100

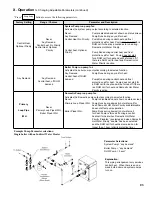

X. Operation

G. Changing Adjustable Parameters (continued)

Factory

Setting

range /

Choices

Parameter and Description

Local

Local,

4-20mA

Central Heat Modulation Source

This parameter enables the 4-20mA input to control firing rate and the thermostat input to control boiler on/off

demand directly without using the internal setpoint. The 4-20mA selection is used to enable a remote multiple boiler

controller to control the Sage2.1 Control:

Local: 4-20mA Input on Terminal 9 & 10 is ignored.

4-20mA 4-20mA Input on Terminal 9 & 10 is used to control firing Rate % directly.

Local

Local,

4-20mA

Central Heat Setpoint Source

Sets the remote (Energy Management System) control mode as follows:

Local: Local setpoint and modulation rate is used. 4-20mA input on Terminal 9 & 10 is ignored.

4-20mA 4-20mA Input on Terminal 9 & 10 is used as the temperature setpoint. The following two

parameters may be used to adjust the signal range.

130°F

80°F -

Central Heat

Setpoint

Central Heat 4-20madc Setup, 4 ma Water Temperature*

Sets the Central Heat Temperature Setpoint corresponding to 4mA for signal input on terminal 9 & 10. Current

below 4mA is considered invalid, (failed or incorrect wired input).

180°F

80°F -

Central Heat

Setpoint

Central Heat 4-20madc Setup, 20 ma Water Temperature*

Sets the Central Heat Temperature Setpoint corresponding to 20mA for signal input on terminal 9 & 10. Current

above 20mA is considered invalid, (failed or incorrect wired input).

* Only visible when Central Heat Setpoint Source is set to 4-20mA.

“Press”

Remote

4-20mA

button to access the following parameters:

“Press”

Sequence

Master

button to access the following parameters:

Factory

Setting

range / Choices

Parameter and Description

Disable

Enable,

Disable

Master Enable/Disable

The Sequencer Master Enable/Disable is used to “turn on” the Multiple Boiler Controller. Warning! enable

ONLY one Sequence Master.

Boiler

Piped

Boiler Piped,

Primary Piped

indirect Water Heater (iWH)

Boiler Piped

Sequencer to respond to an Isolated DHW demand that is piped to a single boiler. The

individual boiler goes on “Leave” from the Sequencer Master and goes to DHW Service.

Primary Piped

The Sequence Master responds to the DHW Call For Heat. This allows one or more

boilers to provide heat to the IWH.

Disabled

Enable,

Disable

DHW Two Boiler Start

The Sequencer to immediately start two boilers for a DHW call for heat. Used when DHW is the largest

demand. Only visible when primary piped IWH is selected.

120 Secs

120 - 1200 Secs

Boiler Start Delay

Slave boiler time delay after header temperature has dropped below the setpoint minus “Diff below” setpoint.

Longer time delay will prevent nuisance starts due to short temperature swings.

195°F

Central Heat

Setpoint,

195°F

Stop all Boilers Setpoint

When this temperature is reached all boilers are stopped. This setpoint allows the Sequencer to respond to

rapid load increases.

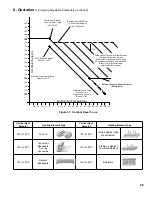

50%

50% - 100%

Base Load Common rate

To maximize condensing boiler efficiency, the firing rate is limited to an adjustable value. Boilers are kept at

or below this firing rate as long as the boilers can handle the load. After last available boiler has started, the

modulation rate limit is released up to 100%.

3

1-5

response Speed

This parameter adjusts the Sequence Master temperature controller Proportion Integral Derivative (PID)

values. Higher values cause a larger firing rate change for each degree of temperature change. If set too

high firing rate “overshoots” required value, increases to high fire causing the temperature to exceed the “Diff

Above” setpoint and cycle the boiler unnecessarily. Lower values cause a smaller firing rate change for each

degree of temperature change. If set too low, the firing rate response will be sluggish and temperature will

wander away from setpoint.

“Press”

Sequence

Slave

button to access the following parameters:

Factory

Setting

range / Choices Parameter and Description

None

1-8

Boiler address

Each boiler must be given a unique address. When ”Normal” slave selection order is used, the boiler address

is used by the Master Sequencer as the boiler start order. The boiler address is also the Modbus Address

when a Energy Management System is connected.

Normal

Use Boiler First,

Normal,

Use Boiler Last

Slave Selection Order

“Use Boiler First”; places the Slave in the lead permanently.

”Normal”; firing order follows boiler number (1,2,3,..) order.

”Use Boiler Last”; places the slave last in the firing order.

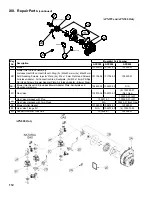

Summary of Contents for Apex APX399

Page 65: ...65 VIII Electrical continued Figure 43 Ladder Diagram ...

Page 66: ...66 VIII Electrical continued ...

Page 67: ...67 Figure 44 Wiring Connections Diagram VIII Electrical continued ...

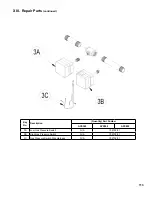

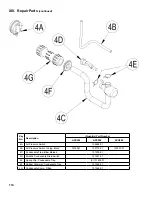

Page 110: ...110 1P 3 1P 2 1P 1 XIII Repair Parts continued 1C 1D 1E ...

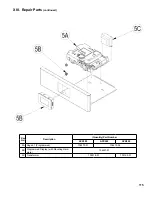

Page 116: ...116 XIII Repair Parts continued ...

Page 118: ...118 XIII Repair Parts continued ...

Page 129: ...129 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 130: ...130 SERVICE RECORD DATE SERVICE PERFORMED ...