26

2017 SSM-72

041022

DISCLAIMER OF IMPLIED WARRANTIES & CONSEQUENTIAL DAMAGES

Hall Manufacturing’s obligation under this limited warranty, to the extent allowed by law, is in lieu of all warranties,

Implied or expressed,

INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE

and any liability for incidental and consequential damages with respect to the sale or use

of the equipment warranted. Such incidental and consequential damages shall include but not limited to: transportation

charges loss of income; rental of substitute equipment, and expenses due to loss, damage, detention or delay in the deliv-

ery of equipment or parts resulting from acts beyond the control of Hall Manufacturing.

IMPROVEMENTS OR CHANGES

Hall Manufacturing reserves the right to make improvements of changes in design and specification at any time without

incurring any obligation to owners of units previously sold.

WARRANTY CLAIMS PROCEDURE

Warranty claims must be delivered to Hall Manufacturing within thirty (30) days after the warranty service work was

performed.

Hall Manufacturing will approved or deny claim within thirty (30) days of receiving a claim.

Hall Manufacturing will issue credit for all genuine Bush-Whacker parts or components as well as all approved

Dealership employee labor time at a rate of $30.00 per hour within thirty (30) days of the claim approval.

Defective parts must be held for inspection for ninety (90) days after the work is performed. Hall Manufacturing

may request that parts be returned to the Hall Manufacturing factory for inspection.

ACKNOWLEDGEMENT REQUIRED

Hall Manufacturing shall have no obligation under this warranty unless the Owner Registration Card, included with your

Operators Manual, is signed by Owner and Dealer or Dealer’s Agent and is delivered along with a copy of the original

Bill of Sale from the Dealer to Hall Manufacturing within sixty (60) days from the date of sale.

─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─ ─

COMPLETE THE WARRANTY REGISTRATION CARD

(ON THE FOLLOWING PAGE)

PLACE IN AN ENVELOPE ALONG WITH THE ORIGINAL BILL OF SALE

MAIL TO:

HALL MANUFACTURING, INC.

P. O. BOX 5638

NORTH LITTLE ROCK, AR 72119

Summary of Contents for SSM-72

Page 1: ...2017 SSM 72 ...

Page 5: ...5 2017 SSM 72 Safety Decals SSM 72 Master Decal Sheet 6270 ...

Page 18: ...18 2017 SSM 72 Deck Assembly ...

Page 20: ...20 2017 SSM 72 Overhung Load Adapter 041022 ...

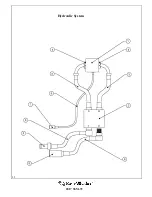

Page 22: ...22 2017 SSM 72 Hydraulic System ...

Page 24: ...24 2017 SSM 72 Notes ...

Page 28: ...28 2017 SSM 72 Notes ...

Page 29: ...29 2017 SSM 72 Notes ...