E. A hot water boiler installed above radiation level

must be provided with a low water cutoff device as

part of the installation.

If a low water cut-off is required, it must be mount-

ed in the system piping above the boiler.

The minimum safe water level of a hot water boiler

is just above the highest water containing cavity of

the boiler; that is, a hot water boiler must be full of

water to operate safely.

F. There are many possible causes of oxygen contami-

nation such as:

(1) Addition of excessive make-up water as a

result of system leaks.

(2) Absorption through open tanks and fittings.

(3) Oxygen permeable materials in the distribution

system.

In order to insure long product life, oxygen sources

should be eliminated. This can be accomplished by

taking the following measures:

(1) Repairing system leaks to eliminate the need

for addition of make-up water.

(2) Eliminating open tanks from the system.

(3) Eliminating and/or repairing fittings which

allow oxygen absorption.

(4) Use of non-permeable materials in the distribu-

tion system.

(5) Isolating the boiler from the system water by

installing a heat exchanger.

N

O

I

T

U

A

C

ll

i

w

r

e

t

a

w

r

e

li

o

b

f

o

n

o

i

t

a

n

i

m

a

t

n

o

c

n

e

g

y

x

O

r

e

li

o

b

l

e

e

t

s

d

n

a

n

o

r

i

f

o

n

o

i

s

o

r

r

o

c

e

s

u

a

c

.

e

r

u

li

a

f

r

e

li

o

b

o

t

d

a

e

l

n

a

c

d

n

a

,

s

t

n

e

n

o

p

m

o

c

t

o

n

s

e

o

d

y

t

n

a

r

r

a

w

d

r

a

d

n

a

t

s

s

'

m

a

h

n

r

u

B

n

e

g

y

x

o

y

b

d

e

s

u

a

c

s

m

e

l

b

o

r

p

r

e

v

o

c

.

r

e

t

a

w

r

e

li

o

b

f

o

n

o

i

t

a

n

i

m

a

t

n

o

c

4.

INSTALL BOILER CONTROL.

A. Pull bulb and capillary tube out of hole in back of

control. Insert bulb in immersion well on top of

boiler and secure control with set screw in control.

B. Secure flexible conduit to Jacket Wrapper side with

conduit clamp and sheet metal screw. Conduit must

be on same side of boiler as Swing Door hinges.

5.

MOVE BOILER TO PERMANENT POSITION by

sliding or walking.

6.

INSPECT FRONT AND REAR DOOR INSULATION

PIECES AND COMBUSTION CHAMBER LINER

A. OPEN SWING DOOR on front of boiler. Use

flashlight to inspect insulation pieces secured to

front and rear doors. Inspect Ceramic Fiber Blanket

secured to bottom of combustion chamber with

water glass adhesive. Replace any damaged pieces.

7.

CONNECT SUPPLY AND RETURN PIPING TO

HEATING SYSTEM

A. Hot water pipes shall have clearances of at least ½”

from all combustible construction.

B. Use a system by-pass if the boiler is to be operated

in a system which has a large volume or excessive

radiation where low boiler water temperatures may

be encountered (i.e. converted gravity circulation

system, etc.).

Valves should be located in the by-pass and return

line as illustrated in Figures 4 and 5 in order to

regulate water flow for maintenance of higher

boiler water temperature.

Set the by-pass and return valves to a half throttle

position to start. Operate boiler until the system

water temperature reaches its normal operating

range.

Adjust the valves to maintain 180°F to 200°F boiler

water temperature and greater than 120°F return

temperature. Adjust both valves simultaneously.

Closing the boiler return valve while opening the

by-pass valve will raise the boiler return tempera-

ture. Opening the boiler return valve while closing

the by-pass valve will lower the boiler return

temperature.

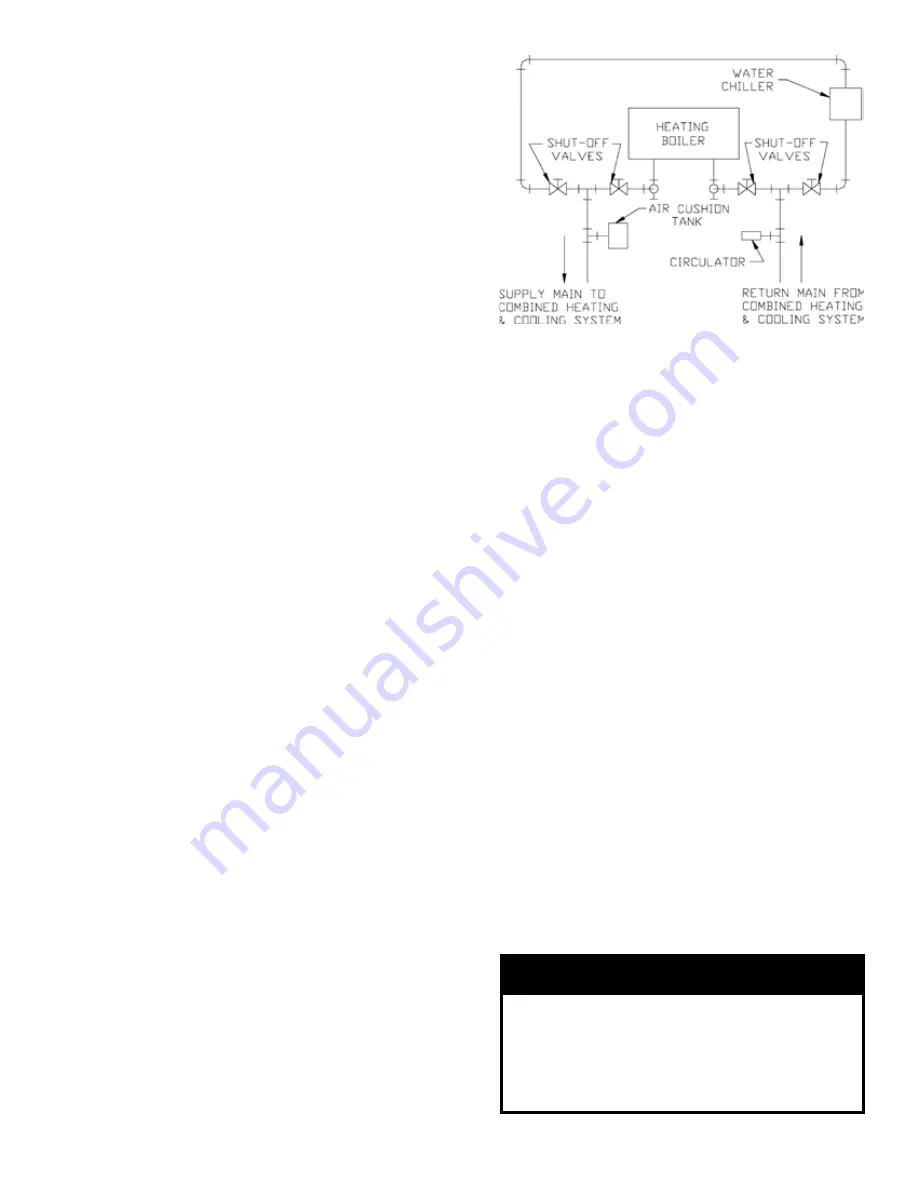

C. If this boiler is used in connection with refrigeration

systems, the boiler must be installed so that the

chilled medium is piped in parallel with the heating

boiler using appropriate valves to prevent the

chilled medium from entering the boiler, see Figure

6. Also consult I=B=R Installation and Piping

Guides.

D. If this boiler is connected to heating coils located in

air handling units where they may be exposed to

refrigerated air the boiler piping must be equipped

with flow control valves to prevent gravity circula-

tion of boiler water during the operation of the

cooling system.

Figure : Recommended Piping for

Combination Heating & Cooling

(Refrigeration) Systems