INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 28 of 67

12.0 MACHINE SWITCHING ON AND OFF

BEFORE MACHINE SWITCHING

ON, MAKE SURE THE SMART

CARD (FIG. 17 REF. 3) FOR PRO-

GRAM ENABLING AND MEMORY

BANK IS INSERTED IN THE PRO-

VIDED READER, IN THE PC BACK

PART (SEE Fig. 17).

12.1 Smart card for program protection and

memory bank

All machines are equipped with a PC (

Fig. 17 ref. 1

)

with SMART CARD reader (

Fig. 17 ref. 2

).

This SMART CARD (

Fig. 17 ref. 3

), inserted in the

reader allows the functioning of the program itself and

enables access to vehicles DATABASE.

Fig. 17

Each machine is equipped with its own single SMART

CARD, , which can not absolutely be replaced by a smart

card of another machine.

When such SMART CARD, is removed or replaced, the

program displays an error message and does not allow

to carry on.

IN CASE OF SMART CARD MAL-

FUNCTION DURING PC SWITCH-

ING ON PHASE, CONTACT THE

MANUFACTURER, WHICH WILL

AUTHORIZE THE RETURN OF THE

FAULTY SMART CARD. IT WILL

BE REPLACED WITH A WORKING

ONE WITH THE SAME USB SERIAL

NUMBER.

13.0 USING THE MACHINE

13.1 Preliminary operations - Preparing the

wheel

• Remove the wheel balancing weights from both sides

of the wheel.

• Remove the valve stem and allow the tyre to com-

pletely deflate.

• Establish from which side the tyre should be de-

mounted, checking the position of the groove.

• Find the rim locking type.

• Try to establish the special types of wheels, such as

“EH2” and “EH2+”, in order to improve locking, bead

breaking, assembly and disassembly performances.

W H E N H A N D L I N G W H E E L S

WEIGHING MORE THAN 10 KG

AND/OR WITH A FREQUENCY

OF MORE THAN 20/30 WHEELS

PER HOUR, A LIFTING DEVICE

SHOULD BE USED.

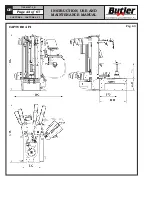

13.2 Wheel clamping

All wheels must be locked on the rubber plate (

Fig. 18

ref. 1

) through the central hole using the proper locking

ring nut (

Fig. 18 ref. 2

).

Fig. 18

IN CASE OF USE OF RIMS WITH-

OUT CENTRAL HOLE, IT’S NECES-

SARY TO USE THE PROPER FIX-

TURE (AVAILABLE ON DEMAND).

CAPTURE 4 - CAPTURE 4 FI

7104-M007-4_B