INSTRUCTION, USE AND

MAINTENANCE MANUAL

Page 16 of 36

GB

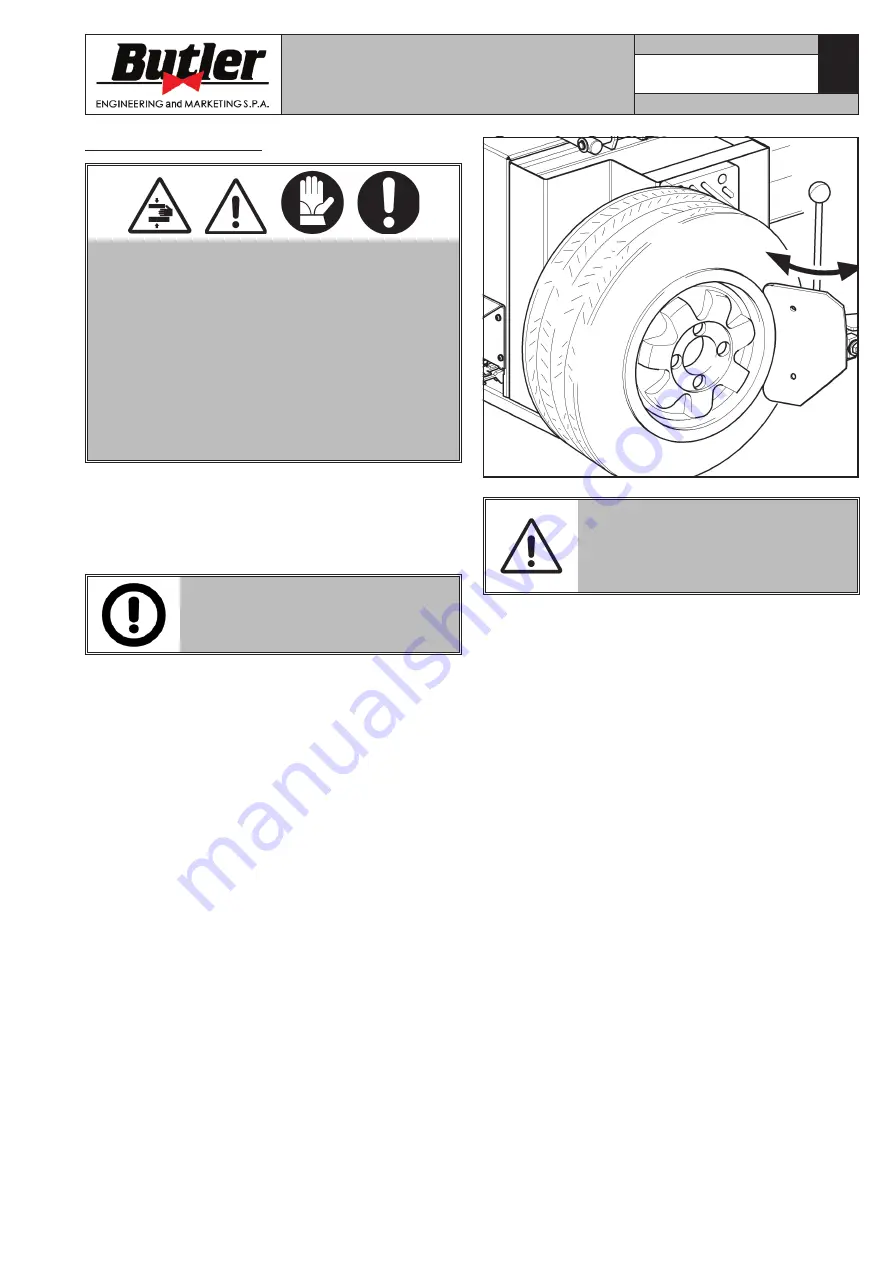

12.3 Bead breaking

TYRE BEADING MUST BE CARRIED OUT AF-

TER THE TYRE HAS BEEN COMPLETELY DE-

FLATED AND OBSERVING ALL SAFETY RULES:

BEADING PEDAL START-UP CAUSE SUDDEN,

STRONG ARM CLAMPING, THUS REPRESENT-

ING POTENTIAL CRUSHING DANGER FOR

ANYTHING WITHIN THE OPERATING AREA.

DURING TYRE BEADING DO NOT LEAN HANDS

ON TYRE SIDES. DURING TYRE BEADING

SUDDEN NOISE LEVEL PEAKS CAN OCCUR:

THEREFORE THE USE OF SAFETY EARCAPS

IS RECOMMENDED.

After preparing the wheel as described in the previous

point, follow the instructions given below to carry out

the bead breaking procedure:

1. Position the wheel as indicated in

Fig. 14

and move

the bead breaker tool toward the edge of the rim.

PLACE THE VANE SO THAT IT CAN

OPERATE ON TYRE SIDE AND NOT

ON THE RIM.

2. Operate the bead breaker vane by pressing the rela-

tive pedal until the bead has detached. If the bead

does not detach the first time, repeat the operation,

on different points of the wheel, until it has come

away completely.

3. Reverse the position of the wheel and repeat the

operation on the other side.

4. Lubricate the tyre carefully along the entire cir-

cumference of the bead on both sides. Failure to

lubricate might cause friction between the mounting

tool and the tyre, and would cause damage to the

tyre and/or the bead.

Fig. 14

NEVER INSERT ANY PART OF

YOUR BODY BETWEEN THE BEAD

BREAKER TOOL AND THE TYRE,

OR BETWEEN THE TYRE AND THE

WHEEL SUPPORT.

7300-M023-0_B

HP441S.XX - HP441S.XXFI

HP441SQ.XX - HP441SQ.XXFI