18

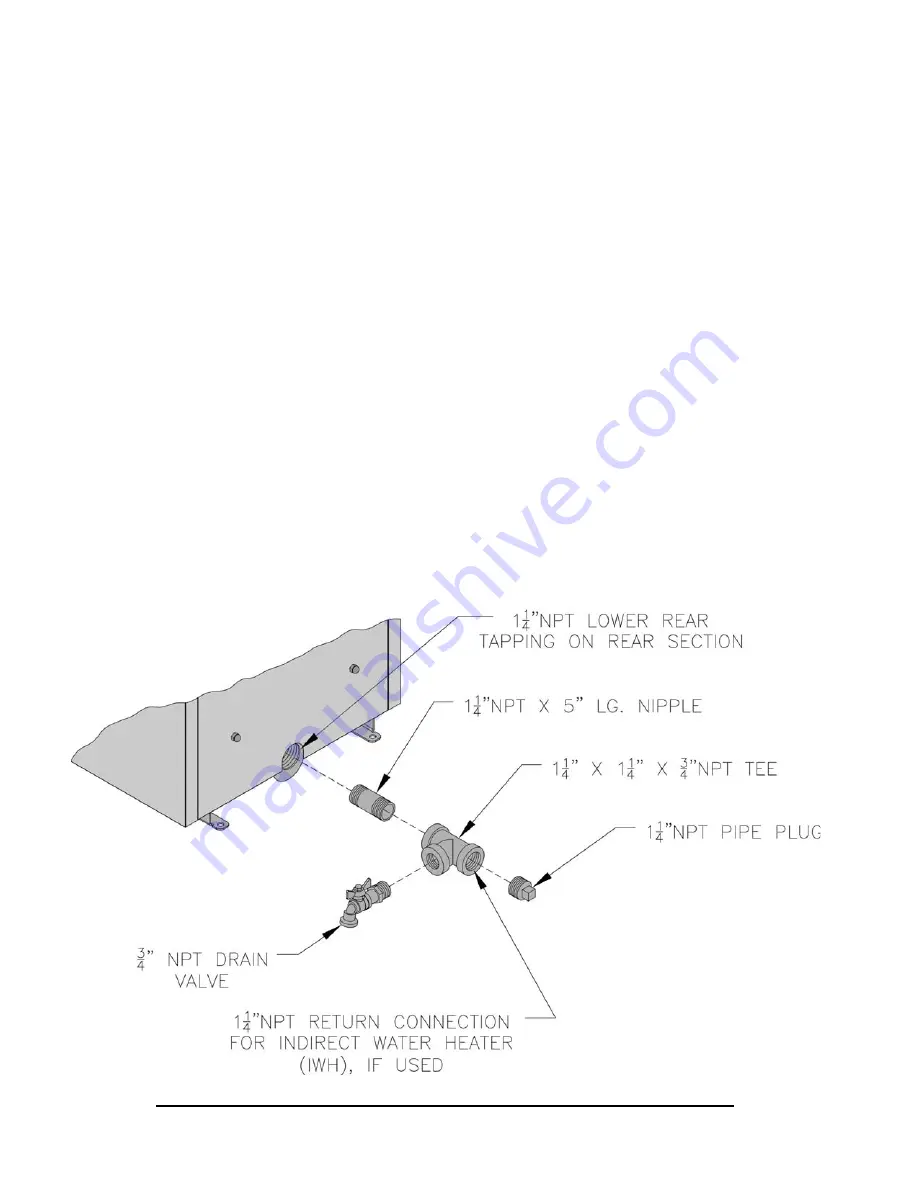

these fi ttings, determine if drain valve is to be

located on the left or right side.

Tighten nipple and tee into 1-1/4" NPT lower

rear tapping on rear section until joints are water

tight for desired position.

Step c.

Apply sealant to 3/4" NPT thread on drain

valve. Thread into 3/4" NPT tapping on side

outlet of tee. Use hex nut portion to tighten

valve until water tight.

Step d.

If Alliance ™ Indirect Water Heater is

connected to system, do not install 1-1/4" NPT

pipe plug. Connect piping as shown in Figures

13A, 13B, 15A and 15B, as applicable. Also

refer to Alliance ™ manual for additional

information.

6. Connecting fi eld wiring, refer to Figures 5, 6 and 19.

Step a.

120 volt power supply fi eld wiring will

enter internal junction box through 7/8" dia.

knockout in jacket rear panel, see Figure 5.

Step b.

Locate the black and white harness wires

labeled "120V Power Supply" inside internal

junction box, see Figure 6. Using wire nuts,

connect the 120 volt power supply fi eld wires to

the harness wires. Connect the fi eld ground wire

to the green grounding screw located in bottom

of internal junction, refer to Figures 6 and 20.

Step c.

24V thermostat fi eld wiring will enter

internal junction box through 5/16" snap bushing

Figure 10: Piping Arrangement for Drain Valve and Indirect Water Heating Return

located on rear panel adjacent to 7/8" dia.

knockout for power supply.

Step d.

Locate the two (2) brown wires labeled

"24V Thermostat" inside the internal junction

box, see Figure 6 (these wires originate from

"T-T" terminals in aquastat control and feed

into J-box through harness). Using wire nuts,

connect 24 volt fi eld thermostat wires to brown

wires in J-box.

Step e.

Locate jacket top rear panel that was

removed earlier to gain access to internal

junction box. Position panel between side

panels, hold on a slight angle, engage tabs on

front fl ange of

top rear

panel with rectangle

slots on rear fl ange of

top

panel, refer to Figures

5 and 9.

NOTE:

It may be necessary to lift up slightly

on

top

panel near slotted opening at supply

manifold to align tabs with rectangular slots on

fl anges.

Lower

rear

fl ange of jacket

top rear

panel down

over

rear

panel. Align holes and secure with

two (2) #8 x 1/2" lg. sheet metal screws.

7. Installing stainless steel fl ueway baffl es. Baffl e

requirements differ from model to model, see

Table 2.

NOTE:

Read caution statement

before

proceeding.

Summary of Contents for MPO Series

Page 6: ...6 Figure 1 MPO 84 Thru MPO 231 Water Boiler ...

Page 22: ...22 Figure 13A Water Boiler Piping for Circulator Zoned Heating System Supply Side Circulator ...

Page 38: ...38 Figure 27 L1 L2 and V1 Head Electrode Positioning and Gun Setting Beckett AFG ...

Page 49: ...49 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 50: ...50 Bare Boiler Assembly ...

Page 52: ...52 Bare Boiler Assembly ...

Page 54: ...54 Jacket Assembly ...

Page 56: ...56 MPO84 Thru MPO231 Water Boilers Trim and Controls ...

Page 58: ...58 Beckett AFG Burner ...

Page 61: ...61 Figure A2 LWCO Location ...