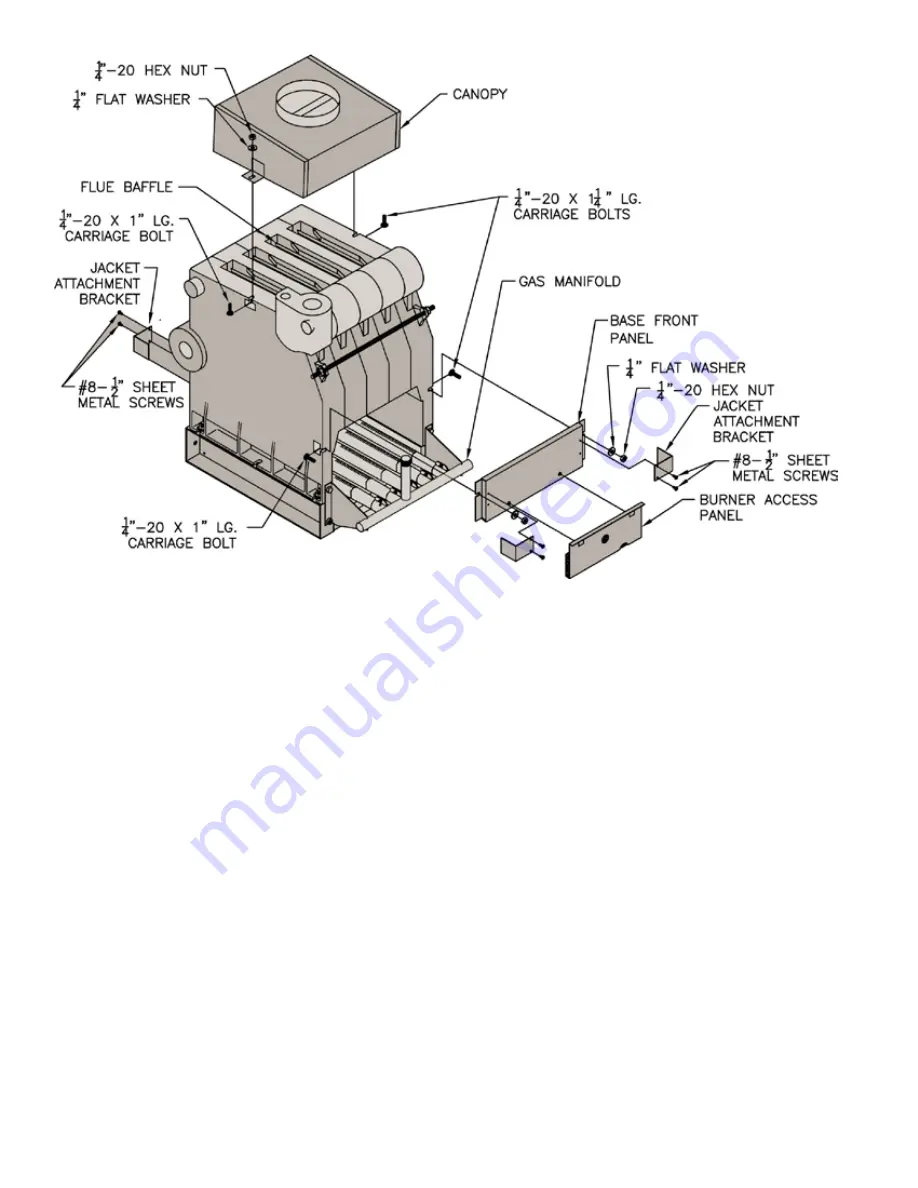

Install Canopy

on section assembly. See Figure 5.

Canopy and hardware are located in Combination

Boiler Parts and Control Carton.

1. Position Canopy on top of Section Assembly. Locate

between end sections and sealing ledge on front and

back of each section.

2. Fasten each end with ¼” - 20 x 1” carriage bolts,

washers and nuts.

3. Seal between Canopy and Section Assembly with

furnace cement.

I.

Inspect joints between sections.

They were factory

sealed. If any openings resulted during shipment or

handling, reseal with furnace cement. Confirm tie rods

are only hand tight to allow for thermal expansion.

J.

Install Base Front Panel.

See Figure 5. Panel and

hardware located in Combination Boiler Parts and

Control Carton.

1. Attach Base Front Panel to Section Assembly using

¼” - 20 x 1¼” carriage bolts, washers and nuts.

2. Seal between top of Base Front Panel and Section

Assembly with furnace cement (shipped in

Combination Boiler Parts and Control Carton).

3. Seal between top of Base Rear Panel and Section

Assembly with furnace cement.

K.

Install Pilot/Main Burner Assembly.

See Figure 7.

Assembly is located in Combination Boiler Parts and

Control Carton. Verify assembly is properly located

on support bracket in Base Rear Panel, seated on Main

Burner Orifice, and secured with hitch pin clip.

L.

Adjust Burner Air Shutters on all Burners.

See

Figure 7. (On Packaged Boilers, Front Door and

Burner Access Panel(s) must be removed to make

adjustments.) Distance between front edge of Burner

Air Shutter and burner mounting ring should be

approximately 11/16”. To adjust this distance, loosen

screw at top of air shutter and slide into correct

position. Then tighten screw. (Replace Burner Access

Panel(s) and Front Door on Packaged Boilers.)

For Packaged Boiler, proceed to Section IV: Water Trim

and Piping.

Figure 5: General Assembly (Knockdown Boilers)

Summary of Contents for 805H

Page 15: ...15 Figure 8 Jacket Assembly...

Page 16: ...16 Figure 9 EP Control Installation...

Page 18: ...18 Figure 10 Schematic Gas Piping 24V Standing Pilot 806H 807HE...

Page 19: ...19 Figure 11 Main Gas Piping Intermittent Ignition EI...

Page 20: ...20 Figure 12 Schematic Pilot Piping Honeywell EI USA...

Page 22: ...22 Figure 14 Schematic Gas Piping EP Control System Natural Gas Only 806H 810HE...

Page 23: ...23 Figure 15 Schematic Gas Piping EP CSD 1 Control System 808HE 810HE...

Page 36: ...36 Figure 27 Wiring Diagram Standing Pilot 24V Continuous Circulation 806H 807HE...

Page 37: ...37 Figure 28 Wiring Diagram Standing Pilot 24V Intermittent Circulation 806H 807HE...

Page 39: ...39 Figure 29 Wiring Diagram Honeywell EI USA Canada 805 Only with Hydrostat 3200 Control...

Page 40: ...40 Figure 30 Wiring Diagram Honeywell EI USA Continuous Circulation 806 810...

Page 41: ...41 Figure 31 Wiring Diagram Honeywell EI USA Intermittent Circulation 806 810...

Page 50: ...50 Figure 40 Lighting Instructions 24V Standing Pilot...

Page 51: ...51 Figure 41 Operating Instructions EI...

Page 52: ...52 Figure 42 Operating Instructions EP...

Page 61: ...61 Honeywell EI Trouble Shooting Guide...

Page 76: ...76...

Page 78: ...78...

Page 82: ...82...

Page 83: ...83...

Page 84: ...84...