INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 26 of 68

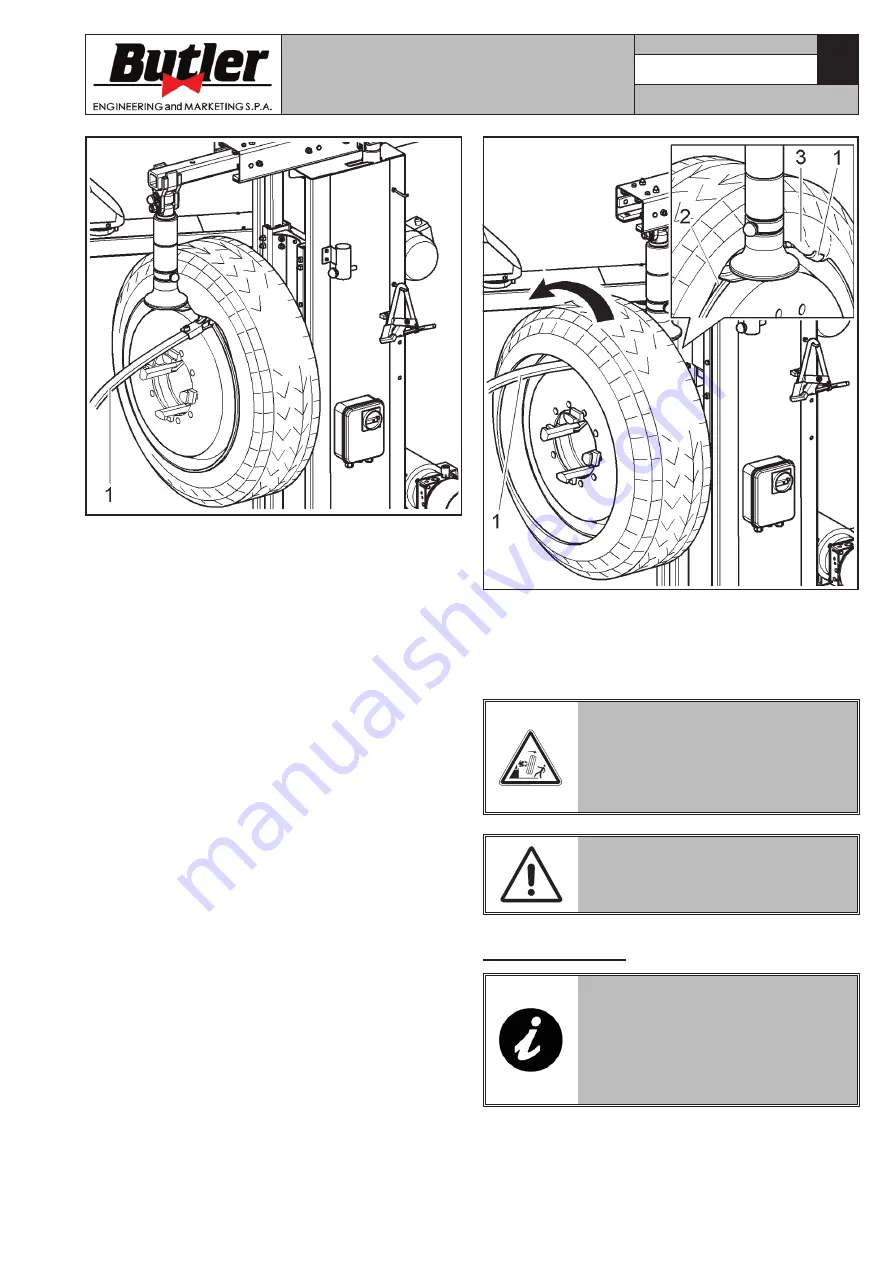

Fig. 31

• Keeping the lever pressed, lift the wheel until the

edge of the rim is approximately 5 mm distant from

the hook tool.

• Turn the wheel clockwise keeping lever pressed until

the bead has gone completely out.

• Move away the roll holder arm in “off-work” position

(

Fig. 18 pos. 1

); lower the mandrel until the tyre

rests on the floor; exert a certain pressure on it; this

will create enough space to extract the inner tube.

• Extract the inner tube and lift the wheel.

• Move to work position

C

(

Fig. 11

).

• Unhook the roll holder arm and place it in “out of

work” (

Fig. 18 pos. 1

); use the handle control to

position the roll holder arm on the inner side of the

wheel; place it in “work position” (

Fig. 17 pos. 1

)

and secure with the safety pin provided (

Fig. 1 2

and

3 pos. 12

).

• Remount the hook tool with 180° rotation, according

to the descriptions in the relevant paragraph, in order

to insert the hook between the rim edge and the tyre

bead; the operation must be carried out during the

mandrel rotation.

• Move the rim away downwards from the tool by about

4-5 cm to avoid possible unhooking of the bead of

the same tool.

• Move to work position

A

(

Fig. 11

).

• Translate the hook tool outwards until the reference

notch is 3 cm inside the rim.

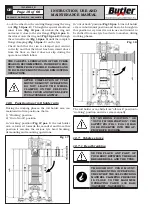

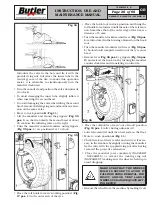

• Insert lever (

Fig. 32 pos. 1

) between the rim (

Fig.

32 pos. 2

) and the bead (

Fig. 32 pos. 3

) on the left-

hand side of the tool.

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST

Fig. 32

• Keeping the lever pressed, lift the wheel until the edge

of the rim is approximately 5 mm distant from the

hook tool then turn the mandrel counterclockwise

keeping the lever (

Fig. 32 pos. 1

) pressed until the

tyre has been completely dislodged from the rim.

THE REMOVAL OF THE BEADS

FROM THE RIM CAUSES THE

TYRE TO FALL. ALWAYS MAKE

SURE THAT NO ONE IS STAND-

ING BY ACCIDENT IN THE WORK

AREA.

WHEN DEMOUNTING VERY HEAVY

TYRES IT IS ADVISABLE TO PAY

CAREFUL ATTENTION BEFORE

COMPLETING THE OPERATION.

12.8.3 Mounting

THROUGHOUT TYRE MOUNT-

ING/DEMOUNTING OPERATIONS,

CHECK THAT THE SELF-CENTRING

MANDREL CLAMPING PRESSURE

IS CLOSE TO THE MAXIMUM

OPERATING VALUE (130 BAR)

(NAV26HW - NAV26HW.S).