burster Italia s.r.l. · Sede legale ed operativa · Via Cesare Battisti, 16/18 · 24035 Curno (BG) · Tel. +39 035 618120 · Fax +39 035 618250

e-mail: info@burster.it · http://www.burster.it

C.F. e P.IVA 11048400151 · Capitale sociale Euro 49.920,00 · R.E.A. di Bergamo 276749

Apparecchi di misura di precisione. Sensori e Sistemi

per grandezze elettriche, termiche e meccaniche

References in this Text

Attention must be paid to the accident prevention regulations of the trade associations.

Coverings and casings are necessary before operating the sensor. This is also valid for

commissioning, maintenance and trouble shooting.

Duties of the coverings and casings are:

Protection from detaching parts

Protection from contusion and shear

Prevention from reaching rotating parts

Prevention from being tangled up and/or getting caught by parts

Coverings may

Not grind

Not rotate

Coverings are also necessary outside of operating and motion travel areas of persons.

These demands can be modified if other sufficient safety devices are available. During

operation, the safety precautions must be operative. Vibrations can cause device

damages. .

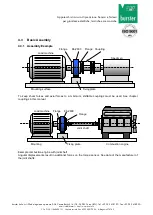

4 Mechanical Assembly; Page 8

Caution:

Inadmissibly large forces may not act on the sensor or the couplings during the

assembly. Connect the sensor electrically during the assembly and observe the signal, the

measurement signal may not exceed the limit values

To avoid falling down, the sensor must be supported during the assembly.

Admissible assembly offset from rotor to stator:

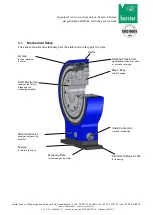

4.2 Stator Assembly

Caution!

At alternating torque, the screws for the flange connections must absolutely be

secured with screw locks.

4.4.1 Alignment of the Measurement Arrangement; Page 12

For details see the manual of the couplings and data sheet of the torque sensor for the

limit thrust load and the limit shear force.

6.1 Engaging; Page 13

The warm-up period of the torque sensor is approx. 5 minutes.

6.4.2 Torsional Natural Resonances; Page 14

Operation of the device in natural resonance can lead to permanent damages.

6.4.3 Bending Natural Resonances; Page 14

Operation of the device in bending natural resonance can lead to permanent damages.