Summary of Contents for operating and

Page 2: ...2 ...

Page 8: ...8 Section I General Information Figure 1 Dimensional Information ...

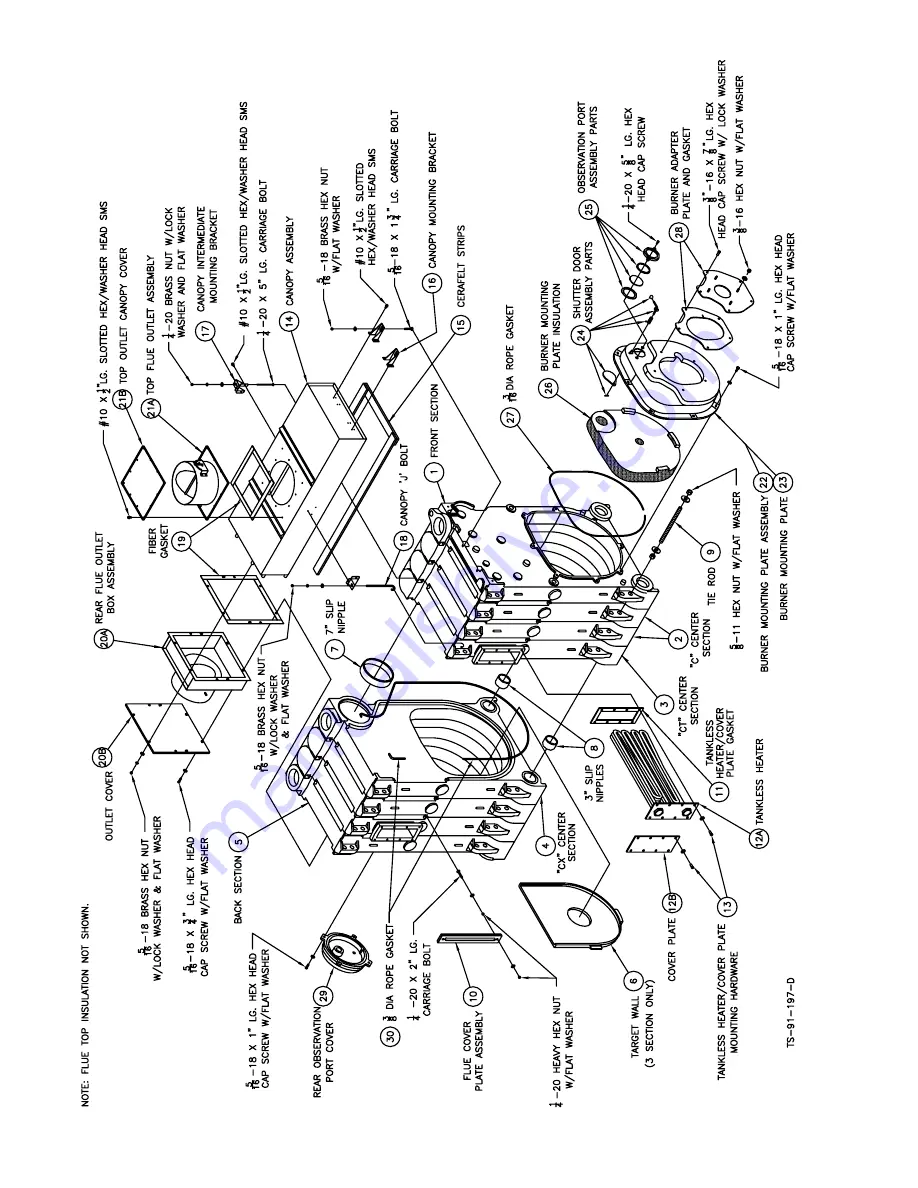

Page 21: ...21 Figure 16 Bare Boiler Assembly ...

Page 25: ...25 Figure 22 V9A Series Jacket Assembly Boiler Models V903A thru V912A ...

Page 31: ...31 Figure 26 V9A Series Minimum Piping Parallel Water Boiler ...

Page 32: ...32 Figure 27 V9A Series Minimum Piping Primary Secondary Water Boiler ...

Page 33: ...33 Figure 28 V9A Series Minimum Piping Details Bypass with Blend Pump Water Boiler ...

Page 34: ...34 Figure 29 V9A Series Minimum Piping Primary Secondary with Bypass Water Boiler ...

Page 37: ...37 Figure 32 Minimum Piping Requirements For Gravity Return V9A Series Steam Boilers ...

Page 42: ...42 Figure 37b DHW Generation with Tankless Coils Storage Tank and Destratification Pump ...

Page 43: ...43 Figure 37c DHW Generation with Indirect Water Heater ...

Page 58: ...58 Figure 40 Bare Boiler Assembly ...

Page 62: ...62 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 63: ...63 SERVICE RECORD DATE SERVICE PERFORMED ...

Page 64: ...64 ...