83

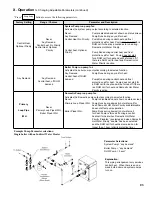

X. Operation

C. Boiler Protection Features (continued)

C.

Boiler Protection Features

1.

Supply Water Temperature High Limit

The boiler is equipped with independent automatic reset

and a manual reset High Limit devices. The automatic

reset high limit is provided by a supply manifold mounted

Limit Device. The automatic high limit is set to 200°F.

The Control monitors a supply water temperature sensor

that is also mounted in the supply water manifold and

supplies an internal, manual reset high limit. If supply

water temperature exceeds 190°F, the control begins

to reduce the blower maximum speed setting. If the

temperature exceeds 200°F, a forced recycle results.

If the temperature exceeds 210°F, a manual reset hard

lockout results. Additionally, if the supply temperature

rises faster than the degrees Fahrenheit per second limit

a soft lockout is activated.

2.

High Differential Temperature Limit

The Control monitors the temperature difference between

the return and supply sensors. If this difference exceeds

43°F the control begins to reduce the maximum blower

speed. If temperature difference exceeds 53°F a forced

boiler recycle results. If the temperature difference

exceeds 63°F the control will shut the unit down. The

unit will restart automatically once the temperature

difference has decreased and the minimum off time has

expired.

3.

Low Water Cut Off

(

LWCO)

The Control shuts down the boiler when either the

supply water temperature is too high or supply to return

temperature differential temperature is too high. This

ensures the boiler is shutdown in the event of a low water

level or low water flow condition.

Some codes and jurisdiction may accept these integral

features instead of requiring a low water cutoff. ADHERE

TO ALL LOCAL CODE REQUIREMENTS. Contact

your local code inspector prior to installation. If required, a

LWCO four-position wire harness connection is provided

for an external LWCO kit (p/n 102097-01) to be added.

If the LWCO opens, the boiler will shut down and an

open limit indication and error code is provided. If the

limit installed is a manual reset type, it will need to be

reset before the boiler will operate.

4.

Return Temperature Higher Than Supply Temperature

(Inversion Limit)

The Control monitors the supply and return temperature

sensors. If the return water temperature exceeds the

supply water temperature for longer than a limit time

delay the Control shuts down the boiler and delays

restart. If the inverted temperature is detected more than

five times the boiler manual reset Hard Lockout is set.

This condition is the result of incorrectly attaching the

supply and return piping.

5.

External Limit

An external limit control can be installed between

terminals 11 and 12 on the low voltage terminal strip.

Be sure to remove the jumper when adding an external

limit control to the system. If the external limit opens, the

boiler will shut down and an open limit indication and

error code is provided. If the limit installed is a manual

reset type, it will need to be reset before the boiler will

operate.

6.

Boiler Mounted Limit Devices

The Control monitors individual limit devices: pressure

switch, high limit device, condensate level switch,

Thermal Link, Burner Door Thermostat with manual

reset, low water cutoff (optional), fuel gas pressure

switches (optional) and external limit (optional). If any

of these limits opens, the boiler will shut down and an

individual open limit indication is provided.

7.

Stack High Limit

The Control monitors the flue gas temperature sensor

located in the vent connector. If the flue temperature

exceeds 184°F, the control begins to reduce the maximum

blower speed. If the flue temperature exceeds 194°F, a

forced boiler recycle results. If the flue temperature

exceeds 204°F, the control activates a manual reset Hard

Lockout.

8.

Ignition Failure

The Control monitors ignition using a burner mounted

flame sensor. In the event of an ignition failure:

• APX399 - the control retries five (5) times and

then goes into soft lockout for one hour.

• APX500 and APX800 - the control retries one (1)

time and then goes into hard lockout. Manual reset

is required to resume boiler operation.

9.

Central Heating System Frost Protection

When enabled, Frost Protection starts the boiler and

system pump and fires the boiler when low outside air

and low supply water temperatures are sensed. The

Control provides the following control action when frost

protection is enabled:

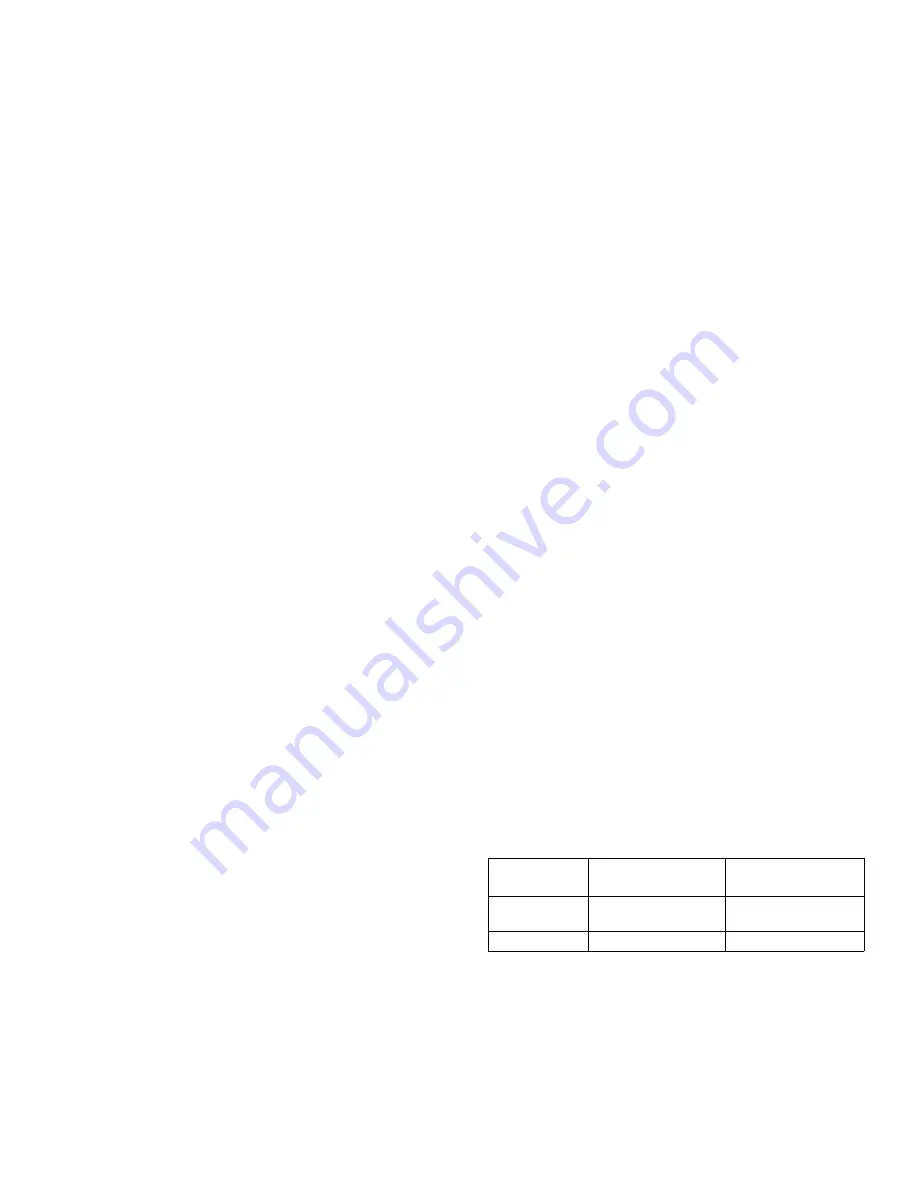

Device

Started

Start

Temperatures

Stop

Temperatures

Boiler & System

Pump

Outside Air < 0°F

Supply Water < 45°F

Outside Air > 4°F

Supply Water > 50°F

Boiler

Supply Water < 38°F

Supply Water > 50°F

Table 28: Frost Protection

FROST PROTECTION NOTE

The Control helps provide freeze protection for the boiler water.

Boiler flue gas condensate drain is not protected from freezing.

Since the Control only controls the system and boiler circulators

individual zones are not protected. It is recommended that the

boiler be installed in a location that is not exposed to freezing

temperatures.

Summary of Contents for Apex APX399

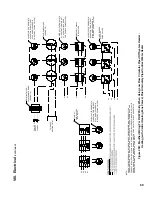

Page 65: ...65 VIII Electrical continued Figure 43 Ladder Diagram ...

Page 66: ...66 VIII Electrical continued ...

Page 67: ...67 Figure 44 Wiring Connections Diagram VIII Electrical continued ...

Page 110: ...110 1P 3 1P 2 1P 1 XIII Repair Parts continued 1C 1D 1E ...

Page 116: ...116 XIII Repair Parts continued ...

Page 118: ...118 XIII Repair Parts continued ...

Page 129: ...129 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 130: ...130 SERVICE RECORD DATE SERVICE PERFORMED ...