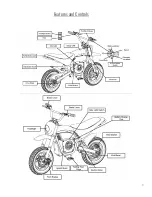

13

REPAIR AND MAINTENANCE

Warning: Turn power switch “OFF” before conducting any

maintenance procedures.

Servicing the Brake

The TT1600R is equipped with Hydraulic brake systems front and

rear. Hydraulic disc brake pads are also self-adjusting for wear, so

if the lever is being pulled back too far,or is hitting the handlebar

the hydraulic system needs to be put through the proper bleeding

process to remove air bubbles. You also need to check for leaks,

loss of fluid, and check the wear on the brake pads. If you are

unfamiliar with hydraulic brakes you may find it better to have a

good bike repair shop do the inspection and bleed process as it

requires a special kit, replacement fluid, and has to be carried out

following proper procedure.

Inspecting and replacing the brake pads:

Burromax stocks replacement brake pads and they are relatively

easy to replace.

It’s important to check the pads regularly – if they

wear out right down to the backing plate, metal-on-metal contact

will destroy brake rotors very quickly.

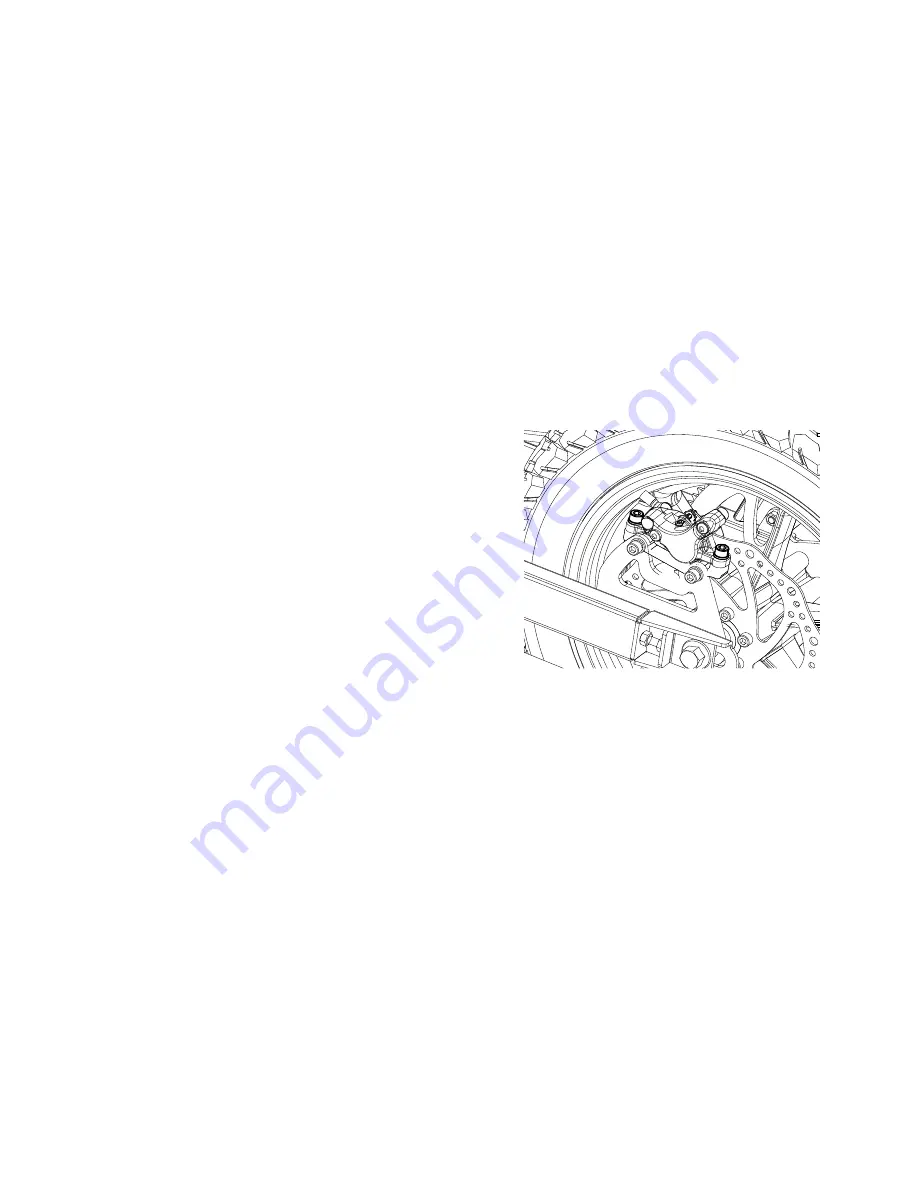

If you need to replace the brake pads, start by removing the caliper

from the brake mounting bracket. Then Push the old pads into the

caliper with a pad pusher tool or a large flat head screwdriver.

Insert the tool in between the two brake pads and Twist or pry. This

action will push the brake pistons back into the caliper. Remove the

split retaining pin holding the brake pads in place. Remove the pads

and spring using needle-nose pliers. At this point it’s a good idea to

clean the inside of the caliper and rotor with a little degreaser and

paper cloth, to remove any brake dust or dirt build-up. Install the

new pads along with the retention pins and spring clip.

If you need to replace the brake disc, now is time to remove the

wheel and replace it. When reinstalling the wheel make sure that

you reinstall the spacer in the correct locations and the wheel rolls

freely after the axle has been properly tightened.

Install the caliper over the Brake Rotor, align the mounting holes

and install the mounting bolts. Before tightening the mounting bolts

Loosen the caliper adjusting bolts one full turn so that the caliper is

loose on the mounting bracket. Finish tightening and

Check all brake mounting bolts.

You might have to squeeze the

lever several times before the pads engage. If they don’t grip the

rotor after repeated pumps then you will need to bleed the brakes.

Squeeze the brake lever a couple more times to set the position of

the caliper. Squeeze the brake lever one more time and hold

pressure on the lever while tightening the caliper adjusting bolts.

This will align the caliper and brake pads. The rotor should be

running parallel and central to the caliper body. When depressed

the brake lever should be approximately 1 inch or more off the hand

grip and have a firm feel

The wheel should roll freely without dragging on the brake when

this operation is completed.

Testing the Brakes

To test the brake, squeeze the lever to increase the pressure on the

brake. When depressed The brake lever should be approximately 1

inch or more off the hand grip and have a firm feel. The wheel

should roll freely by hand when the brake is not applied and the

brake should lock up when applied with force.

WARNING:The brakes can cause the electric motorbike to skid the

tire throwing an unsuspecting rider. Practice in an open area free

from obstacles until you are familiar with the brake function. Avoid

skidding to a stop as this can cause you to lose control.

Note: Brakes that are poorly adjusted can be draggy and will cause

excessive wear and poor performance.