INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 14 of 43

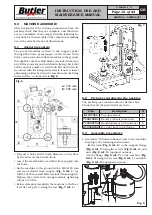

FIT A TYPE-APPROVED PLUG

TO THE MACHINE CABLE (THE

GROUND WIRE IS YELLOW/GREEN

AND MUST NEVER BE CONNECTED

TO ONE OF THE PHASE LEADS).

MAKE SURE THAT THE ELECTRI-

CAL SYSTEM IS COMPATIBLE

WITH THE RATED POWER AB-

SORPTION SPECIFIED IN THIS

MANUAL AND APT TO ENSURE

THAT VOLTAGE DROP UNDER

FULL LOAD WILL NOT EXCEED

4% OF RATED VOLTAGE (10%

UPON START-UP).

VERSION WITH

SINGLE-PHASE MOTOR

On delivery, the machine is pre-set to operate at a

single-phase voltage of 200 ÷ 265 V - 50/60 Hz.

FAILURE TO OBSERVE THE ABOVE

INSTRUCTIONS WILL IMMEDIATE-

LY INVALIDATE THE WARRANTY.

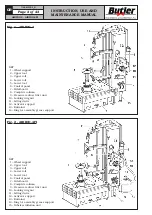

10.1 Working area modification

After the delivery, the machine is prearranged to op-

erate on wheel of 50” maximum diameter and a rim

diameter (10” - 30”). It’s also possible to move the tools

column to enlarge the working area from 52” (with rim

diameter of 12” - 32”) and up to 54” (with rim diameter

of 14” - 34”) (see

Figure 11

).

Fig. 11

The column is moved by unloosing the fixing screws of

the base (

Fig.

11 ref. A

) to the column (

Fig.

11 ref. B

)

and by sliding the base (

Fig.

11 ref. A

) into the proper

slots up to the required measure.

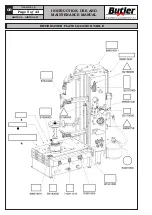

MAKE SURE THAT THE TYRE-

CHANGER COLUMN IS STABLE

BY USING A CABLE, HELD BY A

HOIST, TO BE HOOKED TO THE

APPROPRIATE LIFTING TRAV-

ERSE (FIG. 12 REF. 7).

1. Remove the lateral guards (

Fig.

12 ref. 1-2

) of the

machine.

2. Unscrew the screws (

Fig.

12 ref. 3

) and the nuts

near the central slots (

Fig.

12 ref. 4

) paying atten-

tion not to remove the nuts from the proper screws.

3. Remove the six remaining screws (

Fig.

12 ref. 5

).

4. Move the base (

Fig.

12 ref. 6

) into the required

position (to 52” or 54”) and if necessary, use a lifting

device (

Fig.

12 ref. 7

).

5. Lock the base three screws (

Fig.

12 ref. 3

) with a

couple of 80 Nm.

6. Place six screws (

Fig.

12 ref. 5

) previously removed

and lock them on the bases side with a couple of

80 Nm.

7. Remount the lateral guards (

Fig.

12 ref. 1-2

) of

the machine.

7104-M009-2_B

AIKIDO.4 - AIKIDO.4FI