10

OPERATING INSTRUCTIONS

Warning

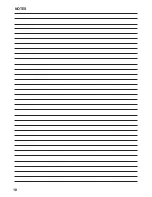

The engine oil should be classification API, class SAE 10W-40 in -15°C ~ 40°C.The oil viscosity is shown in Fig. 13.

4. Start the engine at least three metres away from the area where the fuel tank has been filled up in order to avoid any

risk of fire.

• Danger of fire and burn injuries.

• Always use extreme care when handling fuel! Fuel is highly flammable.

• Never attempt to fuel the blower if the fuel system components are damaged or are leaking.

• Never attempt to refuel the engine while it is running or still warm, allow it to cool before fuelling.

• Never smoke or light any fires near the blower or fuels.

• Aways transport and store fuels in an approved container.

• Never place flammable material close to the engine muffler.

• Do not use petrol which contains ethanol or methanol as it may damage the fuel lines and other engine parts.

• If fuel must be stored longer than 30 days, it should first be treated with a stabilizer or similar product.

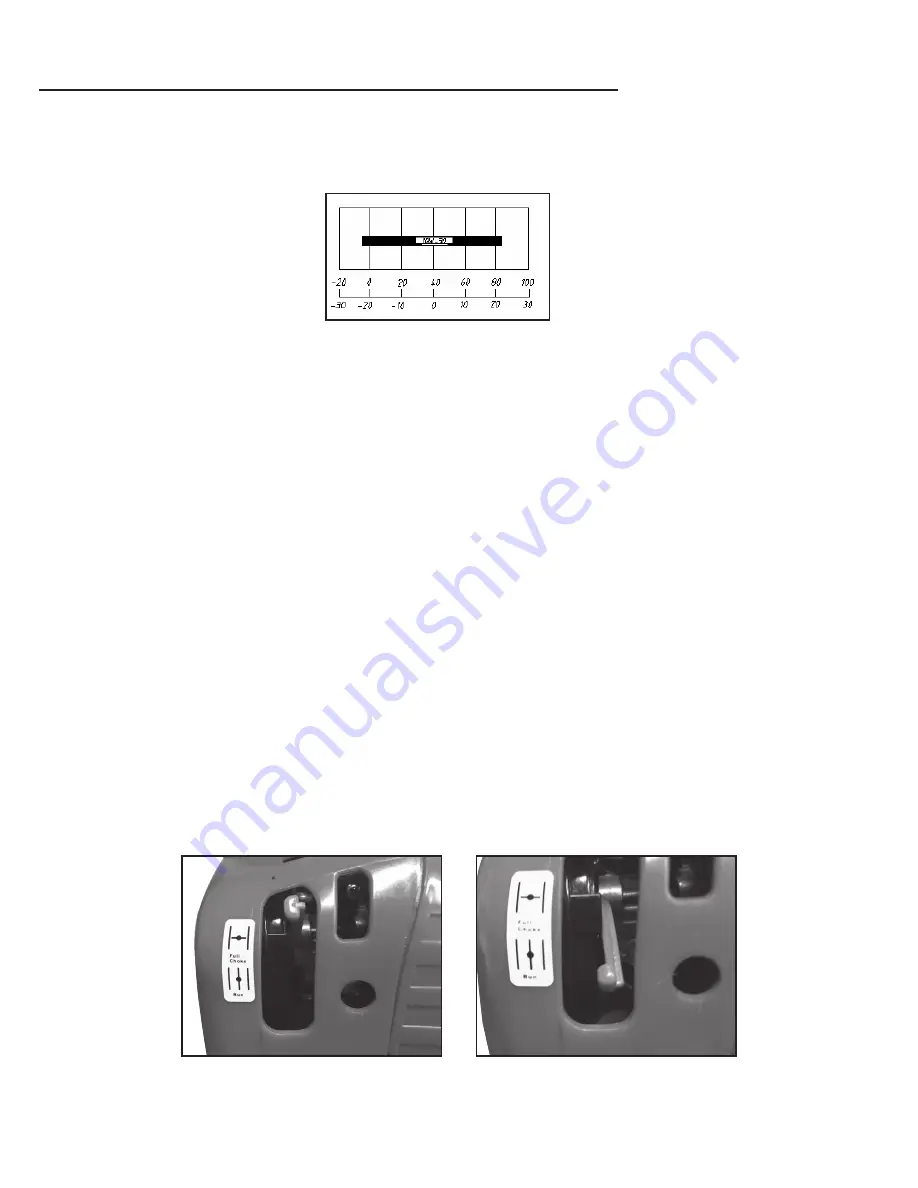

Choke Control

• If the engine is cold you will need to use the choke control.

14

·

If the oil is dirty, it needs to be

replaced.

Warning

!

The engine oil should be

classification API, class SAE 10W-30

in -15

℃

~

40 .The oil viscosity is

℃

shown in Fig.3

:

Fig.3

4.Start the engine at least three metres away from the area where the fuel

tank has been filled up in order to avoid any risk of fire.

·

Danger of fire and burn injuries.

·

Always use extreme care when handling fuel! Fuel is highly

flammable.

·

Never attempt to fuel the blower if the fuel system components are

damaged or are leaking.

·

Never attempt to refuel the engine while it is running or still warm,

allow it to cool before fuelling.

·

Never smoke or light any fires near the blower or fuels.

·

Aways transport and store fuels in an approved container.

·

Never place flammable material close to the engine muffler.

·

Do not use petrol which contains ethanol or methanol as it may

damage the fuel lines and other engine parts.

Start position (choke closed)

Run Position (choke open)

10W - 40

Fig. 13

Fig. 14

Fig. 15

Summary of Contents for BRV2601

Page 1: ...1 BLOWER VAC BRV2601 OPERATOR S MANUAL ...

Page 18: ...18 NOTES ...

Page 19: ...19 NOTES ...