15

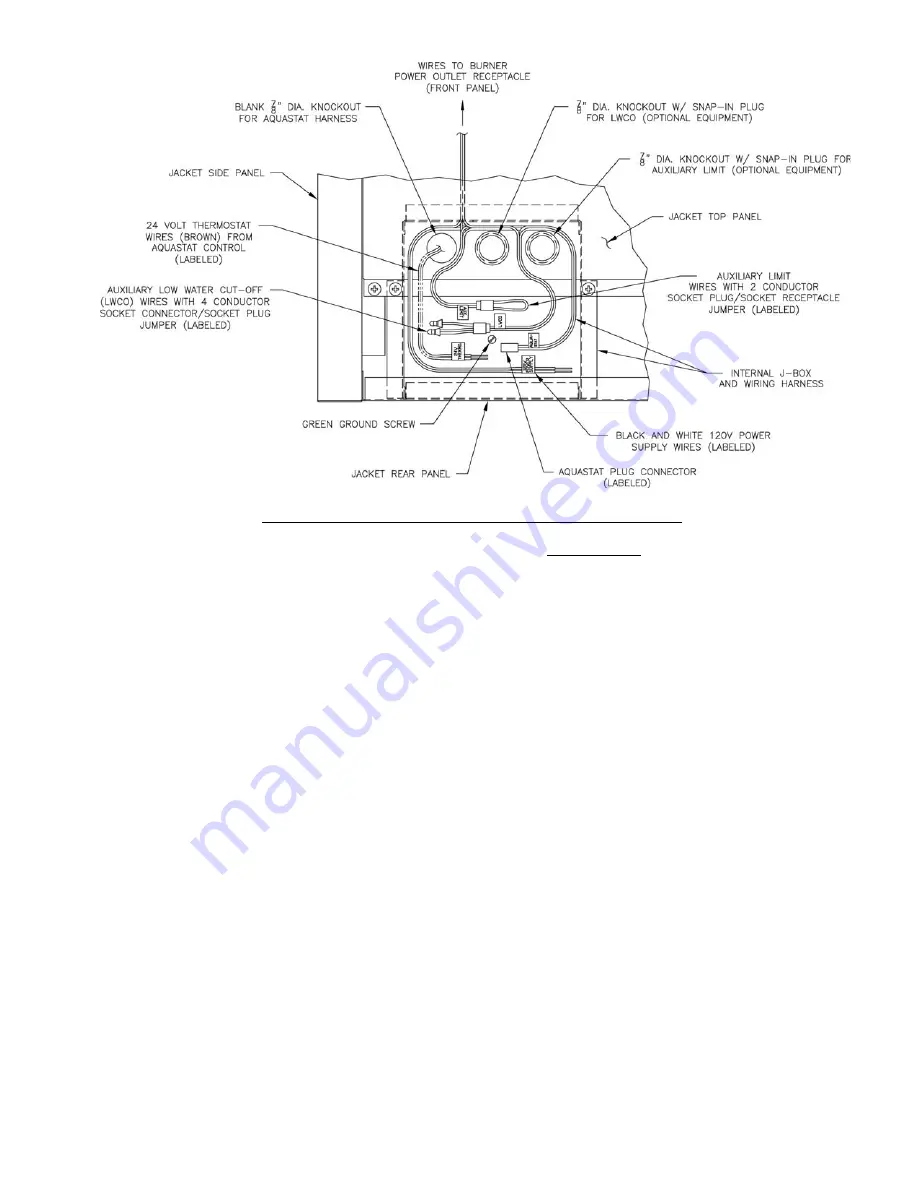

Figure 6: Internal Junction Box and Wiring Harness Details

Mount the control box on the probe by aligning

the keyhole slots with the probe mounting

screws. Replace the wing nut. Secure the

control box by tightening wing nut and two (2)

mounting screws.

Step c.

Remove snap-in plug from 7/8" dia. center

knockout, adjacent to aquastat control harness.

Step d.

Insert three (3) wires with Molex connector

located on opposite end of LWCO harness

through 7/8" dia. knockout. Fish wires with

Molex connector to rear of internal junction box.

Insert snap-in conduit connector into 7/8" dia.

knockout, squeeze tabs on side of connector,

push into knockout and release tabs to lock

connector in place.

Step e.

Inside internal junction box, locate wires

with mating LWCO socket connector labeled

"LWCO" (refer to Figure 6 for details of harness

located inside internal junction box). Remove

the factory installed socket plug jumper from

LWCO harness socket connector and discard.

Align mating halves of plug connector from

LWCO control with harness socket connector.

Push connectors together until snap on side of

connector is locked in place.

3. If required on this water boiler application,

install Auxiliary Dual Limit Control Kit, optional

equipment - Burnham P/N 100107-01, refer to

Figure 8. Also refer to instructions provided with

Auxiliary Dual Limit Control Kit.

If not required

, proceed to Paragraph 4.

Step a.

Locate 1/2" NPT x 1-1/2 immersion well.

Apply thread sealant to 1/2" NPT male threads.

Thread well into 1/2" NPT boss on left side of

supply manifold. Using hex head, tighten well

until water tight.

Step b.

Locate L4080B Auxiliary Limit Control/

Harness Assembly. Loosen mounting screw on

side of case. Insert sensing bulb into immersion

well. Mount control on immersion well and

tighten screw to secure control in vertical

position with harness extending toward rear as

shown in Figure 8.

Step c.

Remove snap-in plug from 7/8" dia.

knockout closest to supply manifold. Remove

locking ring from 90° conduit connector on end

of control harness.

Step d.

Insert two (2) wires with Molex connector

located on end of auxiliary limit control harness

through 7/8" dia. knockout. Fish wires with

Molex connector to rear of internal junction

box. Insert 90° conduit connector into 7/8" dia.

knockout, secure to top panel with locking ring.

Step e.

Inside internal junction box, locate wires

with mating auxiliary limit socket connector

labeled "Aux. Limit" (refer to Figure 6 for

details of harness located inside internal junction

box). Remove the factory installed socket plug

jumper from harness socket connector and

discard. Align mating halves of plug connector

Summary of Contents for MPO Series

Page 6: ...6 Figure 1 MPO 84 Thru MPO 231 Water Boiler ...

Page 22: ...22 Figure 13A Water Boiler Piping for Circulator Zoned Heating System Supply Side Circulator ...

Page 38: ...38 Figure 27 L1 L2 and V1 Head Electrode Positioning and Gun Setting Beckett AFG ...

Page 49: ...49 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 50: ...50 Bare Boiler Assembly ...

Page 52: ...52 Bare Boiler Assembly ...

Page 54: ...54 Jacket Assembly ...

Page 56: ...56 MPO84 Thru MPO231 Water Boilers Trim and Controls ...

Page 58: ...58 Beckett AFG Burner ...

Page 61: ...61 Figure A2 LWCO Location ...