INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 25 of 66

12.6.3 Mounting

WHEN DEMOUNTING VERY HEAVY

TYRES, IT IS IMPORTANT TO

MOVE THE WHEEL AS CLOSE AS

POSSIBLE TO THE BASE BEFORE

COMPLETING THE OPERATION.

THROUGHOUT TYRE MOUNT-

ING/DEMOUNTING OPERATIONS,

CHECK THAT THE SELF-CEN-

TRING CHUCK CLAMPING PRES-

SURE IS CLOSE TO THE MAXIMUM

OPERATING VALUE (150 BAR).

Tubeless tyre fitting is normally done with the disc

tool; if the wheel

is especially hard to fit, use the hook tool.

With beading disc

Proceed as follows:

• Secure the rim to the mandrel according to the proce-

dure described in paragraph “WHEEL CLAMPING”.

• Adequately lubricate the tyre beads and the rim bead

seat with a suitable lubricant using the provided

brush.

USE ONLY TYRE LUBRICANTS.

SUITABLE LUBRICANTS CONTAIN

NO WATER, HYDROCARBONS, OR

SILICON.

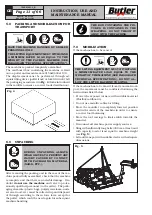

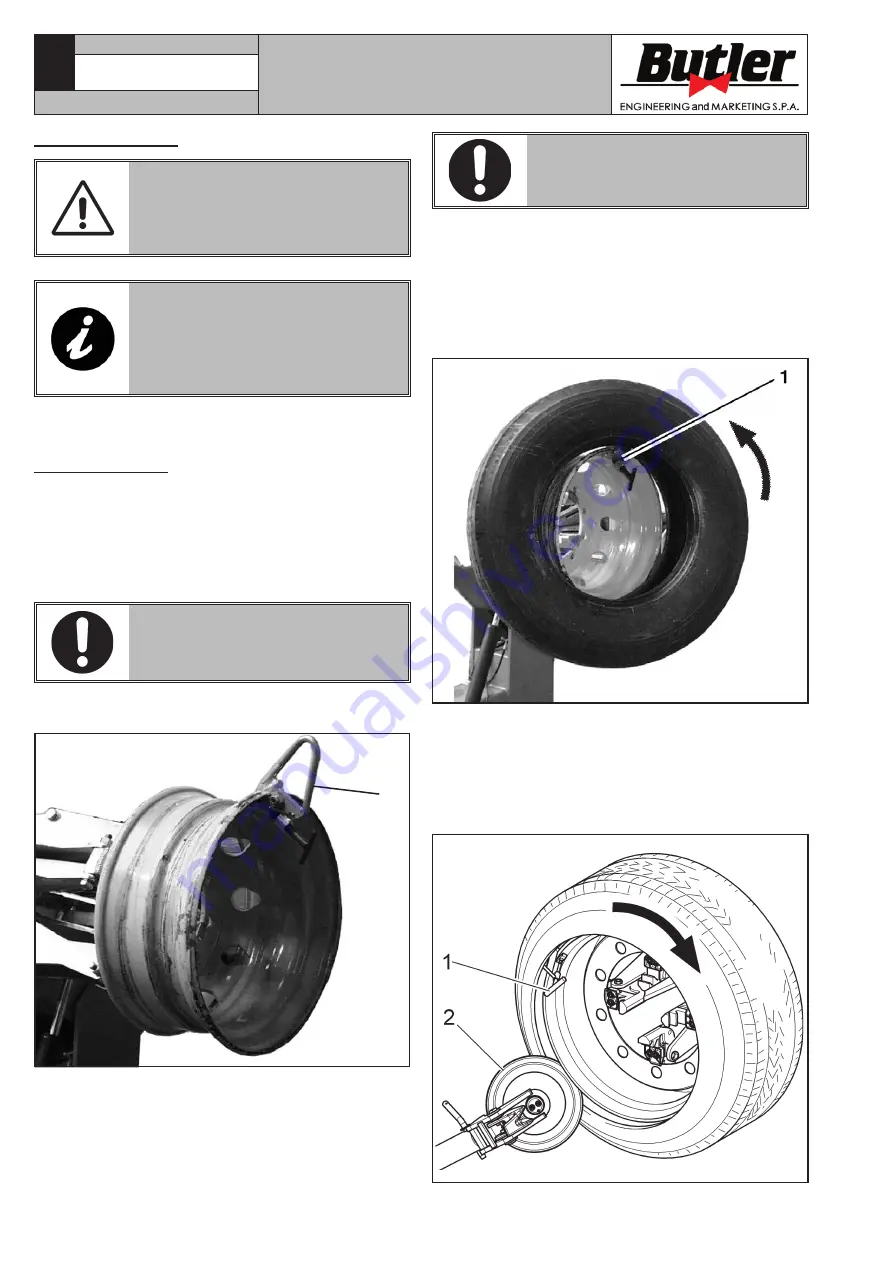

• Mount grippers (

Fig.

_

29 ref.

_

1

) on the external edge

of the rim in the highest point as shown in

Fig.

_

29

.

Fig.

_

29

1

THE GRIPPERS MUST BE TIGHTLY

SECURED TO THE EDGE OF THE

RIM.

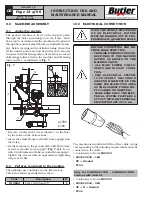

• Move to work position

B

(

Fig.

_

6

).

• Lower the mandrel arm completely. Roll the tyre on

the platform and hook it to clamp (

Fig.

_

30 ref.

_

1

).

• Lift the mandrel arm with the tyre hooked and turn

it counterclockwise by about 15-20 cm; the tyre

will position itself sideways with respect to the rim

Fig.

_

30

).

Fig.

_

30

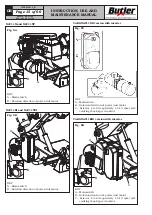

• Move to work position

C

(

Fig.

_

6

).

• Position beading disc (

Fig.

_

31 ref.

_

2

) so that it is

at approximately 1.5 cm (½”) from the edge of the

rim. Fitting clamp (

Fig.

_

31 ref.

_

1

) is at 11 o’clock.

Turn the mandrel until the grippers reach the lowest

point (6 o’clock).

Fig.

_

31

NAV11N - NAV11NT

NAV11EI - NAV11TEI

7505-M001-3_B