INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 35 of 66

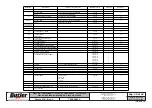

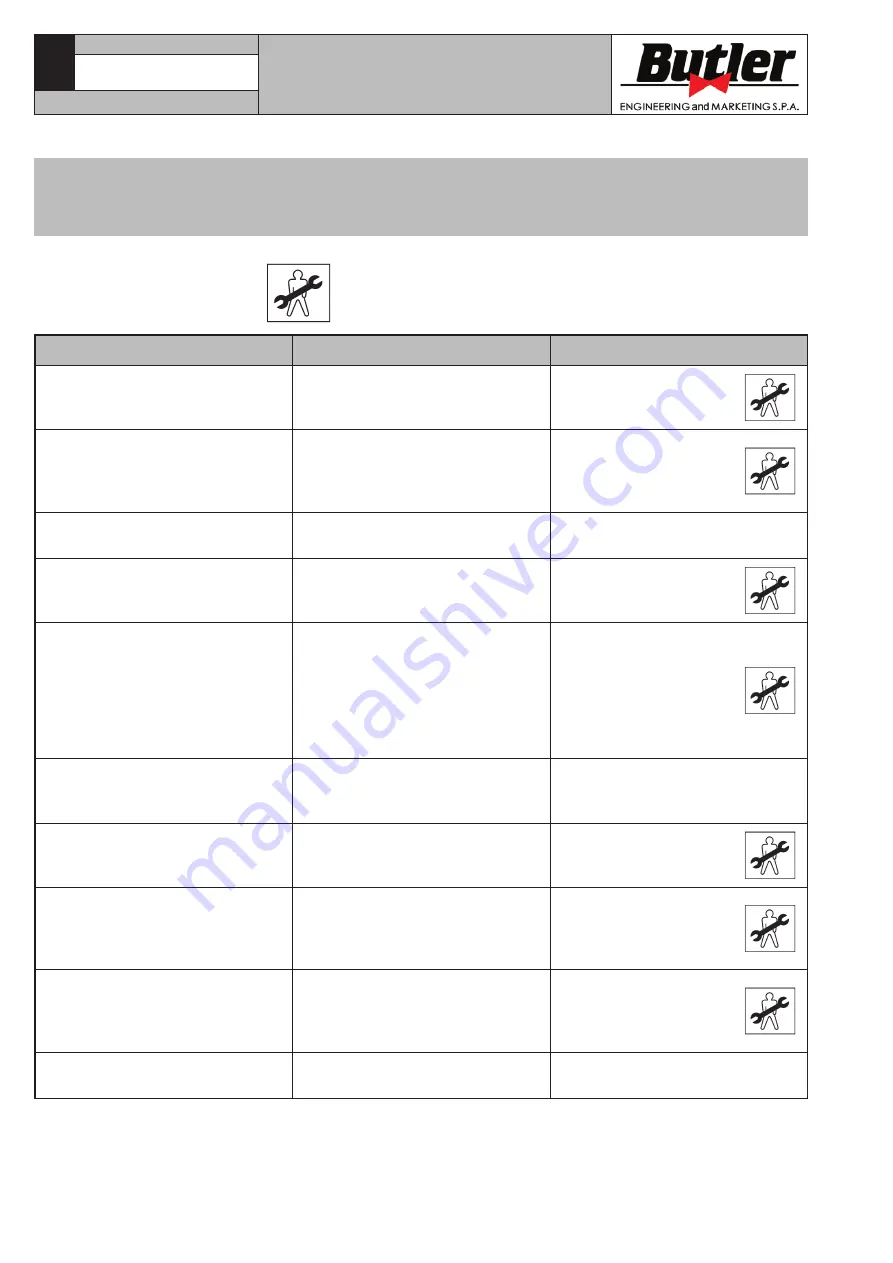

14.0 TROUBLESHOOTING TABLE

Possible troubles which might occur to the tyre-changer are listed below. The manufacturer disclaims all

responsibility for damages to people, animals or objects due to improper operation by non-unauthorised

personnel. In case of trouble, call Technical Service Department for instructions on how to service and/or

adjust the machine in full safety to avoid any risk of damage to people, animals or objects.

In an emergency and before maintenance on tyre-changer, set the main switch to “0” and lock it in this position.

CONTACT AUTHORIZED TECHNICAL SERVICE

Do not try and service alone.

Problem

Possible cause

Remedy

Pump motor does not work but

wheel holder mandrel motor

works perfectly.

a)

Hydraulic control unit damaged.

a)

Call Technical Service

Dept.

When main switch is turned on,

wheel holder mandrel does not

turn whereas the pump motor

works.

a)

Gearbox change-over switch

damaged.

a)

Call Technical Service

Dept.

Power drop during wheel holder

mandrel rotation.

a)

Timing belt too loose.

a)

Tension up the belt.

No pressure in the hydraulic sys-

tem.

a)

Pump damaged.

a)

Replace pump.

The mandrel opening pressure

does not go down.

a)

Pressure limiting valve jammed.

a)

Download mandrel

(remove wheel), com-

pletely undo adjusting

handle. Perform many

opening and closing

cycles until jam re-

lease.

The machine does not start.

a)

No electricity supply.

b)

Overload cutouts not set.

c)

Transformer fuse blown.

a)

Connect the electricity supply.

b)

Set the overload cutouts.

c)

Change the fuse.

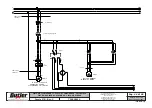

Fluid leaks from union or pipe-

line.

a)

Union not tightened correctly.

b)

Pipeline cracked.

a)

Tighten the union.

b)

Call the after-sales

service.

A control device is remaining on.

a)

The switch has broken.

b)

A solenoid valve has jammed.

a)

Call the after-sales

service.

b)

Call the after-sales

service.

The self-centring chuck cylinder

is losing pressure.

a)

The directional control valve is

leaking.

b)

The gaskets are worn.

a)

Call the after-sales

service.

b)

Call the after-sales

service.

The motor stops during opera-

tion.

a)

Overload cutout tripped.

Open the electrical panel and reset

the overload cutout tripped.

NAV11N - NAV11NT

NAV11EI - NAV11TEI

7505-M001-3_B