Chapter 4

User

Interface

Page 4-15

4.6 Maintenance

Schedule

The maintenance schedule in

below applies to equipment operated daily on an

8-hour basis. If the equipment is to be used more frequently, the maintenance schedule

must be adjusted accordingly.

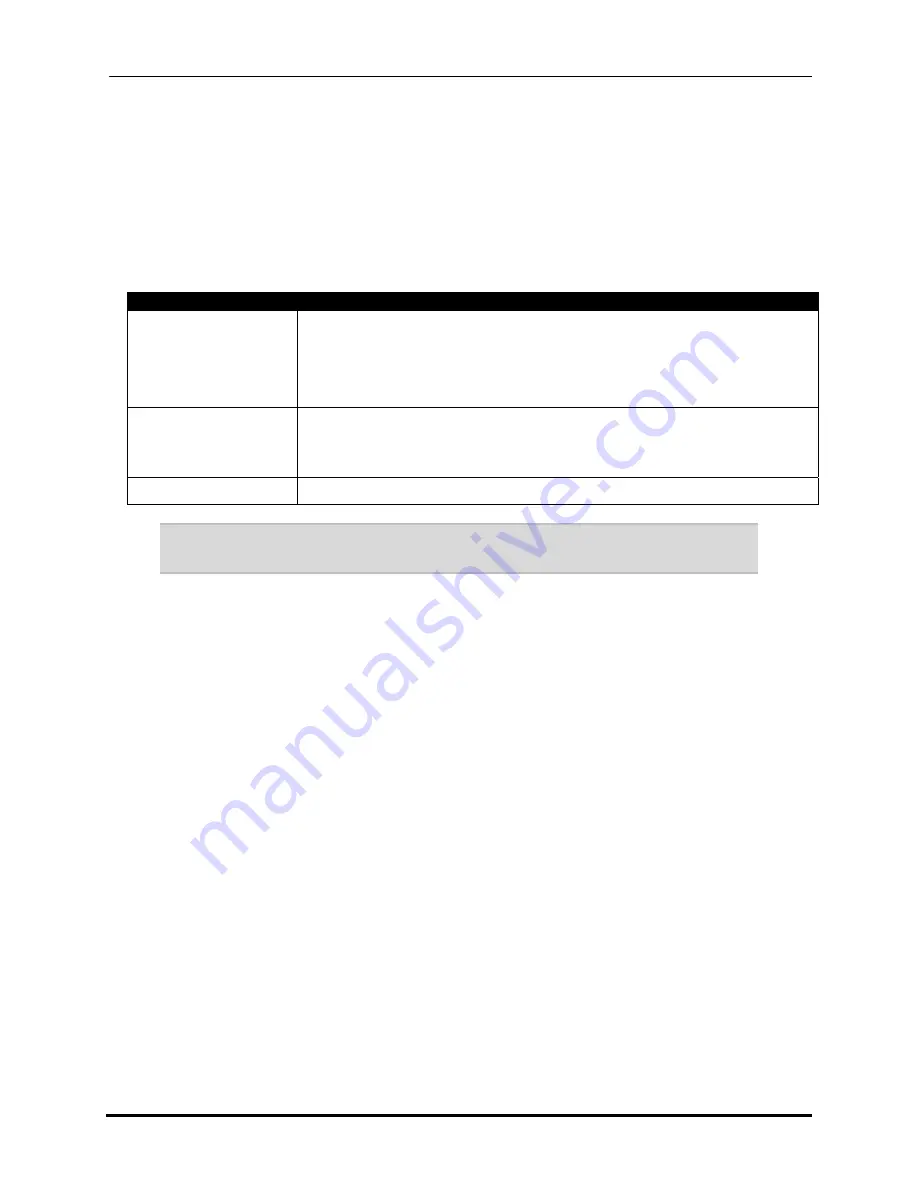

Table 4-3:

Head Maintenance Schedule

Period

Maintenance Function

Daily

Remove the front safety cover and clean any debris, which may have fallen

into the machine.

Remove any labels, which may have settled on the rollers and sensor bin.

Wipe debris off all sensors to prevent malfunction.

Monthly

Grease all moving parts to help reduce wear due to friction.

The peel point sensor must be cleaned to prevent material build up. An air

compressor is recommended.

Semi Annually

Examine all moving parts for wear. Replace if necessary.

Note

: Acquiring a small air compressor is recommended as compressed air is useful in

removing debris.

Buskro Ltd.

BK731 Labeler

Summary of Contents for BK731

Page 1: ...BK731 Labeler Part No 9100619 User s Guide V1 0 ...

Page 5: ...General Information Chapter 1 1 0 General Information Buskro Ltd BK731 Labeler ...

Page 12: ...BK731 Options Chapter 2 2 0 BK731 Options Buskro Ltd BK731 Labeler ...

Page 23: ...Mechanical Adjustments Chapter 3 3 0 Mechanical Adjustments Buskro Ltd BK731 Labeler ...

Page 31: ...User Interface Chapter 4 4 0 User Interface Buskro Ltd BK731 Labeler ...