INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 9 of 67

OPERATORS MUST WEAR SUIT-

ABLE WORK CLOTHES, PROTEC-

TIVE GLASSES AND GLOVES,

AGAINST THE DANGER FROM

THE SPRAYING OF DANGEROUS

DUST, AND POSSIBLY LOWER

BACK SUPPORTS FOR THE LIFT-

ING OF HEAVY PARTS. DANGLING

OBJECTS LIKE BRACELETS MUST

NOT BE WORN, AND LONG HAIR

MUST BE TIED UP. FOOTWEAR

SHOULD BE ADEQUATE FOR THE

TYPE OF OPERATIONS TO BE CAR-

RIED OUT.

• The machine handles and operating grips must be

kept clean and free from oil.

• The workshop must be kept clean and dry. Make sure

that the working premises are properly lit.

The machine can be operated by a single operator.

Unauthorized personnel must remain outside the

working area, as shown in

Fig. 11.

Avoid any hazardous situations. Do not use air-

operated or electrical equipment when the shop is

damp or the floor slippery and do not expose such

tools to atmospheric agents.

• When operating and servicing this machine, carefully

follow all applicable safety and accident-prevention

precautions.

The machine must not be operated by professionally

unskilled persons.

• During inflation do not lean on the tyre or remain

above it. When beading in the tyre, keep hands away

from tyre and the rim edge.

• During inflation always stay to the side of the machine

and never in front of it.

IN CASE OF A CHANCE SUPPLY

FAILURE (WHETHER ELECTRIC-

ITY OR COMPRESSED AIR), MOVE

THE PEDALS TO THE NEUTRAL

POSITION.

5.0 PACKING AND MOBILIZATION FOR

TRANSPORT

HAVE THE MACHINE HANDLED BY SKILLED

PERSONNEL ONLY.

THE LIFTING EQUIPMENT MUST WITHSTAND

A MINIMUM RATED LOAD EQUAL TO THE

WEIGHT OF THE PACKED MACHINE (SEE

PARAGRAPH “TECHNICAL SPECIFICATIONS”).

The machine is packed partially assembled.

Movement must be by pallet-lift or fork-lift trolley.

The fork lifting points are indicated on the packing.

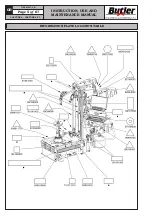

Fig. 3

CAPTURE 4 - CAPTURE 4 FI

7104-M007-4_B