INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 30 of 43

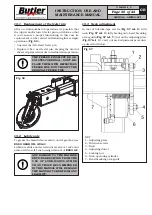

13.1 Replacement of the feeler pin

After a certain number of operations it’s possible that

the (upper and/or lower) feeler pin can deform so that

it can’t ensure a proper functioning; in this case its

replacement can be carried out following these simple

operations (

Fig.

56

):

• Unscrew the deformed feeler pin

• Replace it by a new feeler pin, keeping the head of

the screw pressed in order to facilitate this operation.

THE FEELER PINS MUST BE AB-

SOLUTELY ORIGINAL; DON’T RE-

PLACE THEM WITH IMPROVISED

FEELER PINS, DON’T MODIFY THE

ORIGINAL FEELER PINS.

Fig. 56

13.2 Lubricants

To grease the mandrel movement control gearbox, use

ESSO GEAR OIL GX140

.

Lubricate slides and screws/nut screws or racks and

pinion with a soft brush using lubricant of

ESSO GP

.

ANY DAMAGE TO THE MACHINE

DEVICES RESULTING FROM THE

USE OF LUBRICANTS OTHER

THAN THOSE RECOMMENDED

IN THIS MANUAL WILL RELEASE

THE MANUFACTURER FROM ANY

LIABILITY.

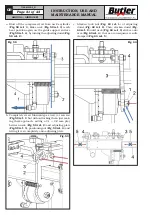

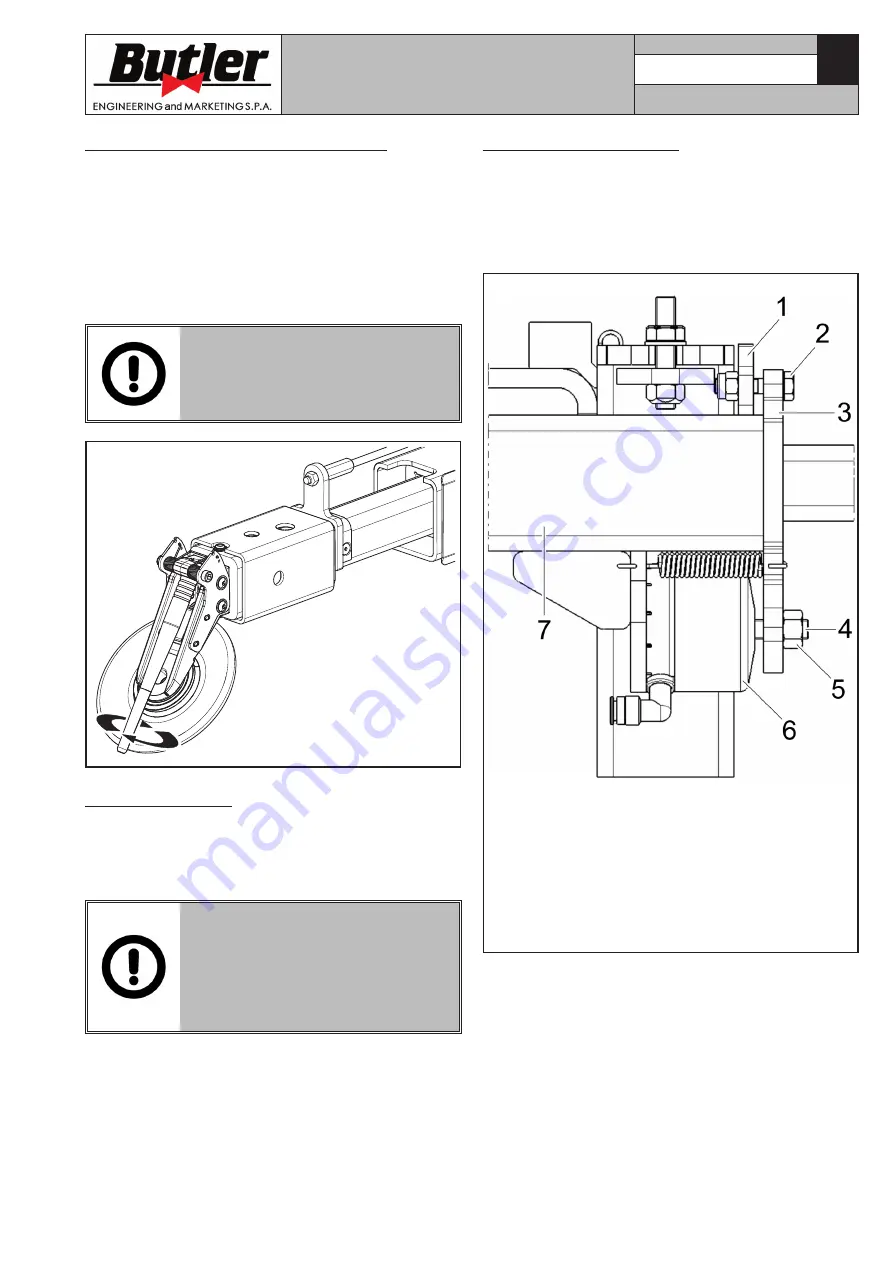

13.3 Neck adjustment

In case of fulcrum-type screws (

Fig.

57 ref. 2

) with

neck (

Fig.

57 ref. 3

) fully beating onto bead breaking

arm’s guide (

Fig.

57 ref. 7

) (not on the adjusting plate

(

Fig.

57 ref. 1

)), carry out neck adjustment procedure

as described below.

Fig. 57

KEY

1 – Adjusting plate

2 – Fulcrum screws

3 – Neck

4 – Adjusting dowel

5 – Locking nut

6 – Neck operating cylinder

7 – Bead breaking arm guide

7104-M009-2_B

AIKIDO.4 - AIKIDO.4FI