8224 2462-001

16

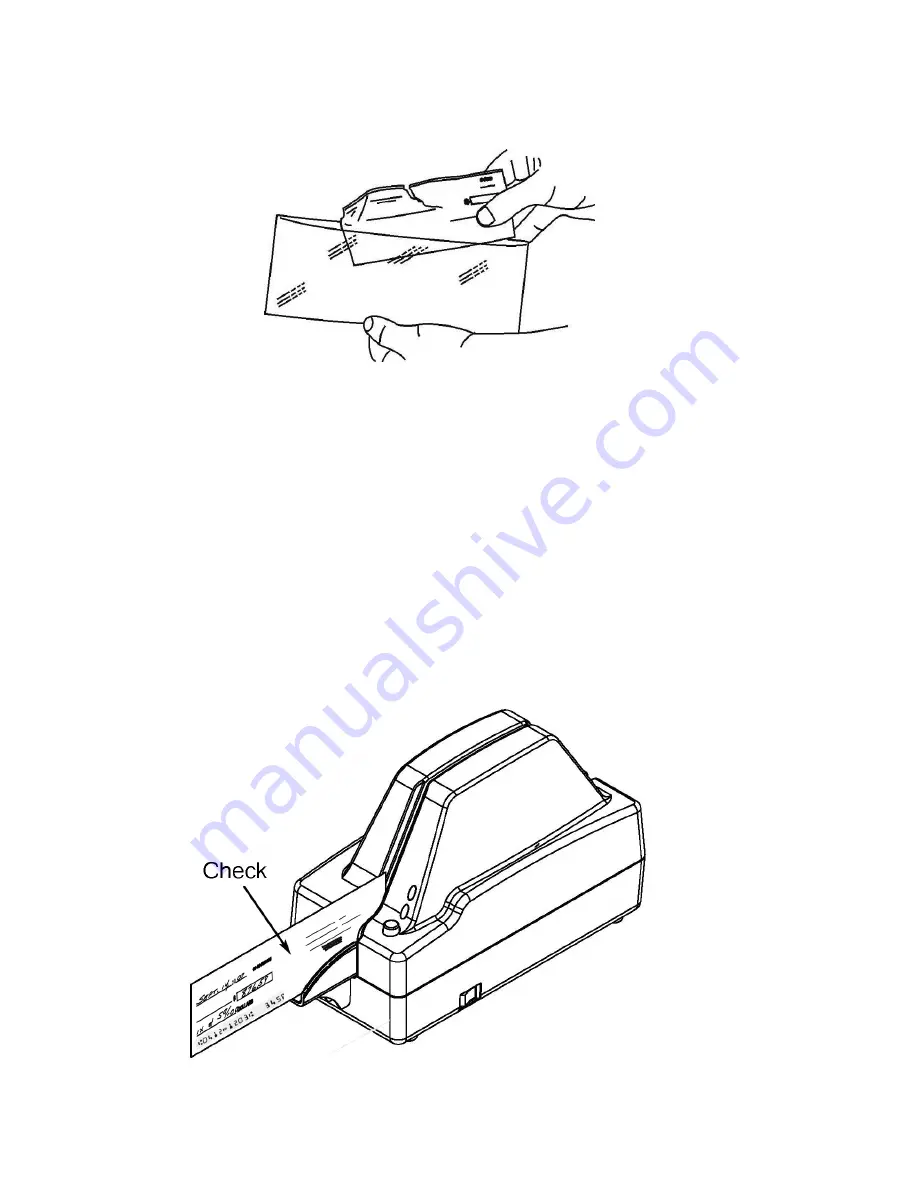

Repair torn or damaged paper, or place each damaged item into a carrier envelope.

−Do not use tape to repair areas with code line or encoded amount information.

Feeding Checks

Insert the check into the feeder when status indicator is off. Place the check so that the

MICR characters are toward the feed button. Only one check can be inserted and fed

per pass.

Note: To prevent image skewing, the bottom edge of check should contact the

bottom edge of the feeder extender.

The SmartSource Edge will start scanning when it detects that there is a check present.

Remove the check after it has been processed.

Another check may now be processed in the same manner.

Summary of Contents for SmartSource Edge

Page 4: ...8224 2462 001 4 Reader 32 Image 33 Parts 33...

Page 6: ...8224 2462 001 6 Unpack the Box Like This...

Page 7: ...8224 2462 001 7 Box Contents...

Page 8: ...8224 2462 001 8 SmartSource Edge Need Help Burroughs Help Desk 1 800 328 0440...

Page 11: ...8224 2462 001 11 Step2 Step3...

Page 13: ...8224 2462 001 13 Section 2 Operating the Unit Power On and Off...