Summary of Contents for ST-104

Page 1: ...2010 ...

Page 4: ...4 2010 ST 104 Safety Section ...

Page 12: ...12 2010 ST 104 General Maintenance Tips ...

Page 19: ...19 2010 ST 104 Parts book ...

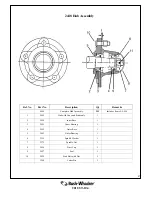

Page 22: ...22 2010 ST 104 3869 Gear Box ...

Page 24: ...24 2010 ST 104 2033 Transfer Gear Box USE NUMBER 0 WEIGHT OIL ONLY ...

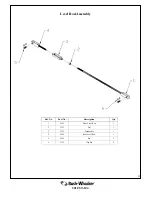

Page 26: ...26 2010 ST 104 4050 Main Drive Shaft for Lift Type ...

Page 36: ...36 2010 ST 104 ...

Page 37: ...37 2010 ST 104 Optional Equipment and Other Items not Illustrated ...

Page 42: ...42 2010 ST 104 4059 Complete Drive Shaft For Pull Type ...

Page 44: ...44 2010 ST 104 5038 Constant Velocity Drive Shaft ...

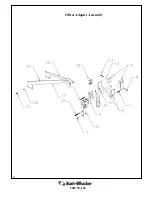

Page 52: ...52 2010 ST 104 Offset Adapter Assembly ...

Page 58: ......

Page 59: ...59 2010 ST 104 Notes ...