1

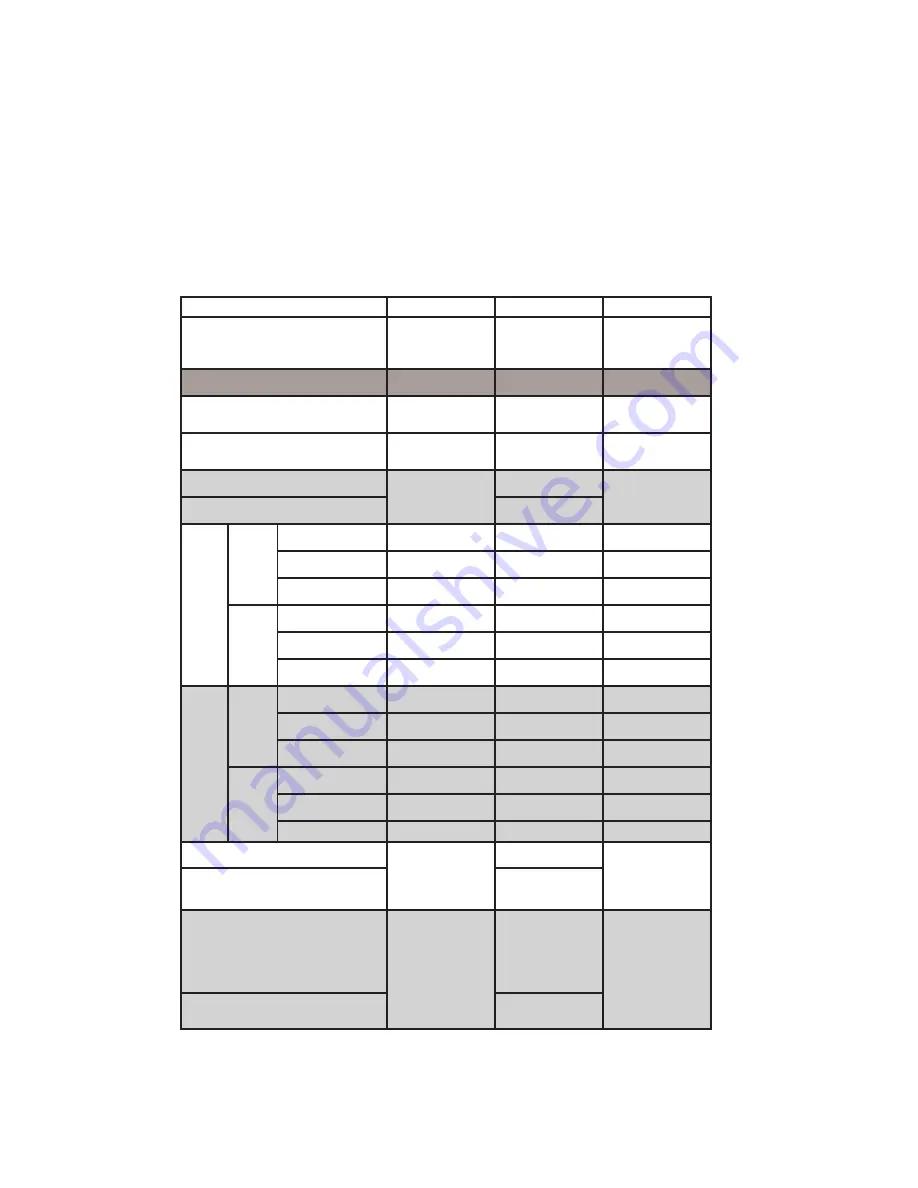

TablE 7.1: suMMarY OF HOriZOnTal VEnTing OPTiOns

VENT OPTION #

1

2

3

CLASSIFICATION USED IN THIS

MANUAL

HORIZONTAL

CONCENTRIC

HORIZONTAL

TWIN PIPE

HORIZONTAL

CONCENTRIC

ILLUSTRATED IN FIGURE

7.2

7.3

7.2

VENT PIPE PENETRATION

THROUGH STRUCTURE

WALL

WALL

WALL

AIR INTAKE PIPE PENETRATION

THROUGH STRUCTURE

WALL

WALL

WALL

VENT PIPE SIZE

60/100 mm

CONCENTRIC

3”

80/125mm

CONCENTRIC

AIR INTAKE PIPE SIZE

3”

MAXIMUM

LENGTH

VENT

FCM070

32ft

55ft

55ft

FCM090

32ft

55ft

55ft

FCM120

18ft

55ft

55ft

INLET

FCM070

32ft

55ft

55ft

FCM090

32ft

55ft

55ft

FCM120

18ft

55ft

55ft

MINIMUM

LENGTH

VENT

FCM070

10in

2ft

2ft

FCM090

10in

2ft

2ft

FCM120

10in

2ft

2ft

INLET

FCM070

10in

2ft

2ft

FCM090

10in

2ft

2ft

FCM120

10in

2ft

2ft

VENT TERMINAL

60/100 mm

CONCENTRIC

P/N 8110701

P/N 101494-01

CONCENTRIC

or P/N 101544-01

SNORKEL

AIR INTAKE TERMINAL

3” 90 ELBOW

VENT MATERIAL

U.S. Boiler

60/100mm VENT

COMPONENTS

SHOWN IN

TABLE 7.4a

(Note #1)

APPROVED

STAINLESS

STEEL VENT

SYSTEM SHOWN

IN TABLE 7.5

U.S. Boiler

80/125mm VENT

COMPONENTS

SHOWN IN

TABLE 7.4b

AIR INTAKE MATERIAL

GALVANIZED OR

PVC

Note #1: In Vent Option #1, the 80/125mm concentric straight section (P/N 101162-01) shown in Table 7.4a may be used

between the boiler and the first 80/125 x 60/100 reducing elbow. If this is done, the overall maximum vent length is still

restricted to that shown for Vent Option #1 in Table 7.1 above.

Horizontal Terminal Clearance Requirements (Continued):

• Vent terminal must be at least 6 feet from an inside corner.

• Under certain conditions, water in the flue gas may condense, and possibly freeze, on objects around the vent terminal

including on the structure itself. If these objects are subject to damage by flue gas condensate, they should be moved or

protected.

• If possible, install the vent and air intake terminals on a wall away from the prevailing wind. Reliable operation of this

boiler cannot be guaranteed if these terminals are subjected to winds in excess of 40 mph.

• Air intake terminal must not terminate in areas that might contain combustion air contaminates, such as near swimming

pools. See Section IV for

more information on possible contaminates.

Summary of Contents for FREEDOM

Page 8: ...8 Figure 1 Wall Mounting Hole locations ...

Page 9: ...9 Figure 5 2 Boiler Mounting Hardware ...

Page 11: ...11 Figure 6 1 Boiler Installed In A Confined Space Ventilation Air From Inside ...

Page 42: ...42 FIGURE 7 51 CONDENSATE PIPING ARRANGEMENT ...

Page 55: ...55 Figure 10 1 Wiring Connections Diagram ...

Page 56: ...56 Figure 10 2 Ladder Diagram ...

Page 57: ...57 Figure 10 3 Wiring of Isolation Relay for Control of Two Heating Circulators ...

Page 60: ...60 FCM Series Lighting and Operating Instructions ...

Page 66: ...66 FIGURE 12 2 BASIC MENU TREE ...

Page 75: ...75 ...

Page 77: ...77 ...

Page 79: ...79 ...

Page 80: ...80 ...

Page 81: ...81 ...

Page 83: ...83 150 151 152 153 154 155 ...

Page 84: ...84 156 157 158 159 160 161 ...

Page 85: ...85 162 ...