INSTRUCTION, USE AND

MAINTENANCE MANUAL

Page 27 of 36

GB

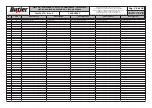

14.0 TROUBLESHOOTING TABLE

Possible troubles which might occur to the tyre-changer are listed below. The manufacturer disclaims all

responsibility for damages to people, animals or objects due to improper operation by non-unauthorised

personnel. In case of trouble, call Technical Service Department for instructions on how to service and/or

adjust the machine in full safety to avoid any risk of damage to people, animals or objects.

In an emergency and before maintenance on tyre-changer, set the main switch to “0” and lock it in this position.

CONTACT AUTHORIZED TECHNICAL SERVICE

do not try and service alone

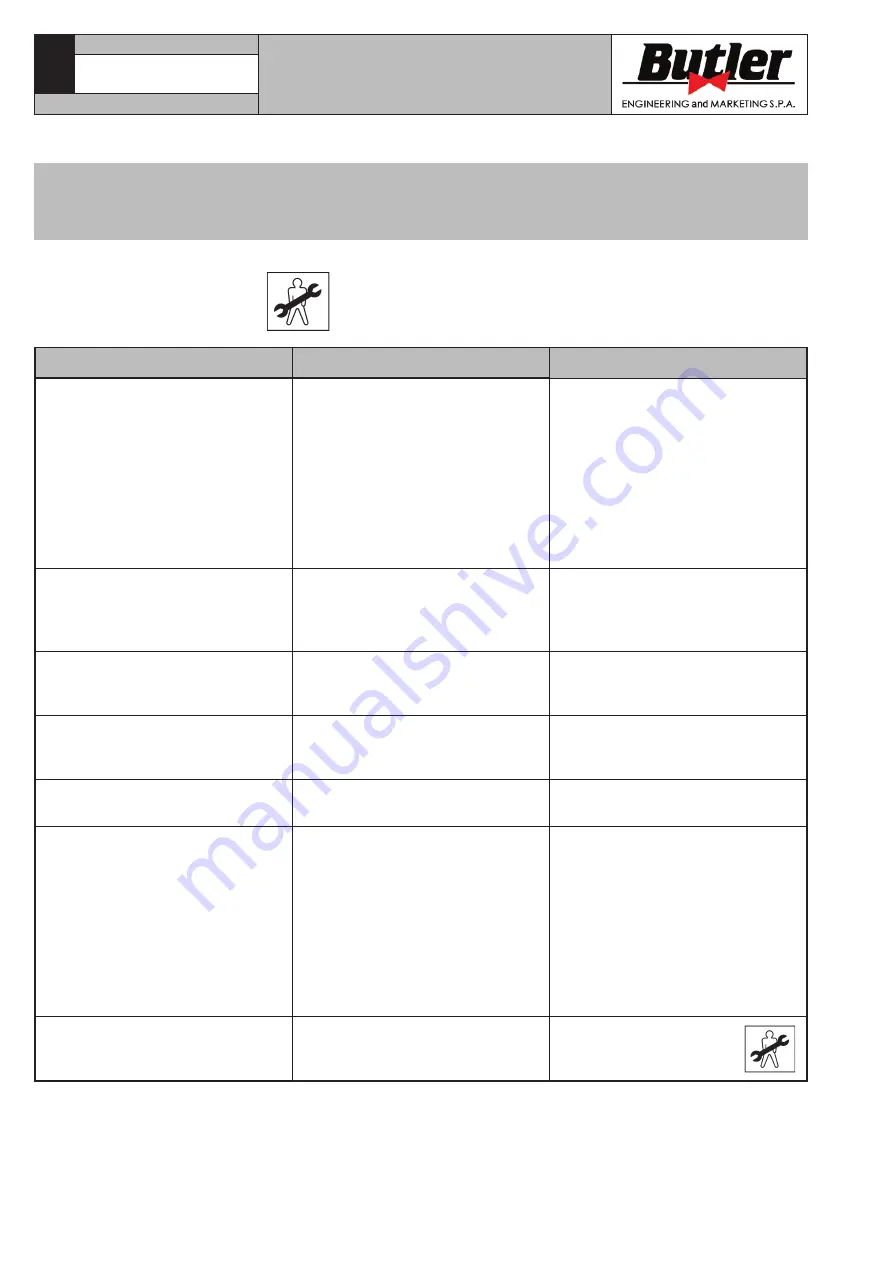

Problem

Possible cause

Remedy

The mandrel does not work if

pedal is pressed.

1. No voltage available.

2. Motor faulty.

3. Safety fuses for machine sys-

tem blown.

1. Check that the plug is properly

connected and power supply

is working.

2. Check for correspondence of

electric data of the machine

with the mains.

3. Check for proper working

conditions. Check connec-

tions and parts (motors and

switches).

The self-centring device stops

during tire assembly/disassem-

bly.

Transmission belt slow or worn

out.

Check for proper working condi-

tions of the transmission belt.

Tension up and/or replace, if

necessary.

The mandrel does not clamp the

rim properly.

1. Clamps worn out.

2. One or more pneumatic cylin-

ders faulty.

1. Replace clamps.

2. Replace pneumatic cylinder

gaskets.

The head gets in contact with the

rim during assembly/disassem-

bly.

1. Clamping plate not adjusted or

faulty.

2. Mandrel retaining screw loose.

1. Adjust or replace the clamping

plate.

2. Tighten the screw.

One or more pedals do not re-

turn to their original position.

1. Return spring released.

2. Return spring broken.

1. Fasten the spring.

2. Replace the spring.

Pneumatic controls do not work

(mandrel, bead breaker, post tilt-

ing and tool clamping).

1. Machine pneumatic system not

connected.

2. Air lines clogged.

1. Check pneumatic connections

and supply.

2. Ensure that the air filter is

clean and undamaged, if fit-

ted. If no air filter is fitted,

remove all dirt into the pneu-

matic system and then fit a

suitable filter.

Clean and/or replace the si-

lencers.

Some single pneumatic devices

do not work (beader, clamps or

post tilting device).

Ensure that device and/or distrib-

utor seals are not damaged.

Call for technical assis-

tance.

7300-M023-0_B

HP441S.XX - HP441S.XXFI

HP441SQ.XX - HP441SQ.XXFI