13

iii. Pre-installation and Boiler Mounting

G. General (continued)

H.

Boiler Stacking

1. For installations with unusually high space heating

and/or domestic hot water heating loads, where

employing two (2) Apex (APX) boilers will offer the

benefits of greater operational efficiency, floor space

savings and boiler redundancy, the Apex (APX)

boilers may be installed stacked one on the top of

the other. Refer to Table 3 “Apex (APX) Boiler

Model Stacking Combinations” for details.

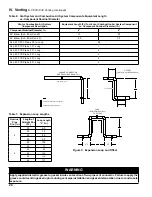

Table 3: apex (aPX) Boiler Model Stacking

Combinations

Bottom

Boiler Model

Top Boiler Model

APX399

APX399

APX500

APX399 or APX500

APX800

APX399, APX500 or APX800

2.

To field assemble individual Apex (APX) boilers

into a stackable configuration

, use the steps below:

a. Position the bottom boiler first. Refer to Sections

II “Unpacking Boiler” and III “Pre-Installation

& Boiler Mounting” of the manual for details.

Always position higher input boiler model as

bottom boiler

.

b. Each Apex (APX) boiler is factory packaged

with two (2) Stacking Boiler Attachment

Brackets (P/N 101679-01) and the bracket

mounting hardware [six (6) self-drilling hex

washer head plated #8 x ½” long screws, P/N

80860743]. Locate and remove the brackets and

the hardware. The Stacking Boiler Attachments

Bracket has three 7/32” diameter holes punched

in a triangular pattern. See Figure 3 “Stacking

Boiler Attachment Bracket Placement”.

c. Apex (APX) boiler left and right side panels

have a series of dimples at panel top and bottom.

These dimples are positioning dimples for

Stacking Boiler Attachment Bracket mounting

screws. Side panel bottom positioning dimples

are evenly spaced from boiler front and back,

while side panel top positioning dimples follow

specific pattern to compensate for Apex (APX)

boiler model variable depth.

d. Position the upper boiler on the top of the bottom

boiler and align boiler front doors and sides flush

with each other.

• Place first Stacking Boiler Attachment

Bracket onto the upper boiler left side panel,

at the panel lower left corner and align

bracket two upper holes with corresponding

side panel lower dimples.

• The remaining lower bracket hole must align

with a matching bottom boiler left side panel

top positioning dimple.

• Once bracket holes and side panel dimple

alignment is verified, attach the bracket to

top and bottom boiler left side panels with

the mounting screws.

e. Repeat above procedure to install second

Stacking Boiler Attachment Bracket and secure

the stacked boiler right side panels together at

the front right corner.

f. Install the third Stacking Boiler Attachment

Bracket to secure top and bottom boiler left side

panels at the rear left corner. Align the bracket

holes with corresponding positioning dimples in

the top boiler and bottom boiler left side panels,

then secure bracket with the screws.

g. Repeat above procedure to install the forth

Stacking Boiler Attachment Bracket to secure

stacked boiler right side panels at the rear right

corner.

3.

When installing stackable boiler combinations

observe the following guidelines:

a. Venting - Top and bottom boilers must have their

individual vent piping and vent terminals.

Warning

no common manifolded venting is permitted.

For side-wall venting individual model vent

terminals must terminate not closer than 12

inches horizontally and three (3) feet vertically

from each other in order to prevent combustion

air contamination. For vertical through the roof

venting, individual vertical vent terminals, if

level with each other, must be spaced no closer

than 12 inches horizontally. If vertical terminals

cannot end in one plane, they must be spaced no

closer than three (3) feet horizontally.

Chimney chase concentric venting is permitted

for modules, when stackable, providing

concentric vertical (roof) vent terminals, if level

with each other, are spaced no closer then 12

inches horizontally.

If vertical vent terminals cannot end in one

plane, they must be spaced no closer then three

(3) feet horizontally.

Follow instructions in Section IV “Venting”

of the manual for specifics of individual boiler

vent termination. Follow instructions in Section

V “Condensate Disposal” for each individual

boiler flue gas condensate line construction and

condensate disposal. Terminating individual

boiler condensate lines into common pipe prior

to drain disposal is permissible, providing

common pipe has sufficient flow capacity

to handle combined condensate volume of

stackable combination.

Summary of Contents for Apex APX399

Page 65: ...65 VIII Electrical continued Figure 43 Ladder Diagram ...

Page 66: ...66 VIII Electrical continued ...

Page 67: ...67 Figure 44 Wiring Connections Diagram VIII Electrical continued ...

Page 110: ...110 1P 3 1P 2 1P 1 XIII Repair Parts continued 1C 1D 1E ...

Page 116: ...116 XIII Repair Parts continued ...

Page 118: ...118 XIII Repair Parts continued ...

Page 129: ...129 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 130: ...130 SERVICE RECORD DATE SERVICE PERFORMED ...