11

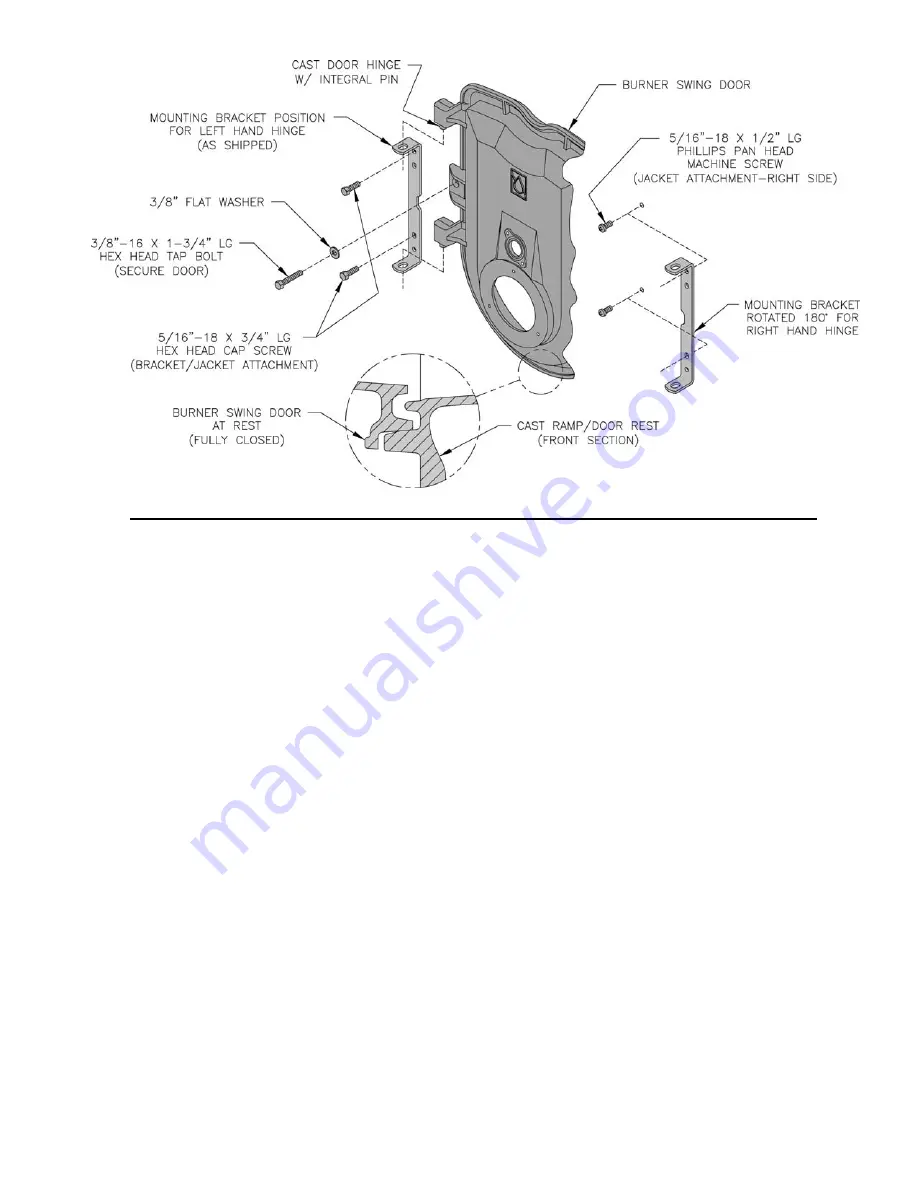

Figure 4A: Partial Front View - Burner Swing Door Mounted to Boiler - Fully Closed and Secured

Step 2.

Loosen and remove right side latching

hardware (5/16" x 1-3/4" lg. tap bolt and

washer).

Step 3.

Remove left side latching hardware (5/16" x

1-3/4" lg. tap bolt and washer).

Step 4.

Disconnect burner power cord from

receptacle located in lower right corner of jacket

front panel.

Step 5.

Door can be swung to the fully open

position, approximately 90° to 120°, with the

burner mounted providing that there is 19" of

clearance to the adjacent wall, see Figure 1.

NOTE:

If reduced clearance prevents the door

from opening fully, one of the following can

provide full access:

a. Burner can be removed to allow full rotation

of door.

b. Door with burner mounted can be lifted

off mounting bracket and set aside during

servicing.

c. The door mounting hardware is reversible

from left side hinge (as shipped) to right side

hinge.

To reverse hinge arrangement (see Figure

4A):

•

Lift door off mounting bracket and set

aside.

•

Remove mounting bracket and hardware

from left side.

•

Remove upper jacket front panel retaining

screw (5/16" x 1/2" lg. Phillip Pan head

machine screw) from right side of door

and re-install in vacated upper mounting

bracket tapping. Do not tighten.

•

Move lower jacket panel retaining screw

from right side to left tapping. Do not

tighten.

•

Rotate door mounting bracket 180°.

Insert 5/16" cap screw through top hole in

bracket and install in upper vacated jacket

hole on right side of door.

•

Install second 5/16" cap through bracket

hole into lower vacated tapping on right

side.

•

Tighten both sets of hardware to secure

jacket and mounting bracket.

•

Lift door and place integral cast hinge

pins on door into slotted mounting bracket

holes.

2. Perform routine inspection, service or cleaning as

necessary.

3. To close Burner Swing Door (see Figures 4A and

4B):

Step 1.

From the fully open position, rotate Burner

Swing Door to the closed position.

Step 2.

If necessary, place your right hand under

the burner air tube to lift upward. Lift the

door up unto the built-in cast ramp/door rest

Summary of Contents for MPO Series

Page 6: ...6 Figure 1 MPO 84 Thru MPO 231 Water Boiler ...

Page 22: ...22 Figure 13A Water Boiler Piping for Circulator Zoned Heating System Supply Side Circulator ...

Page 38: ...38 Figure 27 L1 L2 and V1 Head Electrode Positioning and Gun Setting Beckett AFG ...

Page 49: ...49 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 50: ...50 Bare Boiler Assembly ...

Page 52: ...52 Bare Boiler Assembly ...

Page 54: ...54 Jacket Assembly ...

Page 56: ...56 MPO84 Thru MPO231 Water Boilers Trim and Controls ...

Page 58: ...58 Beckett AFG Burner ...

Page 61: ...61 Figure A2 LWCO Location ...