MM3156A DRUM SANDER

26

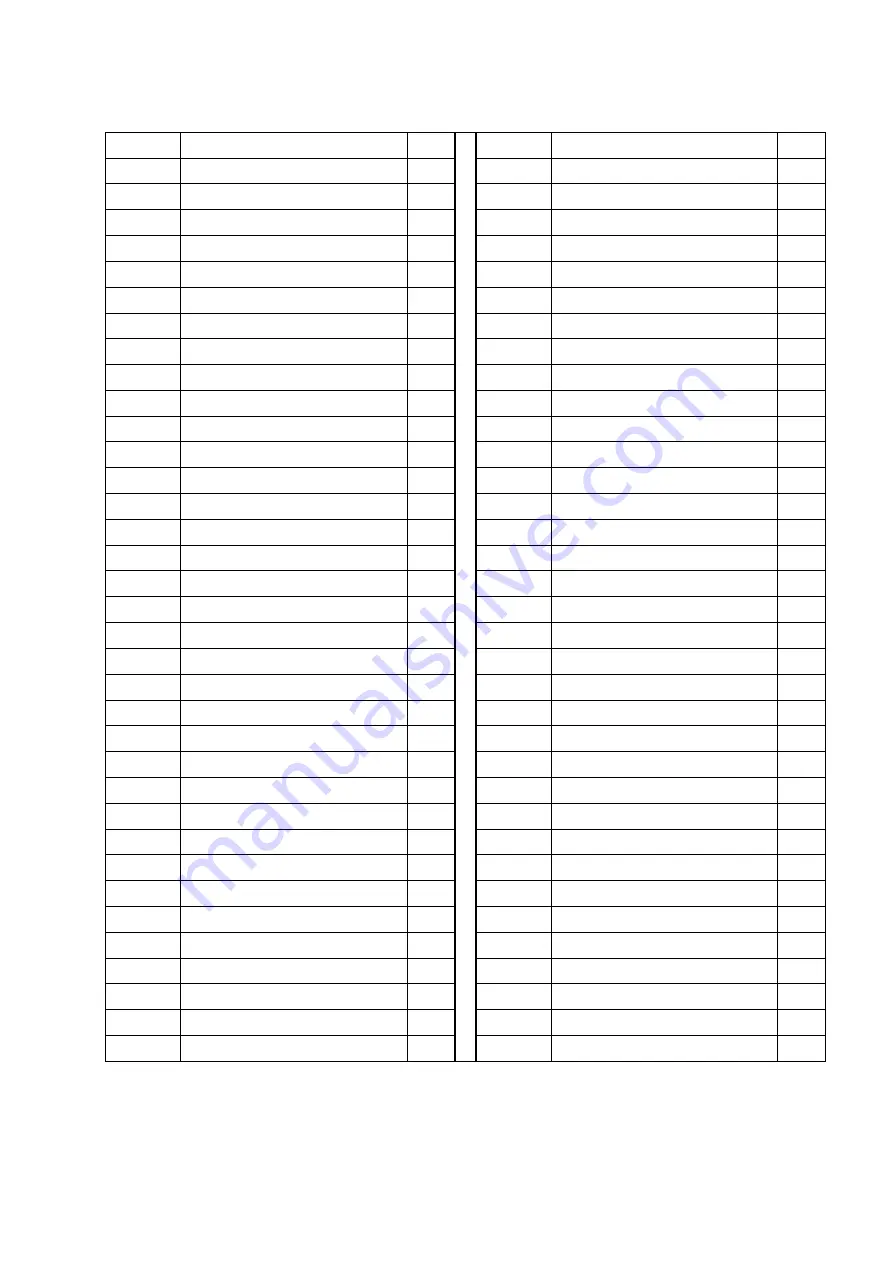

PART LIST FOR MAIN BODY

Number

Description of part

Qty

Number

Description of part

Qty

74

handle

1

100

bridge

1

75

hex-cap bolt M10X35

4

101

samller axle joining

2

76

spring washer

∮

10

4

102

"

十

" flange screw M5X10

2

77

washer

∮

10

8

103

base

1

78

lift base

1

104

transformer

1

80

sucken hex-cap screw M8X30

4

105

"

十

" flange screw M4X10

2

81

motor

1

106

hex cap bolt M6X16

3

82

sucken hex-cap screw M8X45

2

109

switch

1

83

"

十

" flange bolt M6X90

2

110

inching lable

1

84

sliping block

2

111

strain relief

3

85

tension block

2

112

plug cord

1

86

sucken hex-cap screw M5X16

4

113

samller motor

1

87

spring

2

114

outside cover

1

88

nut M5

7

115

dielectric

1

89

transport belt

1

116

"

十

" flange screw M5X6

2

90

outfeed roller

1

117

PV board

1

91

sucken hex-cap bolt M8X12

4

118

washer

∮

8

4

92

table

1

119

washer

∮

8

4

93

support block

1

120

hex cap bolt M8X30

2

94

screw M6X16

4

121

Hex wrench 6

1

95

washer

∮

6

10

122

Hex wrench 5

1

96

spring washer

∮

6

7

123

Open end wrench 11/13

1

97

infeed roller

1

132

hex-cap bolt M10X40

4

98

"

十

" flange screw M5X20

1

99

inside cover

1