108

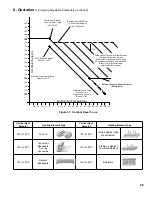

Xii. Troubleshooting

(continued)

G.

Troubleshooting problems where a Hard Lockout Code is displayed.

When a hard lockout occurs, the boiler will shut

down, the display will turn red and the “Help” button will “blink”. Select the “blinking” “Help” button to determine the

cause of the Hard Lockout. Once the condition that caused the lockout is corrected, the boiler will need to be manually reset

using the Reset button on the “Active Fault” display or located on the Sage2.1 Control.

Lockout number

Condition

Possible Cause

4

Supply high limit

Sage2.1 supply sensor detected

temperatures in excess of 210°F.

• Heating load at time of error was far below the minimum firing

rate of the boiler.

• Defective system circulator or no flow in primary loop.

• Defective boiler circulator or no flow in boiler loop.

• Control system miswired so that the boiler operation is

permitted when no zones are calling.

5

DHW high limit

Sage2.1 DHW sensor detected

temperatures in excess of Setpoint.

• DHW load at time of error was far below the minimum firing

rate of the boiler.

• Control system miswired so that boiler operation is permitted

when no DHW are calling.

6

Stack High limit

Sage2.1 Flue gas (Stack) sensor detected

temperatures in excess of 204°F.

• Heat exchanger needs to be cleaned.

• Boiler over-fired.

• Air-fuel mixture out of adjustment - consult factory.

12

Flame detected out of sequence

A flame signal was present when there

should be no flame.

• Defective gas valve - make sure inlet pressure is below

maximum on rating plate before replacing valve.

18

Light off rate proving failed

Blower is not running at Light-off rate

when it should or blower speed signal not

being detected by Sage2.1.

• Loose connection in 120 VAC blower wiring.

• Loose or miswired blower speed harness.

• Defective blower

19

Purge rate proving failed

Blower is not running at Purge rate when

it should or blower speed signal not being

detected by Sage2.1.

• Loose connection in 120 VAC blower wiring.

• Loose or miswired blower speed harness.

• Defective blower

20

Invalid Safety Parameters

Unacceptable Sage2.1 control Safety

related parameter detected.

Safety Parameter verification required. Contact factory.

21

Invalid Modulation Parameter

Unacceptable Sage2.1 control Modulation

related parameter detected.

Reset the control.

22

Safety data verification needed

Safety related parameter change has

been detected and a verification has not

been completed.

Safety related Sage2.1 control parameter has been changed and

verification has not been performed.

23

24VAC voltage low/high

Sage2.1 control 24Vac control power is

high or low.

• Loose connection in 24Vac VAC power wiring.

• Loose or miswired 24Vac harness.

• Miswired wiring harness causing power supply short to

ground.

• Defective transformer.

• Transformer frequency, voltage and VA do not meet

specifications.

24

Fuel Valve Error

Power detected at fuel valve output when

fuel valve should be off.

• Loose or defective gas valve harness. Check electrical

connections.

• Defective gas valve (check for 24 Vac at harness during trial

for ignition before replacing valve).

25

Hardware Fault

Internal control failure.

• Reset the control. If problem reoccurs, replace the Sage.

26

Internal Fault

Internal control failure.

• Reset the control. If problem reoccurs, replace the Sage.

27

Ignition failure

Model APX500 and APX800:

Flame failure after 1 try to restart.

• No gas pressure.

• Gas pressure under minimum value shown on rating plate.

• Gas line not completely purged of air.

• Defective Electrode.

• Loose burner ground connection.

• Defective Ignition Cable.

• Defective gas valve (check for 24 Vac at harness during trial

for ignition before replacing valve).

• Air-fuel mixture out of adjustment - consult factory.

Hard Lockout Codes Displayed

Summary of Contents for Apex APX399

Page 65: ...65 VIII Electrical continued Figure 43 Ladder Diagram ...

Page 66: ...66 VIII Electrical continued ...

Page 67: ...67 Figure 44 Wiring Connections Diagram VIII Electrical continued ...

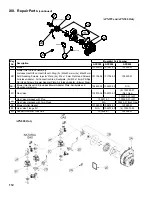

Page 110: ...110 1P 3 1P 2 1P 1 XIII Repair Parts continued 1C 1D 1E ...

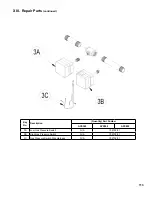

Page 116: ...116 XIII Repair Parts continued ...

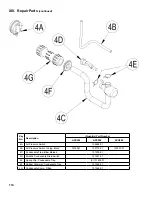

Page 118: ...118 XIII Repair Parts continued ...

Page 129: ...129 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 130: ...130 SERVICE RECORD DATE SERVICE PERFORMED ...