13

2017 SSM-72

At Least Twice Daily

Rotor Bar Assembly, Blades, Blade Bolts, and Nuts

·

Make sure rotor bar assembly is securely attached with castle nut and cotter pin to the

output shaft. There should be no bearing play when rocking the blade bar.

·

Always make sure to replace the blades in sets.

NOTE: When mowing at low cutting heights or on uneven terrain, the blades can come in

contact with the ground frequently. When this happens, the blade tips can be pushed upwards

causing the blade to bend. By pushing upwards on the blade tip, the rear of the blade (at the

bolt hole) is forced downward away from the rotor bar assembly. This causes the bolt to be

pulled through the bar and can cause it to shear. When the bolt shears, it will throw a blade.

When operating in these conditions, the operator must check the blade bolts more frequently

than normal, at least four times a day.

Always use genuine Bush-Whacker replacement blades, bolts, and nuts. Other blades may not

meet Hall Manufacturing specifications and could lead to serious injury or death.

Daily

Shields

·

Make sure ALL shields are in place and tightened before operating the mower. If one

works loose, stop mowing and tighten immediately.

·

Replace shields if there is any damage or excessive wear.

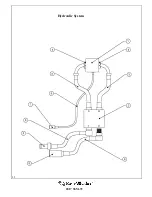

Hydraulics

·

Inspect the Hydraulic Shields, making sure that they are installed and working properly. If

shields become damaged or loose during operation, stop immediately and fix or replace

them.

·

Inspect output shaft for vines, wire, rope, etc. that may collect around the shaft and tear up

the output seal. If a seal is leaking, replace it, or risk overheating and severe damage to the

hydraulic motor.

·

Check the mounting bolts and nuts to be sure that they are correctly secured. If left

unchecked, it could cause excessive vibrating which could damage the equipment.

·

Check the hydraulic hoses for damage and tightness. If a hose is leaking, replace it, or

damage to the hydraulic system on the mower and the skid-steer could occur.

·

Hydraulic flow manifold has no serviceable parts. If hydraulic problems occur, contact

Bush-Whacker for replacement parts.

Summary of Contents for SSM-72

Page 1: ...2017 SSM 72 ...

Page 5: ...5 2017 SSM 72 Safety Decals SSM 72 Master Decal Sheet 6270 ...

Page 18: ...18 2017 SSM 72 Deck Assembly ...

Page 20: ...20 2017 SSM 72 Overhung Load Adapter 041022 ...

Page 22: ...22 2017 SSM 72 Hydraulic System ...

Page 24: ...24 2017 SSM 72 Notes ...

Page 28: ...28 2017 SSM 72 Notes ...

Page 29: ...29 2017 SSM 72 Notes ...