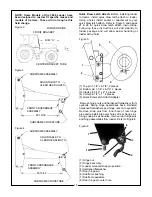

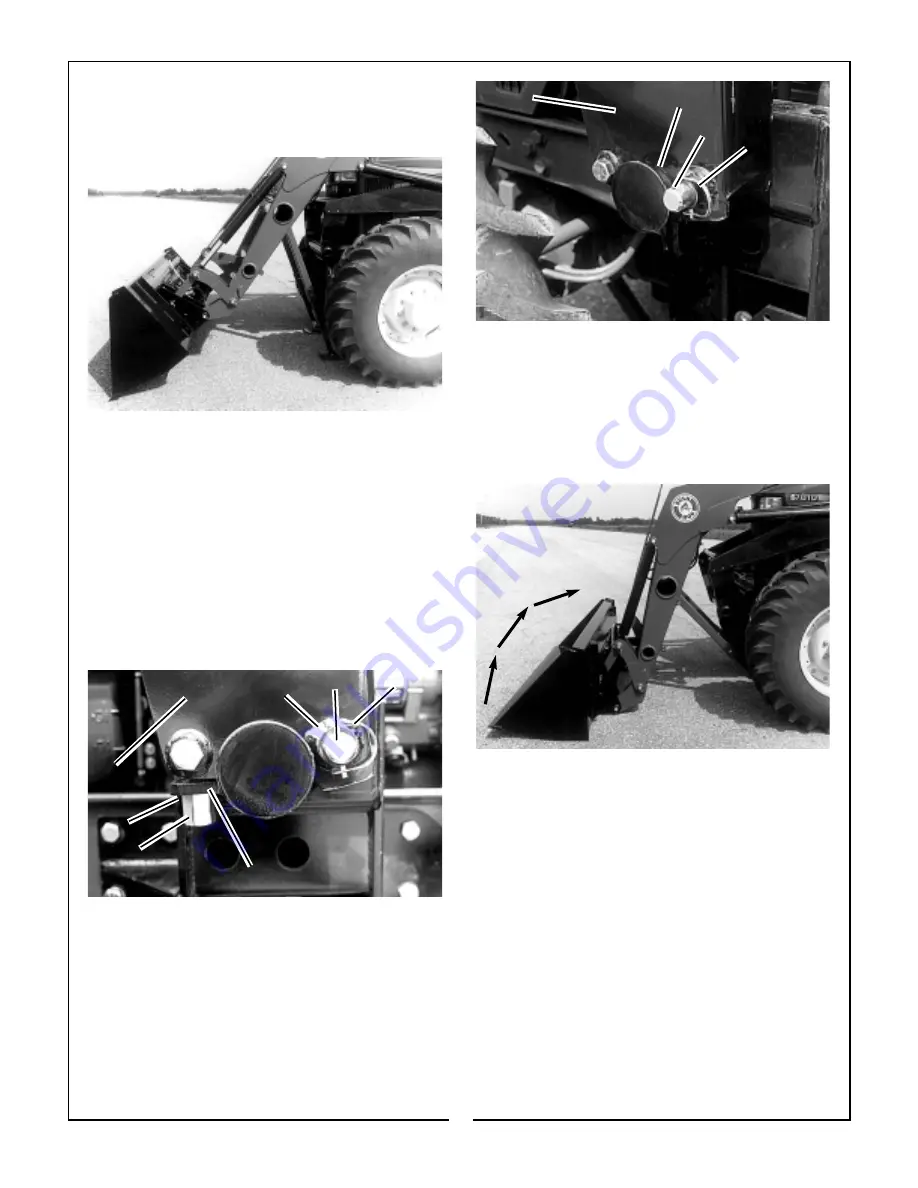

Raise the loader boom and retract the bucket cylin-

ders. Lower the loader boom until the parking stands

make contact with the ground. Dump the bucket until

the bucket touches the ground. Refer to Figure 4.

NOTE: Driving the tractor forward slowly while

positioning loader will allow parking stands to

contact ground firmly. Using float position dur-

ing this operation will keep tractor weight from

being applied to loader parking stands.

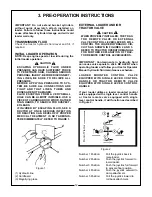

Remove hinge nuts and hardened flatwashers from

eyebolts. Swing hinge assemblies back. Reinstall

hardened flatwashers and hinge nuts onto eyebolts.

Remove snap pins from inner hole of rear hinge pins

and reinstall into outer holes of rear hinge pins.

Using snap pins as handles, remove rear hinge pins

and hinge assemblies from loader. Figures 5 & 6.

Figure 5

(1) Hinge nut.

(2) Hinge assembly.

(3) Loader mounted snap pin position.

(4) Hardened flatwasher.

(5) Rear hinge pin.

(6) Subframe bushing.

(7) Subframe pedestal.

(8) Center mounting bracket tubes. (Figure 6)

(9) Rear hinge pin outer hole. (Figure 6)

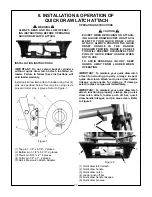

1

4

6

5

3

2

3

9

8

7

Figure 6

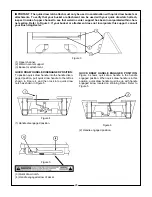

Start the tractor and position the valve control lever

in the float position. Retract the bucket cylinder until

the subframe assembly lifts off of the center bracket

tubes. Take the valve control lever out of the float

position. Back the tractor up approximately one foot.

Make sure hydraulic hoses are not pulled or dam-

aged. Refer to Figure 7.

NOTE: Before backing the tractor away from the

loader, use the lift cylinders to position the sub-

frame crosstube so it moves freely in the front

bracket channel. This will prevent loader move-

ment when backing the tractor away from the

loader.

Make sure the subframe assembly will clear the front

wheels and axle of the tractor. Retract the lift and

attachment cylinders. Stop the tractor engine and

then work valve control lever/levers to relieve

hydraulic fluid pressure in lines. See tractor Operator

Manual for additional information.

Figure 4

Figure 7

24

7