burster Italia s.r.l. · Sede legale ed operativa · Via Cesare Battisti, 16/18 · 24035 Curno (BG) · Tel. +39 035 618120 · Fax +39 035 618250

e-mail: info@burster.it · http://www.burster.it

C.F. e P.IVA 11048400151 · Capitale sociale Euro 49.920,00 · R.E.A. di Bergamo 276749

Apparecchi di misura di precisione. Sensori e Sistemi

per grandezze elettriche, termiche e meccaniche

4.3

Basic Assembly

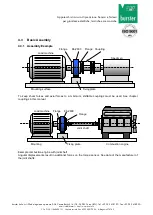

4.3.1 Assembly Example

To keep shear forces and axial forces to a minimum, shiftable couplings must be used. See chapter

couplings in this manual.

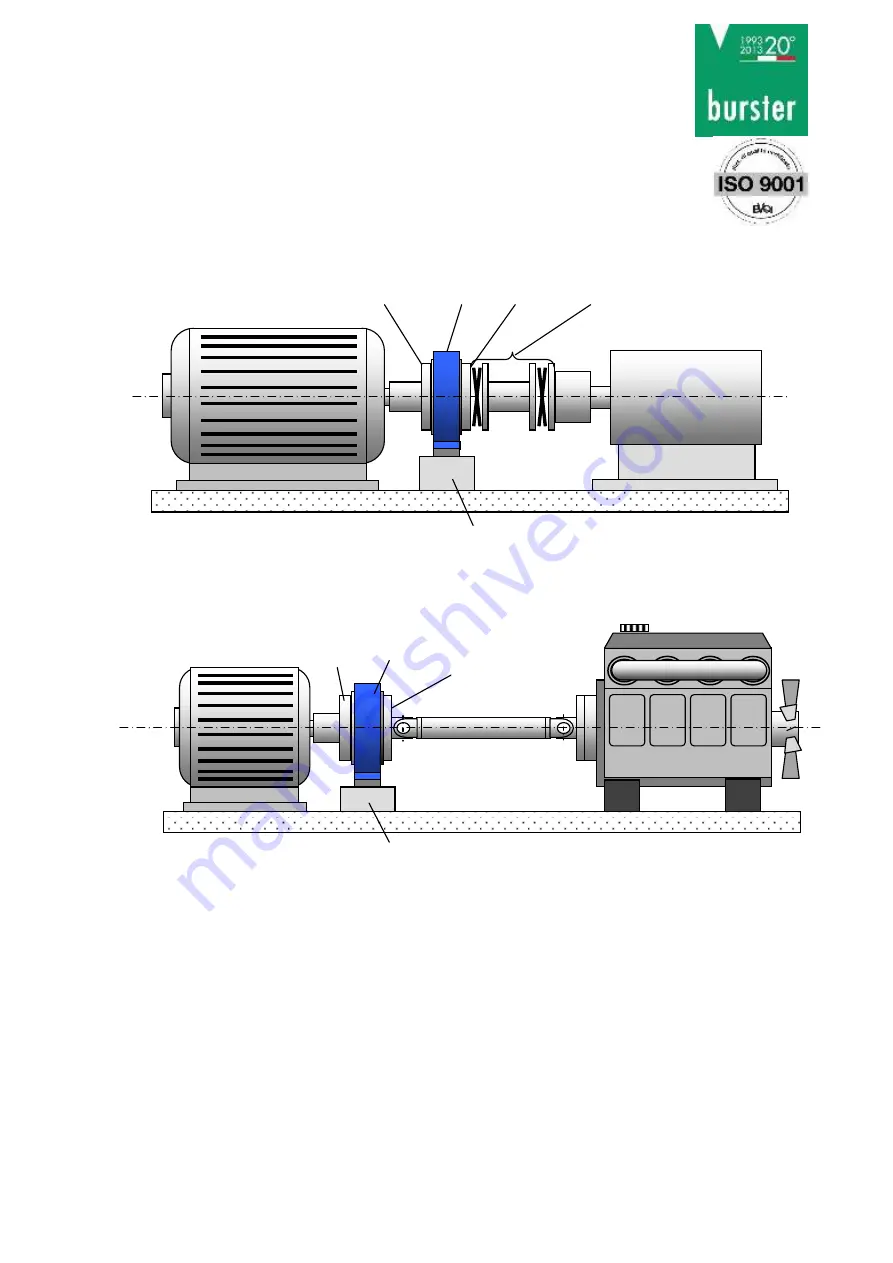

Example combustion engine with joint shaft

Angular displacements result in additional forces on the torque sensor. See data of the manufacturer of

the joint shafts.

86-2800 Flange Coupling

Specimen

Load machine

Mounting surface

Fixing plate

Load machine

86-2800

Combustion engine

Mounting

surface

Fixing plate

Joint shaft

Flange

Flange

Flange