28

iV. Venting

C. Polypropylene Venting (continued)

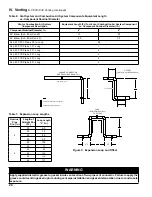

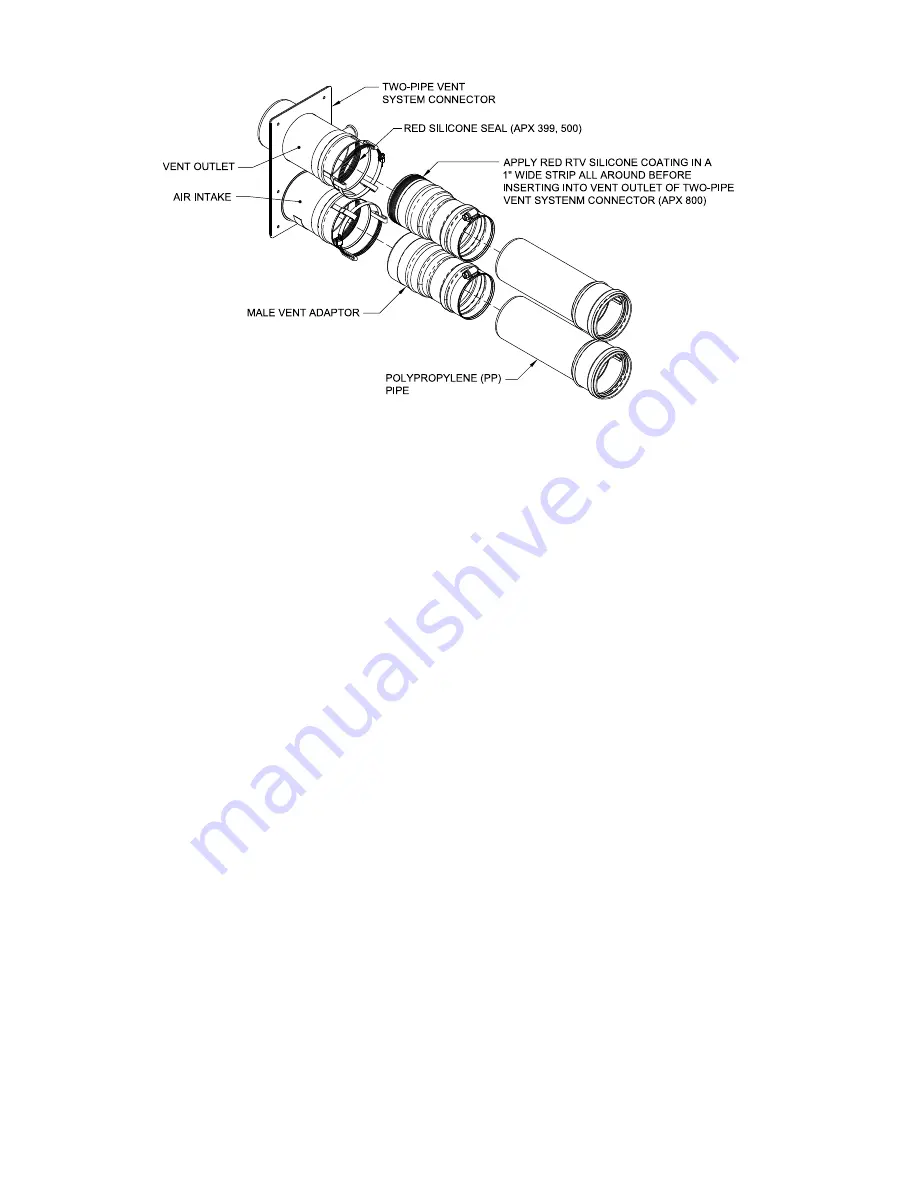

Figure 14: Vent System Field Modification to Install PVC to PP Adapter (M&G/DuraVent Shown)

3) Tighten the worm band clamp screw to secure PVC

to PP boiler adapter.

4) Do not install PVC to PP boiler adapter at the

lower combustion air supply port of the two-pipe

vent system connector when using PVC pipe for

combustion air supply to boiler.

5)

APX800 model

- Apply a coating of supplied red

RTV silicon sealant, at least 1” wide, to PVC to PP

boiler adapter (6PPS-06PVCM-6PPF) male end,

when used for combustion product venting.

If polypropylene pipe is also used for combustion air

supply, application of the silicon sealant to PVC to

PP boiler adapter (6PPS-06PVCM-6PPF) male end

is not required.

6)

APX800 model

- Push and twist PVC to PP boiler

adapter (6PPS-06PVCM-6PPF) into two-pipe vent

system connector vent port or air supply port until

bottomed out.

7) Tighten the worm band clamp screw to secure PVC

to PP boiler adapter.

8) Do not install PVC to PP boiler adapter at the

lower combustion air supply port of the two-pipe

vent system connector when using PVC pipe for

combustion air supply to boiler.

When using

Centrotherm Eco

polypropylene pipe

for combustion product venting and/or air supply PVC

to PP boiler adapter (ISAA0404 or ISAAL0404 and

ISAA0606 or ISAAL0606 as applicable) is installed

into the two-pipe vent system connector vent or

combustion air supply port as follows (see Figure 14):

9)

APX399 and APX500 models

- Apply provided

dielectric grease (grease pouch taped to the vent

system connector) all around to the vent or air

connection inner red silicon gasket.

10)

APX399 and APX500 models

- Push and

twist PVC to PP boiler adapter (ISAA0404 or

ISAAL0404) into two-pipe vent system connector

vent connection or air supply port until bottomed

out.

11) Tighten the worm band clamp screw to secure PVC

to PP boiler adapter.

12) Do not install PVC to PP boiler adapter at the

lower combustion air supply port of the two-pipe

vent system connector when using PVC pipe for

combustion air supply to boiler.

13)

APX800 model

- Apply a coating of supplied red

RTV silicon sealant, at least 1” wide, to PVC to PP

boiler adapter (ISAA0606 or ISAAL0606) male

end,

when used for combustion product venting.

If polypropylene pipe is also used for combustion air

supply, application of the silicon sealant to PVC to

PP boiler adapter (ISAA0606 or ISAAL0606) male

end is not required.

14)

APX800 model

- Push and twist PVC to PP boiler

adapter (ISAA0606 or ISAAL0606) into two-pipe

vent system connector vent port or air supply port

until bottomed out.

15) Tighten the worm band clamp screw to secure PVC

to PP boiler adapter.

16) Do not install PVC to PP boiler adapter at the

lower combustion air supply port of the two-pipe

vent system connector when using PVC pipe for

combustion air supply to boiler.

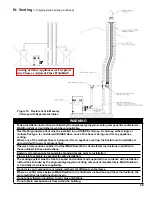

Optional Two-pipe Vertical Venting Installation –

Running Flexible Polypropylene Vent (Liner)

Thru Unused Chimney Chase (see Figure 15).

Apex APX399 and APX500 boilers are approved for

vertical venting by installing Flexible Vent in an UNUSED

masonry chimney/chase and supplying combustion air

thru a separate wall or roof air intake terminal.

Summary of Contents for Apex APX399

Page 65: ...65 VIII Electrical continued Figure 43 Ladder Diagram ...

Page 66: ...66 VIII Electrical continued ...

Page 67: ...67 Figure 44 Wiring Connections Diagram VIII Electrical continued ...

Page 110: ...110 1P 3 1P 2 1P 1 XIII Repair Parts continued 1C 1D 1E ...

Page 116: ...116 XIII Repair Parts continued ...

Page 118: ...118 XIII Repair Parts continued ...

Page 129: ...129 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 130: ...130 SERVICE RECORD DATE SERVICE PERFORMED ...