burster Italia s.r.l. · Sede legale ed operativa · Via Cesare Battisti, 16/18 · 24035 Curno (BG) · Tel. +39 035 618120 · Fax +39 035 618250

e-mail: info@burster.it · http://www.burster.it

C.F. e P.IVA 11048400151 · Capitale sociale Euro 49.920,00 · R.E.A. di Bergamo 276749

Apparecchi di misura di precisione. Sensori e Sistemi

per grandezze elettriche, termiche e meccaniche

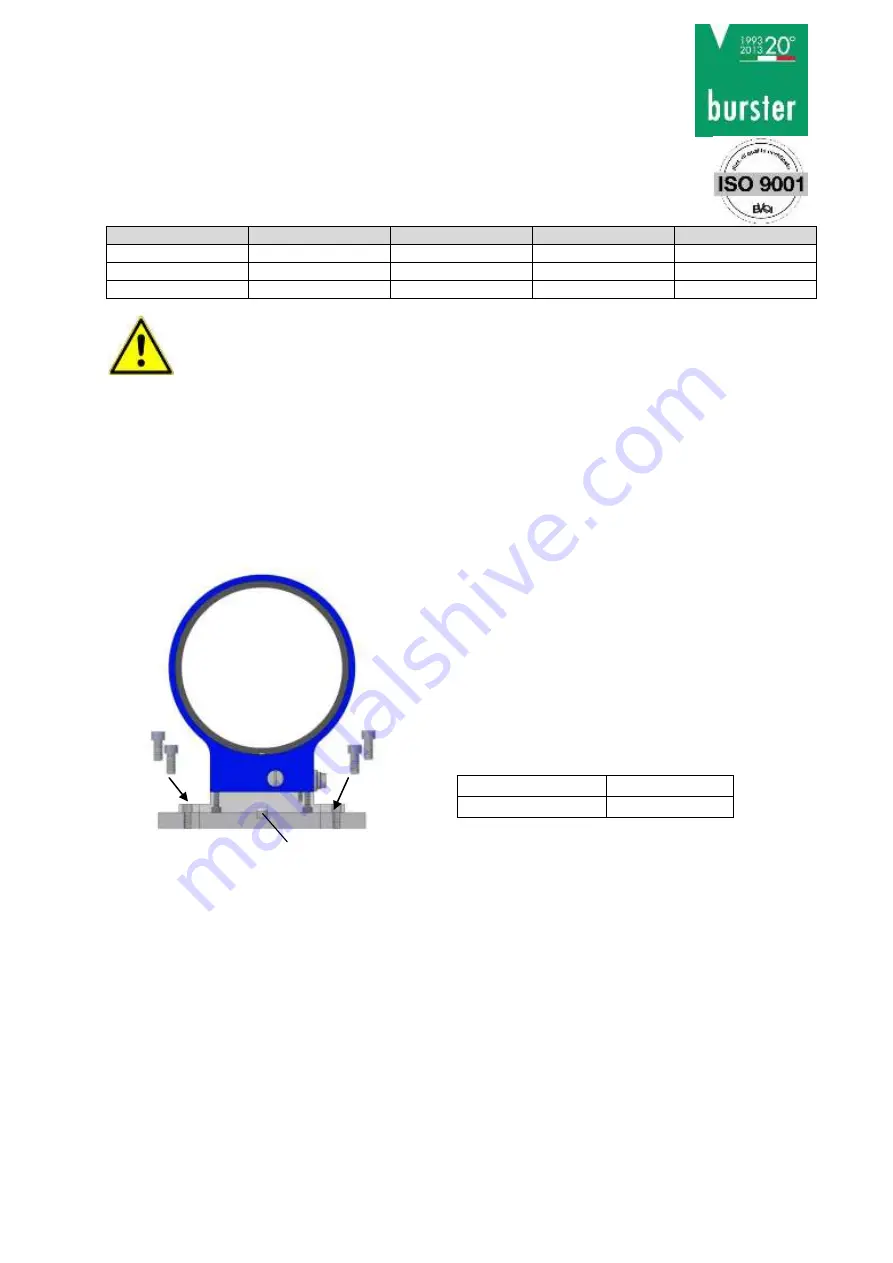

Nominal Torque

Screw

Quantity

Thread depth

Tightening torque

50 / 100 N·m

M 6

8

12 mm

14 N·m

200 N·m

M 8

8

12 mm

35 N·m

500 / 1000 N·m

M12

8

12 mm

120 N·m

Caution!

At alternating torque, the flange connection screws must absolutely be secured with

screw locks. Otherwise the connection screws may loosen.

The used screws may not be too long:

Shunt of the torque measurement

Flange connection is not twist-protected

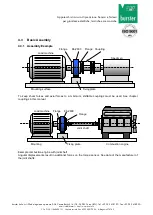

Then remove the 3 fixing plates and control the position of shaft to stator:

a) Axial alignment of the shaft

b) Evenness of the air gap (shaft may not grind at the stator)

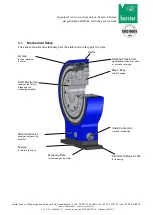

4.2

Stator Assembly

Use keyway for the axial alignment

Align stator to shaft

Rotor may not touch the stator

Note the axial position of rotor to stator

Tolerance: ± 0,5 mm

Tighten screws with a torque wrench.

Use suitable washers, if necessary.

Strength:

8.8

Tightening torque:

24 N·m

2x M8

2x M8

Keyway