2

2014 RDF 60, 72

Welcome

Thank you for selecting the Bush-Whacker RDF 48, 60, or 70 Finishing

Mower. Your machine has been carefully inspected by both the factory and

the dealership prior to being received by you to ensure that it is ready for

operation.

This manual explains the proper operation of your machine. It is very im-

portant that you read and understand these instructions before operating

or maintaining the machine. Failure to do so could result in personal injury

or even death to you or passersby. Consult your Bush-Whacker dealership

if you do not understand the instructions in this manual or need additional

information.

Hall Manufacturing, Inc. reserves the right to make changes at any time

without notice or obligation. Additional copies of the manuals are available

from your local Bush-Whacker dealer.

Hall Manufacturing, Inc.

3706 E. Washington Ave., P.O. Box Drawer 5638

North Little Rock, AR 72119

Summary of Contents for RDF 48

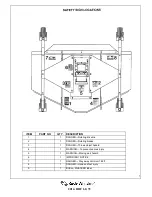

Page 7: ...8 2014 RDF 60 72 Safety Decals ...

Page 8: ...9 2014 RDF 60 72 Safety Decals ...

Page 25: ...26 2014 RDF 60 72 ...

Page 27: ...28 2014 RDF 60 72 RDF 60 General mower assembly ...

Page 29: ...30 2014 RDF 60 72 RDF 72 General mower assembly ...

Page 31: ...32 2014 RDF 60 72 Notes ...

Page 35: ......

Page 37: ......