13

III. Semi-Pak Boiler Assembly

G

N

I

N

R

A

W

e

b

d

l

u

o

h

s

r

e

li

o

b

s

i

h

t

f

o

n

o

i

t

a

ll

a

t

s

n

I

d

e

ll

i

k

s

d

n

a

d

e

n

i

a

r

t

y

b

y

l

n

o

n

e

k

a

t

r

e

d

n

u

.

y

c

n

e

g

a

e

c

i

v

r

e

s

d

e

i

f

il

a

u

q

a

m

o

r

f

l

e

n

n

o

s

r

e

p

A.

Remove Crate

1. Remove all hold down screws and brackets.

2. Slide boiler to rear of skid and carefully remove

from crate skid onto 2 inch thick piece of wood and

then onto floor. Do not bump boiler jacket against

floor.

3. Do not drop boiler at any time.

B.

Move Boiler To Permanent Position.

Refer to Section

I: Pre-Installation.

C.

Identify Trim and Controls

FIRST - Determine controls ordered with boiler and

refer to appropriate section(s) following:

There are two ordering methods for trim and controls:

l. EZ–Connect Carton (either steam or water) includes

trim, controls, wiring and wiring instructions for

installation.

2. Separate Trim Carton (steam or water) and Control

Carton (steam or water). Only wiring requiring

special connections is provided. For wiring

requirements, refer to Section VIII: Electrical and

appropriate wiring diagram.

D.

Install Trim and Controls

Refer to appropriate paragraphs (following) for trim

and controls to be installed.

1.

Steam Boiler with Probe Low Water Cutoff

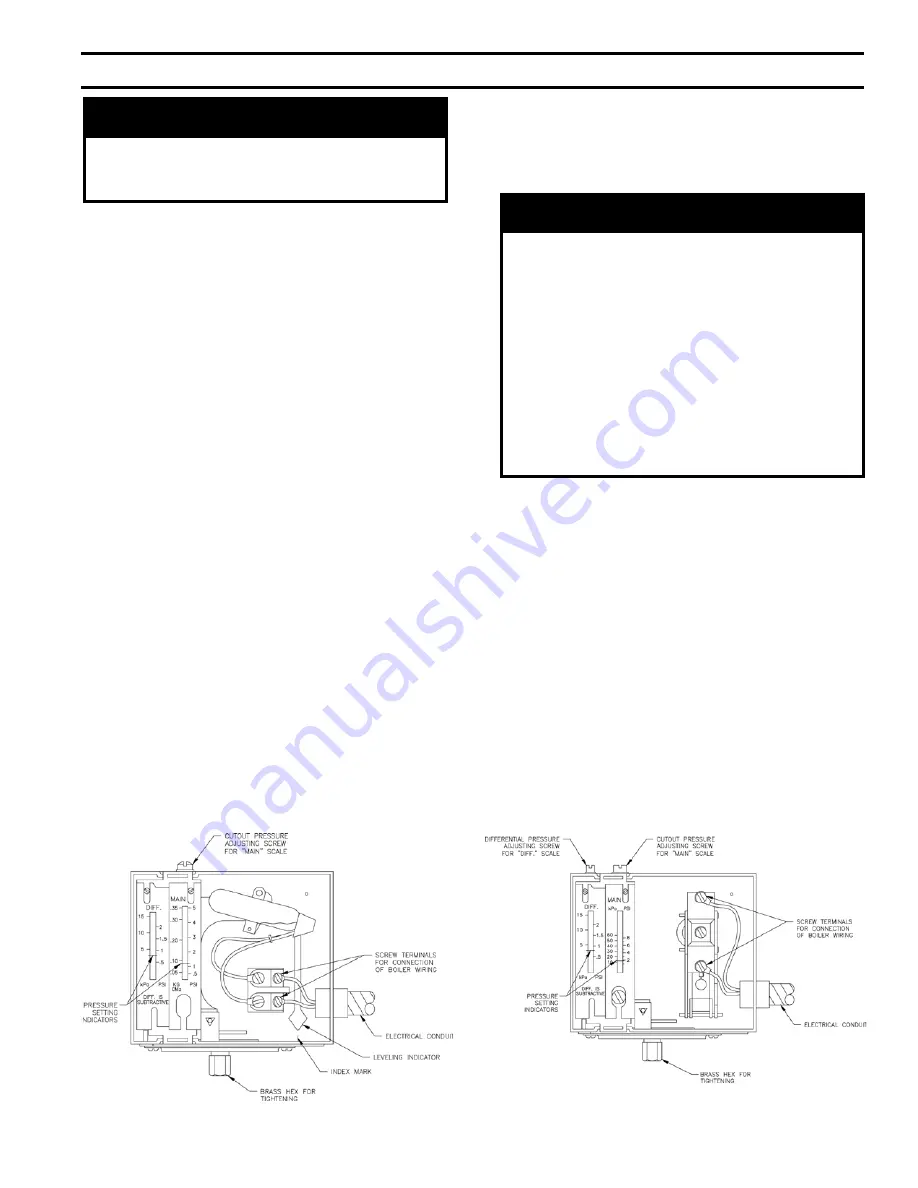

a. Install pressure limit control into Tapping "H"

with siphon, ¾" x ¼" hex bushing, ¾" elbow and

¾" x 3" nipple provided. See Figures 1 and 2.

DO NOT TWIST CONTROL. Use wrench on

hex fitting located at bottom of control. See

Figure 18A or 18B.

b. Level the L404A pressure limit by carefully

bending the syphon until the limit's leveling

indicator hangs freely with its pointer directly

over the index mark inside the back of the case.

See Figure 18A.

E

C

I

T

O

N

a

n

i

y

r

u

c

r

e

m

n

i

a

t

n

o

c

s

t

i

m

i

L

e

r

u

s

s

e

r

P

A

4

0

4

L

o

D

.

e

b

u

t

d

e

l

a

e

s

t

o

n

h

s

a

r

t

e

h

t

n

i

t

i

m

il

e

c

a

l

p

.

e

f

il

l

u

f

e

s

u

s

t

i

f

o

d

n

e

e

h

t

t

a

s

n

i

a

t

n

o

c

t

a

h

t

t

i

m

il

a

g

n

i

c

a

l

p

e

r

s

i

t

i

m

il

s

i

h

t

f

I

o

d

,

e

b

u

t

d

e

l

a

e

s

a

n

i

y

r

u

c

r

e

m

t

o

n

r

u

o

y

e

c

a

l

p

.

h

s

a

r

t

e

h

t

n

i

t

i

m

il

d

l

o

t

n

e

m

e

g

a

n

a

m

e

t

s

a

w

l

a

c

o

l

r

u

o

y

t

c

a

t

n

o

C

g

n

i

d

r

a

g

e

r

s

n

o

i

t

c

u

r

t

s

n

i

r

o

f

y

t

i

r

o

h

t

u

a

s

i

h

t

f

o

l

a

s

o

p

s

i

d

r

e

p

o

r

p

e

h

t

d

n

a

g

n

il

c

y

c

e

r

n

i

y

r

u

c

r

e

m

g

n

i

n

i

a

t

n

o

c

t

i

m

il

d

l

o

n

a

f

o

r

o

,

t

i

m

il

.

e

b

u

t

d

e

l

a

e

s

a

t

a

.

c

n

I

ll

e

w

y

e

n

o

H

ll

a

c

,

s

n

o

i

t

s

e

u

q

e

v

a

h

u

o

y

f

I

.

2

0

5

1

-

8

6

4

-

0

0

8

-

1

c. The L404F pressure limit employs a snap action

switch and does not require leveling. See Figure

18B.

d. Install pressure gauge into Tapping "B" (½ NPT

bushed to ¼ NPT). See Figures 1 and 2. Tighten

with wrench applied to square shank on back of

gauge. DO NOT APPLY PRESSURE ON

GAUGE CASE since this may destroy

calibration of gauge.

e. Install Low Water Cutoff Probe into Tapping "K"

(¾ NPT). HANDLE PROBE WITH CARE.

f. Attach Low Water cutoff Control to Probe by

following instructions packed with control.

g. Install gauge glass fittings into Tappings "C"

(½ NPT). See Figures 1 and 2. Lower fitting has

small drain valve.

Figure 18B: L404F Pressure Limit Control

Figure 18A: L404A Pressure Limit Control

Summary of Contents for Independence

Page 4: ... Figure 1 Dimensional Drawing ...

Page 19: ...19 Figure 25 Recommended Water Piping for Circulator Zoned Heating System ...

Page 20: ...20 Figure 25A Recommended Water Piping for Zone Valve Zoned Heating System ...

Page 29: ...29 Figure 34 Vent Damper Schematic Wiring Diagram Figure 33 Vent Damper Harness to Limit ...

Page 30: ...30 Figure 35 Wiring Diagrams Steam Continuous Ignition Standing Pilot Probe Low Water Cutoff ...

Page 32: ...32 Figure 36 Wiring Diagrams Steam Intermittent Ignition EI Probe Low Water Cutoff ...

Page 34: ...34 Figure 37 Wiring Diagrams Steam Intermittent Ignition HSP Probe Low Water Cutoff ...

Page 36: ...36 Figure 38 Wiring Diagrams Steam Continuous Ignition Standing Pilot Float Low Water Cutoff ...

Page 38: ...38 Figure 39 Wiring Diagrams Steam Intermittent Ignition EI Float Low Water Cutoff ...

Page 40: ...40 Figure 40 Wiring Diagrams Steam Intermittent Ignition HSP Float Low Water Cutoff ...

Page 44: ...44 Figure 42 Wiring Diagrams Water Intermittent Ignition EI Intermittent Circulation ...

Page 46: ...46 Figure 43 Wiring Diagrams Water Intermittent Ignition HSP Intermittent Circulation ...

Page 48: ...48 Figure 44 Wiring Diagrams Water Continuous Ignition Standing Pilot Gravity Circulation ...

Page 50: ...50 Figure 45 Wiring Diagrams Water Intermittent Ignition EI Gravity Circulation ...

Page 52: ...52 Figure 46 Wiring Diagrams Water Intermittent Ignition HSP Gravity Circulation ...

Page 54: ...54 Figure 47 Wiring Diagrams Water Continuous Ignition Standing Pilot Tankless Heater ...

Page 56: ...56 Figure 48 Wiring Diagrams Water Intermittent Ignition EI Tankless Heater ...

Page 58: ...58 Figure 49 Wiring Diagrams Water Intermittent Ignition HSP Tankless Heater ...

Page 61: ...61 Figure 53 Lighting Instructions Continuous Ignition System VR8200 and VR8300 Gas Valves ...

Page 62: ...62 Figure 54 Lighting Instructions Continuous Ignition System 7000 ERHC Gas Valve ...

Page 65: ...65 Figure 57 Operating Instructions Intermittent Ignition System HSP SV9501 and SV9601 ...

Page 76: ...76 ...

Page 77: ...77 Honeywell Hot Surface to Pilot Trouble Shooting Guide ...

Page 91: ...91 THIS PAGE LEFT BLANK INTENTIONALLY ...

Page 92: ...92 ...

Page 96: ...96 ...

Page 99: ...99 THIS PAGE LEFT BLANK INTENTIONALLY ...

Page 100: ...100 ...