SECTION lV

MAINTENANCE

4-1 MAINTENANCE CHECK LIST

Perform scheduled maintenance as outlined below.

Lower machine to ground, turn off tractor and set

parking brake before doing maintenance inspections

or work. All bolts should be torqued as recommend-

ed in torque chart on inside of back cover unless oth-

erwise indicated.

CAUTION

USE A PIECE OF CARDBOARD OR WOOD RATHER

THAN HANDS AND WEAR EYE PROTECTION WHEN

SEARCHING FOR HYDRAULIC LEAKS. ESCAPING

HYDRAULIC OIL UNDER PRESSURE CAN PENETRATE

SKIN. IF OIL IS INJECTED INTO SKIN, IT MUST BE

SURGICALLY REMOVED WITHIN A FEW HOURS BY A

DOCTOR OR GANGRENE MAY RESULT.

WARNING

THE LOADER CAN FALL FROM HYDRAULIC SYS-

TEM FAILURE. TO AVOID SERIOUS INJURY OR

DEATH, SECURELY SUPPORT LOADER BEFORE

WORKING UNDERNEATH.

BEFORE EACH USE

1. Inspect hydraulic lines and fittings for wear or

leaks. Repair or replace if needed.

2. Inspect all pivot pins for wear. Make certain

cotterpins are installed to retain each pivot pin.

3. Check all bolts for tightness.

4. Perform BEFORE EACH USE lubrication per

paragraph 4-2.

5. During operation, listen for abnormal sounds

which might indicate loose parts or other dam-

age.

AFTER EACH USE

1. Clean all debris from machine.

4-2 LUBRICATION

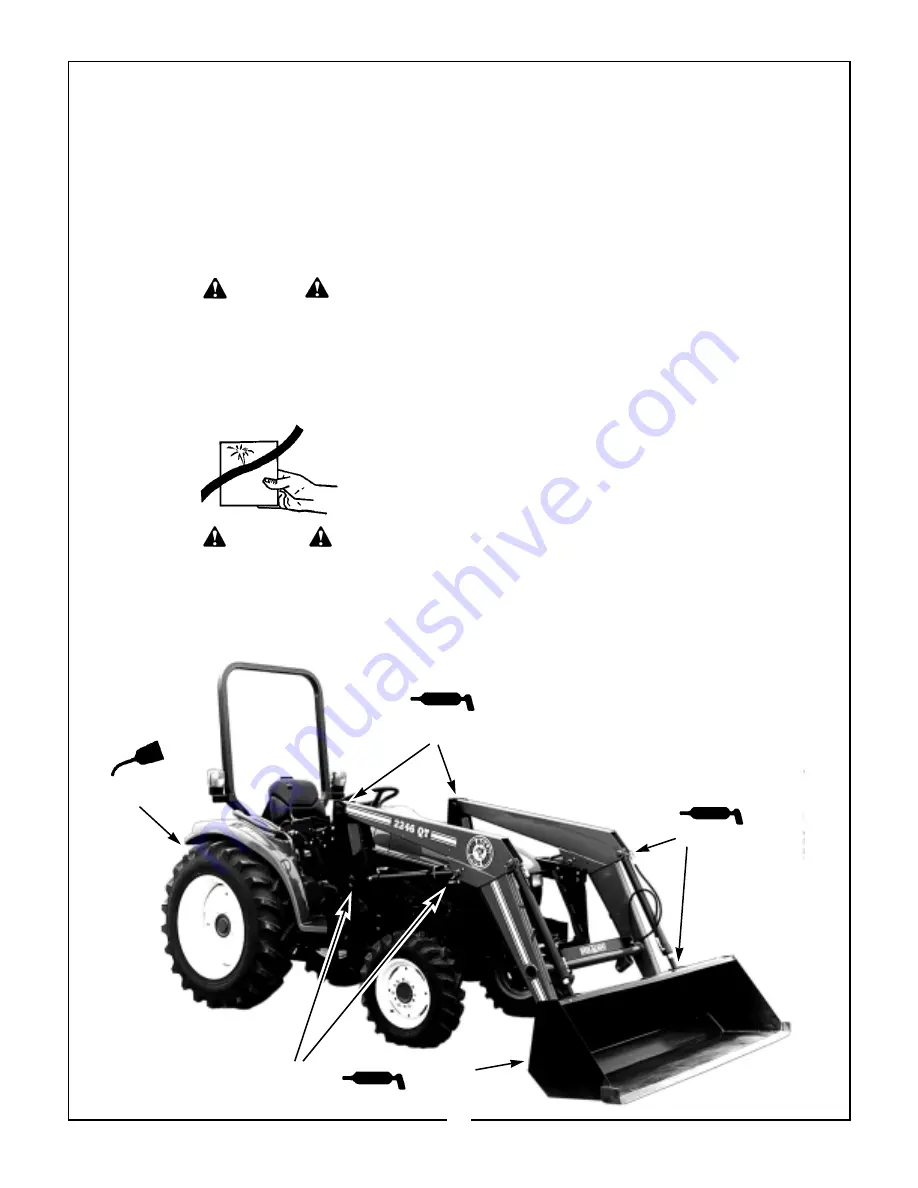

(Figure 4-1)

NOTE

The multipurpose grease referenced in this section

is an NLGI Grade 2 type grease.

BEFORE EACH USE

1. Boom Pivot Pins- Apply multi-purpose grease to

each fitting (1 fitting each side)

2. Boom Cylinders- Apply multi-purpose grease to

each fitting (2 fittings each cylinder)

3. Bucket Cylinders- Apply multi-purpose grease

to each fitting (2 fittings each cylinder)

4. Bucket Pivot Pin- Apply multi-purpose grease to

each fitting (1 fitting each side)

5. Tractor Hydraulic Oil- Cycle boom and bucket

cylinders 2 or 3 times before use then check

tractor hydraulic oil level per tractor operator’s

manual.

Figure 4-1 Lubrication Points

(1) Before

Each Use

(3) Before

Each Use

(5) Before

Each Use

(2) Before

Each Use

(4) Before

Each Use

16