INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 19 of 68

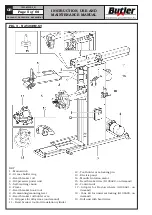

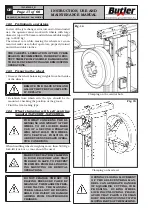

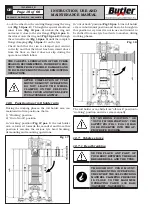

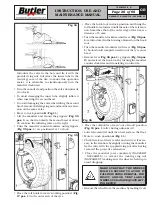

- Lock the wheel on the centring flange using the ring

nut (

Fig. 16 pos. 2

). Through the special small and

inner levers (

Fig. 16 pos. 4

) unlock the ring nut

and move it close to the star flange (

Fig. 16 pos. 1

),

therefore rotate the ring nut (

Fig. 16 pos. 2

) through

the external levers (

Fig. 16 pos. 3

) until the complete

flange clamping (

Fig. 16 pos. 1

) on the tyre;

- Check both that the rim is clamped and centred

correctly, and that the wheel has been raised above

from the floor, so that it does not slip during the

operations which follow.

THE CAREFUL LUBRICATION OF THE TYRES

BEADS IS RECOMMENDED, IN ORDER TO PRO-

TECT THEM FROM POSSIBLE DAMAGES AND

TO FACILITATE MOUNTING AND DEMOUNTING

OPERATIONS.

AFTER COMPLETION OF TYRE

MOUNT/DEMOUNT OPERATIONS

DO NOT LEAVE THE WHEEL

CLAMPED ON THE SELF-CEN-

TRING CHUCK AND NEVER LEAVE

IT UNATTENDED ANYWAY.

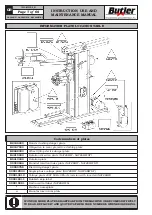

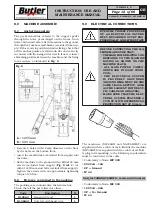

12.6 Functioning of roll holder arm

During the working phases, the roll holder arm can

maintain two firm positions, that is:

1) “Working” position;

2) “Out of work” position.

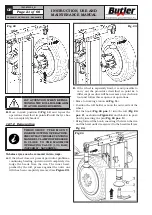

In “working” position (

Fig. 17 pos. 1

) the tool holder

arm is lowered towards the mandrel and from this

position it executes the various tyre bead breaking,

demounting and mounting operations.

Fig. 17

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST

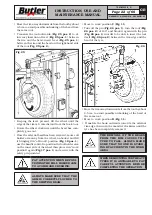

In “out of work” position (

Fig. 18 pos. 1

) the roll holder

arm is in horizontal position and has to be brought in

this position every time it is not in use and in order to

be shifted from one tyre bead side to another, during

working phases.

Fig. 18

The roll holder arm, shifts from “off-work” position to

“working” position and vice versa manually.

IN “WORKING POSITION” OR

“OUT OF WORK POSITION”, THE

SAFETY PIN (FIG. 1 POS. 12) HAS

TO BE INSERTED INTO THE AP-

PROPRIATE HOUSING.

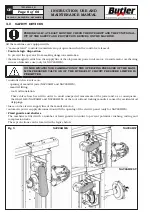

12.7 Tubeless tyres

12.7.1 Bead breaking

NEVER PLACE ANY PART OF

YOUR BODY BETWEEN THE BEAD

BREAKER ROLL AND THE TYRE.

THROUGHOUT TYRE MOUNT-

ING/DEMOUNTING OPERATIONS,

CHECK THAT THE SELF-CENTRING

MANDREL CLAMPING PRESSURE

IS CLOSE TO THE MAXIMUM

OPERATING VALUE (130 BAR)

(NAV26HW - NAV26HW.S).