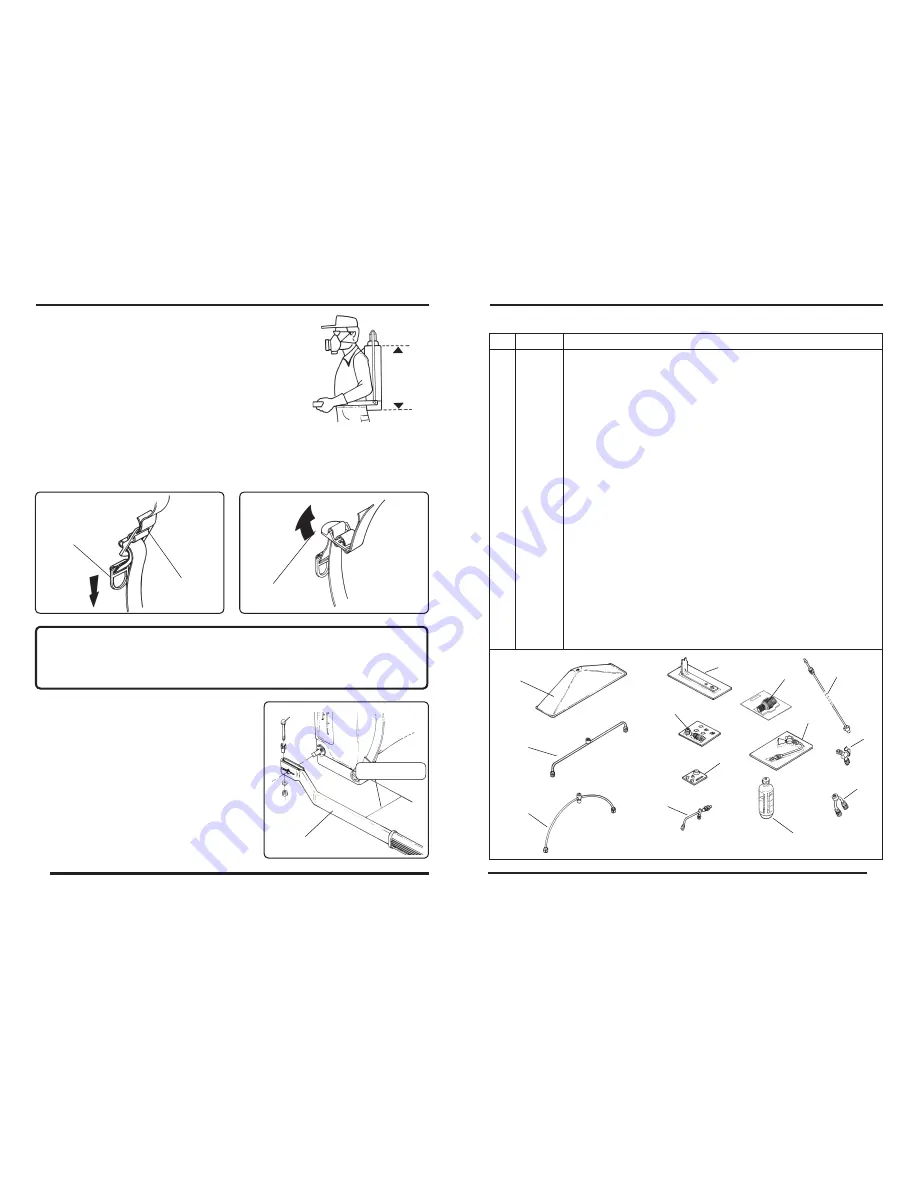

TIGHTENING

- Hold firmly the strap buckle with one hand

and pull the handle downward with the other

hand.

LOOSING

- Hold firmly the strap buckle with one hand

and pull the strap backward with the other

hand.

Handle

Buckle

Buckle

11- ATTENTION

- Cover diaphragm

- Tank bottom

- Wand

- Trigger valve

After assembling the sprayer, fill the tank

with clean water and check for leakage on

the following parts:

Parallel

2

1

04

12- INVERT THE OPERATION SIDE

If it is necessary to invert the pumping lever side,

proceed as follows:

- Remove the bolt (1).

- Remove the pumping lever (2).

- Install the pumping lever on the other side.

NOTE: On inverting the position of the lever, do

not move the chamber so as not to install the

lever improperly.

- Tighten the bolt.

13

10- ADJUSTING THE STRAP

The tank is contoured for the operator comfort. The shoul-

der straps can be quickly adjusted to properly position the

sprayer on the operator's back.

OPTIONAL ACCESSORIES FOR MANUAL KNAPSACK SPRAYERS

Item Part no.

Use

01 761882 Spray guard: prevents nonselective herbicides from drifting.

02 902296 Boom 500: improves the coverage and increases the productivity.

03 907873 Pliable boom: holds the required shape for better coverage.

04 560409 Lance with valve: used for growth-deterrent application.

05 728139 Extension 600: increases the application reach.

06 100016 Extesion 160 - 2 nozzles: increases the coverage and penetration.

07 646901 Flow calibrator bottle: is used to calibrate the sprayer, thus

reducing the waste.

08 336115 Nozzle Y: improves the coverage.

09 452284 Wrench for general maintenance.

10 565648 Non-drip valve: reduces the waste.

11 834382 X-15 basic repair kit. It contains: piston cup, diaphragm, trigger

valve cap and needle assembly.

12

590513

ECOVALVE-Constant Pressure Valve (1; 1,5 and 2 kgf/cm²) -

ensures constant pressure without waste.

13 834390 Cone nozzles kit. It contains: discs 12 and 10, swirl core A

and P, nozzle cap, red adjustable nozzle, nozzle strainer.

1

7

9

8

5

10

11

12

6

4

3

2

13