INSTRUCTION, USE AND

MAINTENANCE MANUAL

Page 25 of 36

GB

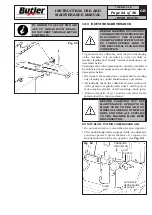

IN ORDER TO ALLOW A LONGER

LIFE OF THE FILTER AND OF ALL

MOVING PNEUMATIC DEVICES,

YOU HAVE TO MAKE SURE THAT

THE SUPPLIED AIR IS:

• EXEMPT FROM THE LUBRICAT-

ING OIL OF THE COMPRESSOR;

• EXEMPT FROM HUMIDITY;

• EXEMPT FROM IMPURITY.

• Every

week

and/or when necessary, top up the oil

tank using the filler hole provided closed by a cap

or screw on the lubricator filter.

NOTE: This operation should not be carried out

by unscrewing the cup of the lubricator filter.

• The use of synthetic oil might damage the pressure

regulator filter.

• Replace worn pieces (tool supports, rubber pads,

lever guard, mounting tool) immediately.

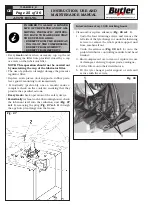

• Periodically (preferably once a month) make a

complete check on the controls, ensuring that they

provide the specified actions.

•

Every week

check operation of the safety device.

•

Periodically

(at least each 100 working hours) check

the lubricant level into the reduction unit (

Fig. 27

ref. 1

) removing the plug (

Fig. 27 ref. 2

) through

the spy hole prearranged on the frame.

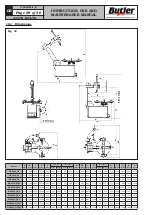

Fig. 27

Interventions every 1000 working hours

• Clean and/or replace silencers (

Fig. 28 ref. 1

):

1. Undo the four retaining screws and remove the

left side of the tyre changer or undo the fastening

screws to remove the whole pedal support unit

from machine front;

2. Undo the silencers (

Fig. 28 ref. 1

) onto the

pedal distributor controlling mandrel and bead

breaker;

3. Blow compressed air to clean or replace in case

of damages referring to spare parts catalogue;

4. Fit the filters onto their distributors;

5. Fit the tyre changer pedal support or side and

secure with the screws.

1

1

Fig. 28

7300-M023-0_B

HP441S.XX - HP441S.XXFI

HP441SQ.XX - HP441SQ.XXFI