INSTRUCTION, USE AND

MAINTENANCE MANUAL

Page 11 of 36

GB

10.0 ASSEMBLY AND PREPARATION FOR

USE

After having freed the various components from the

packing check that they are complete, and that there

are no anomalies, then comply with the following in-

structions for the assembly of the components making

use of the attached series of illustrations.

10.1 Assembly procedures

Remove the packaging and free the machine from the

wrapping. Lift the machine and position it on the floor.

10.2 Post assembly

In case the post is supplied demounted, proceed fol-

lowing the instructions below.

1. Remove the fixing elements needed to fix the machine

to the pallet.

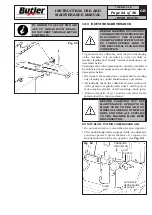

2. Unpack the vertical post (

Fig. 6 ref. 1

) and put it

vertically onto the base.

3. Put the post (

Fig. 6 ref. 1

) onto the base (

Fig. 6

ref. 2

) and fit the pin (

Fig. 6 ref. 3

) into the spe-

cial hole (

Fig. 6 ref. 4

) and block it through the

washers (

Fig. 6 ref. 5

), the spacers (

Fig. 6 ref. 6

)

and the screws (

Fig. 6 ref. 7

). Fix the rod of post

turnover control (

Fig. 6 ref. 8

) cylinder using the

pin (

Fig. 6 ref. 9

) and the seegers (

Fig. 6 ref. 10

).

1

2

7 6

5

3

9 10

6

7

10

8

4

5

Fig. 6

4. At the end mount the rod covering by means of the

supplied screws and washers.

10.3 Bead breaker arm mounting

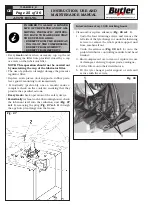

Secure the beading arm vane (

Fig. 7 ref. 1

) using the

washers (

Fig. 7 ref. 2

) and the nut (

Fig. 7 ref. 3

),

on issue (nut and washers are clamped on the bead

breaker vane).

1 2 3

Fig. 7

10.4 Tubeless inflation mounting (only for

versions with tubeless inflation)

1. Mount the tank (

Fig. 8 ref. 1

) on the base rear part,

as shown in

Fig. 8

, using the screws (

Fig. 8 ref. 2

)

(tightening torque approx. 8 N·m), the washers

(

Fig. 8 ref. 3

) and the nuts (

Fig. 8 ref. 4

).

2

2

1

3

4

3

4

Fig. 8

7300-M023-0_B

HP441S.XX - HP441S.XXFI

HP441SQ.XX - HP441SQ.XXFI