16

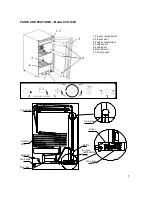

REVERSING THE DOOR (OPTION) – Models XCD-100 and XCD-100D

How to reverse the door

Remove the lower hinge by loosening and removing the screws with screwdriver (2).

Carefully lower the door and remove it.

Remove the three screws from the left top hinge(1) position, take the plastic part off the hinge position.

Remove the three screws from the right top hinge and take off the hinge, insert the plastic part, rivet the

three screws thereafter.

Take off the lower hinge and fix it to the opposite side.

Take the door. Insert the lower hinge axle into the right bottom hole of the door.

Fix the spare hinge to the left top position of the cabinet. Adjust the door, make it straight and in alignment

with the cabinet.

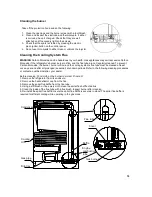

Note: As the door gasket gets pressed-in during shipment, after reversing the door the gasket might have to

be reset. This will be good for seal to avoid any air escaping. If there is a gap between the cabinet and the

door gasket, set the gasket by gently pulling it out to seal the gap. If necessary, you are recommended also to

use the hair drier to warm the gasket to get rid of the gap.