60

B. MPO LWCO

To simplify installation, the MPO LWCO can be

easily installed by removing the LWCO jumper

inside the internal junction box and connecting the

harness into the boiler Molex plug.

Refer to Section II, Paragraph F, Item 2 (of this

manual) for more details.

How to Test

Shut off fuel supply. Lower water level until water

level is BELOW the LWCO. Generate a boiler demand

by turning up thermostat. Boiler should not attempt to

operate. Increase the water level by fi lling the system.

The boiler should attempt to operate once the water

level is above the LWCO.

G

N

I

N

R

A

W

.

)

O

C

W

L

(

f

f

O

t

u

C

r

e

t

a

W

w

o

L

t

e

k

r

a

m

r

e

t

f

a

n

a

l

l

a

t

s

n

i

o

t

s

e

r

i

w

y

r

o

t

c

a

f

t

u

c

o

t

T

P

M

E

T

T

A

T

O

N

O

D

.

f

f

O

t

u

C

r

e

t

a

W

w

o

L

r

o

f

d

e

i

f

i

t

n

e

d

i

y

l

l

a

c

i

f

i

c

e

p

s

s

n

o

i

t

c

e

n

n

o

c

e

s

u

y

l

n

O

.

s

n

o

i

t

c

u

r

t

s

n

i

s

'

r

e

r

u

t

c

a

f

u

n

a

m

)

O

C

W

L

(

f

f

O

t

u

C

r

e

t

a

W

w

o

L

e

h

t

w

o

l

l

o

f

,

s

e

s

a

c

l

l

a

n

I

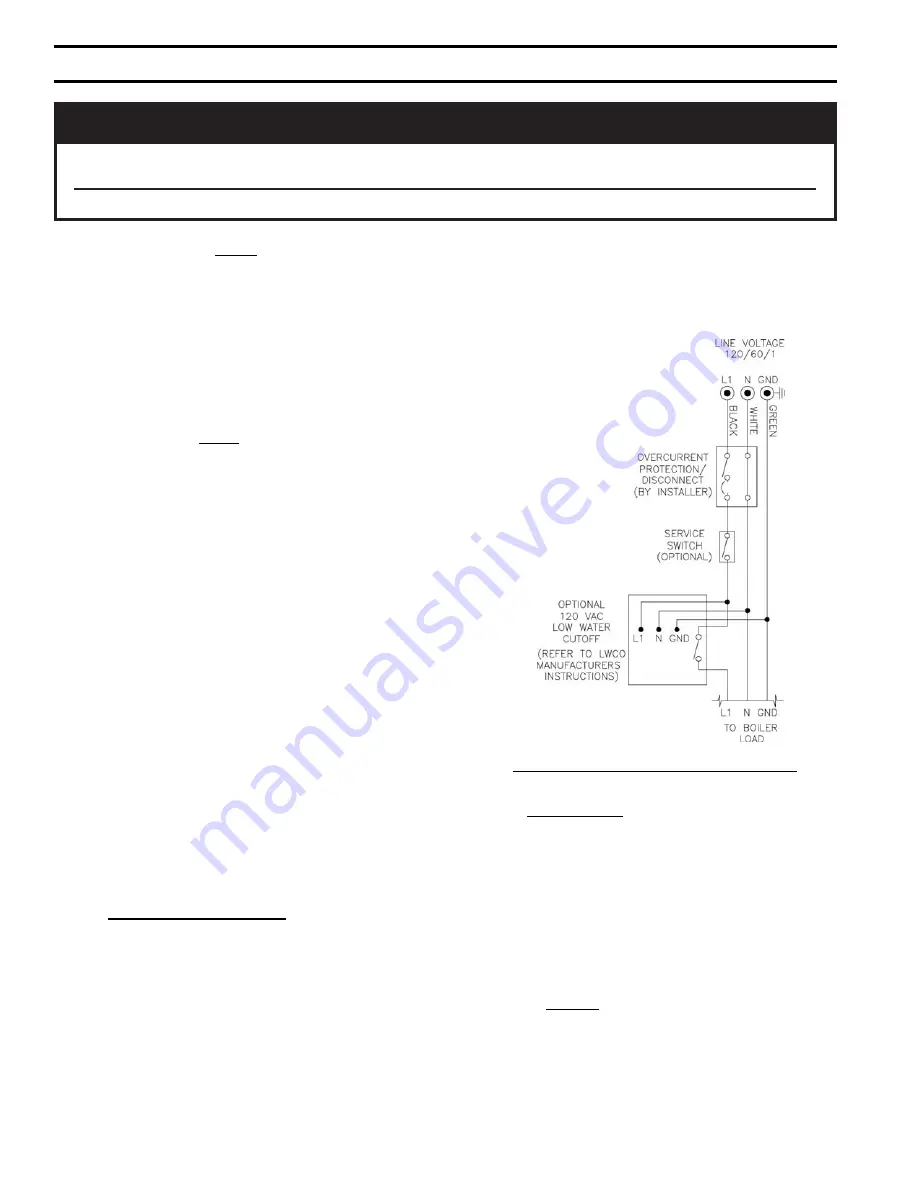

XIV. LOW WATER CUT-OFF (LWCO) ON HOT WATER BOILERS

Figure A1: Wiring of Aftermarket LWCO

When

A low water cut-off is required to protect a hot water

boiler when any connected heat distributor (radiation)

is installed below the top of the hot water boiler (i.e.

baseboard on the same fl oor level as the boiler). In

addition, some jurisdictions require the use of a LWCO

with every hot water boiler.

Where

The universal location for a LWCO on both gas and oil

hot water boilers is above the boiler, in either the supply

or return piping. The minimum safe water level of a

water boiler is at the uppermost top of the boiler; that

is, it must be full of water to operate safely. Provisions

have been made on the MPO supply manifold for a

LWCO.

What Kind

Typically, in residential applications, a probe type

LWCO is used instead of a fl oat type, due to their

relative costs and the simplicity of piping for a probe

LWCO.

How to Pipe

Attach the LWCO to the 3/4" NPT connection on the

supply manifold. See Figure A2 for more details.

Ideally, manual shutoff valves should be located

above the LWCO and the boiler to allow for servicing.

This will allow probe removal for inspection without

draining the heating system. Many probe LWCO

manufacturers recommend an annual inspection of the

probe.

How to Wire

A. AFTERMARKET

LWCO

The 120 VAC confi guration can be universally

applied to both gas and oil boilers by wiring it in

the line voltage service to the boiler (after the

service switch, if so equipped).

The presence of water in a properly installed

LWCO will cause the normally open contact of the

LWCO to close, thus providing continuity of the

120 VAC service to the boiler.

It is recommended to supply power to the probe

LWCO with the same line voltage boiler service as

shown in Figure A1. See Figure 20 (of this manual)

for more details.

Summary of Contents for MPO Series

Page 6: ...6 Figure 1 MPO 84 Thru MPO 231 Water Boiler ...

Page 22: ...22 Figure 13A Water Boiler Piping for Circulator Zoned Heating System Supply Side Circulator ...

Page 38: ...38 Figure 27 L1 L2 and V1 Head Electrode Positioning and Gun Setting Beckett AFG ...

Page 49: ...49 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 50: ...50 Bare Boiler Assembly ...

Page 52: ...52 Bare Boiler Assembly ...

Page 54: ...54 Jacket Assembly ...

Page 56: ...56 MPO84 Thru MPO231 Water Boilers Trim and Controls ...

Page 58: ...58 Beckett AFG Burner ...

Page 61: ...61 Figure A2 LWCO Location ...