burster Italia s.r.l. · Sede legale ed operativa · Via Cesare Battisti, 16/18 · 24035 Curno (BG) · Tel. +39 035 618120 · Fax +39 035 618250

e-mail: info@burster.it · http://www.burster.it

C.F. e P.IVA 11048400151 · Capitale sociale Euro 49.920,00 · R.E.A. di Bergamo 276749

Apparecchi di misura di precisione. Sensori e Sistemi

per grandezze elettriche, termiche e meccaniche

Zero point outside of tolerance

Cable defect

Repair cable

Shaft mounted distorted

Mount correctly

Distorted shaft string

Release distortion

Strong lateral forces

Reduce lateral forces

Distorted flanges

Check evenness of flange-

surfaces

Shaft overloaded

Send to manufacturer

Wrong torque indication

Calibration not correct

Re-calibrate

Sensor defect

Repair by manufacturer

Torque shunt

Eliminate shunt

Shaft grinds

Shaft grinds in the rotor

Align shaft

Concentricity of the parts is not

ensured

Lateral forces too large

Decrease lateral forces

Oscillations

Alignment of shaft not correct

Align correctly

Unbalance

Balance the corresponding parts

8

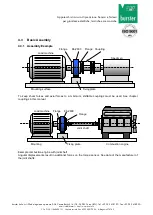

Decommissioning

All sensors must be dismantled professionally. Couplings may not be damaged. Do not strike sensor

housings with tools. Do not exert punches on the sensor with a tool. Do not apply bending moments on

the sensor, e.g. through levers. The torque sensor must be supported to avoid falling down during the

dismantling.

9

Transportation and Storage

The transportation of the sensors must occur in suitable packing. The sensor should be wrapped in foil,

so no packing material can get into the device. Larger sensors should be packed in boxes. Use the

supplied fixing plates for storage or transportation of the sensor.

9.1

Transportation

Only release well packed sensors for transportation. The sensor should not be able to reciprocate in the

packing. The sensor must be protected from moisture.

Use only suitable means of transportation.

9.2

Storage

The storage of the sensors must occur in dry, dust-free rooms, only.

Lightly oil shafts and flanges before storing (rust).

10

Disposal

The torque sensors must be disposed in accordance with applicable legislation.

11

Calibration

At the time of delivery, torque sensors have been adjusted and tested with traceable calibrated measuring

equipment at factory side. Optionally, a calibration of the sensors can be carried out.