Page 33 of 106

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

KENDO.30LIGHT-KENDO.30LIGHTFI

7105-M002-0_B

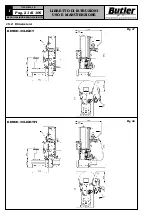

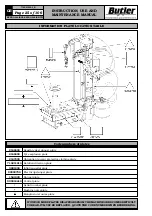

Fig. 15

Fig. 16

KEY (pedal

Pos. B

)

Pos. 1 - Tyre inflation with pressure gauge

Pos. 2 - Tyre inflation with pressure gauge +

inflation nozzle

NOTE:

in case of use of rims without central hole, it’s

necessary to use the proper accessory (available

on demand).

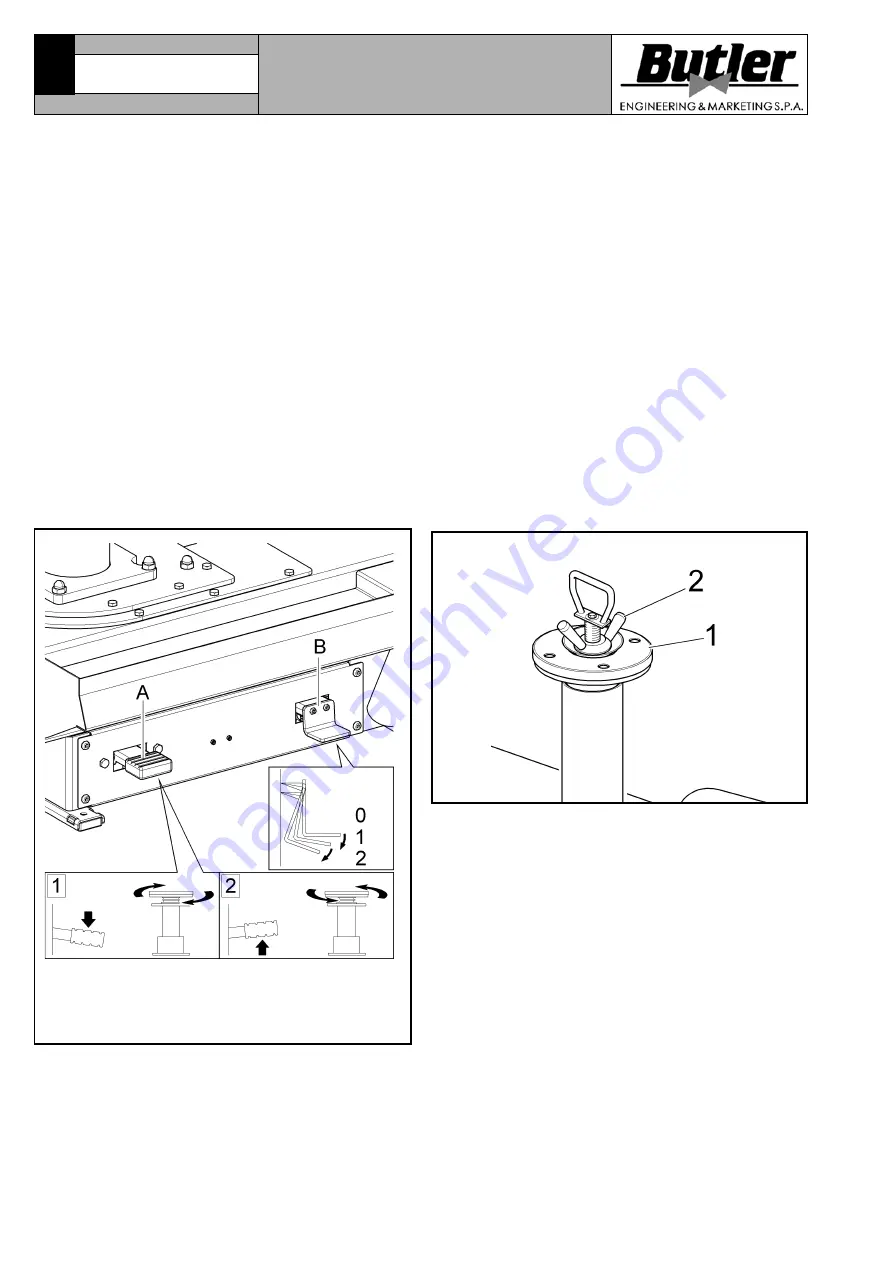

11.2 Pedalboard (see Fig. 15)

The

“pedal A”

has two mechanically holded operative

positions. Pressing it downward the chuck motor ro-

tates in clockwise sense. Lifting the pedal causes a move-

ment in the opposite sense.

NOTE:

Chuck unit speed can be metered continuously

only in clockwise sense: the maximum speed is

reached through a progressive speed on the

pedal.

The

“pedal B”

has a different function depending on the

version on the machine.

Version with inflation with pressure gauge

The inflation pedal in this version has only one func-

tion. A continuous pressure supplies air at a controlled

pressure (max. 4 ± 0,2 bar 58 PSI).

Version with tubeless inflation

The inflation pedal has two functions. The supply of air

at a controlled pressure as in the previous version, and

a second function of a jet of air from the inflation nozzle

to assist the beading in of the tyre.

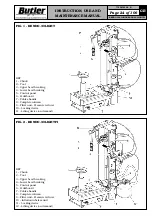

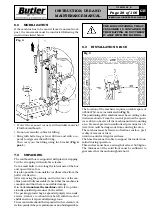

12.0 USING THE MACHINE

12.1 Preliminary operations - Preparing

the wheel

• Remove the wheel balancing weights from both sides

of the wheel.

• Remove the valve stem and allow the tyre to completely

deflate.

• Establish from which side the tyre should be

demounted, checking the position of the channel.

• Find the rim locking type.

• Try to establish the special types of wheels, such as

“EH2” and “EH2+”, in order to improve locking, bead

breaking, assembly and disassembly performances.

12.2 Wheel locking

All rims must be locked on the rubber plate (

Fig. 16

pos. 1

) through the central hole using the proper lock-

ing device (

Fig. 16 pos. 2

).