INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 16 of 68

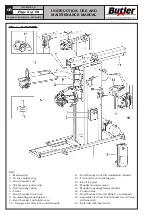

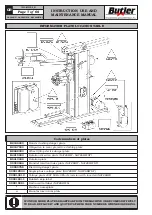

Fig. 13

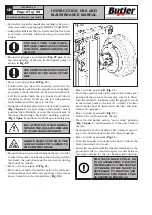

12.0 USING THE MACHINE

12.1 Precaution measures during tyre re-

moval and fitting

Before fitting a tyre, observe the following safety rules:

• always use clean, dry and in good condition rims

and tyres; in particular, if necessary, clean the rims

after all the balancing weights (as well as the adhesive

weights on the inner side) have been removed, and

make sure that:

- neither the bead nor the tread of the tyre are dam-

aged;

- the rim does not produce dents and/or deformation

(especially for alloy rims, dents can cause internal

micro-fractures, that pass unobserved at visual

inspection, and can compromise the solidity of the

rim and constitute danger even during inflation);

• adequately lubricate the contact surface of rim and

tyre bead, using specific tyre lubricants only;

• replace the inner tube valve with a new valve, if the

tyre tube has a metal valve, replace the grommet;

• make sure that the tyre is the right size for the rim;

on the contrary, never fit a tyre unless you are sure

it is the right size (the rated size of the rim and tyre

is usually printed directly on each of them);

• do not use compressed air or water jets to clean the

wheels on the machine.

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST

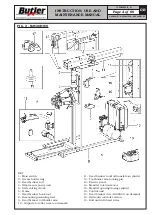

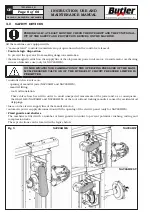

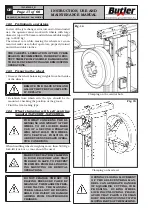

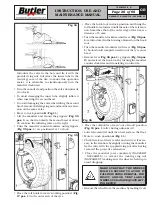

11.2 Control device (NAV26HW.S)

The control unit (handle control), thanks to special

belts, can be fixed to the operator’s body, so that it

follows him and stays within reach during all the pro-

duction phases.

It is advisable for the operator to place himself in a

zone free from obstacles in order to have a clear and

complete vision of the working area.

MAKE SURE THERE ARE NO PER-

SONS OR OBJECTS HIDDEN TO

THE OPERATOR VISUAL FIELD

BY THE WHEEL SIDE PLAY (ESPE-

CIALLY IN CASE OF WHEELS WITH

LARGE DIMENSIONS).

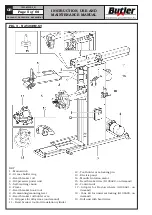

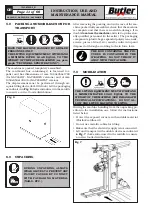

The flashing green led “

A

”, indicates the machine

stand-by position. When any control is operated, the

machine is started and it is ready for operation. Dur-

ing functioning, the green led “

A

” is turned on with a

fixed light.

The simultaneously turned on and flashing led “

B

”

and led “

A

” indicate that the manipulator batteries are

exhausted: in order to carry on the functioning, they

must be charged.

IN ORDER TO ACTIVATE THE COM-

MUNICATION BETWEEN HANDLE

CONTROL AND MACHINE, ON MA-

CHINE SWITCHING AND AFTER

EACH POSITIONING IN STAND-BY

MODE, IT'S NECESSARY TO OPER-

ATE ANY JOYSTICK (LEVER “H”

OR LEVER “I”) FOR 5 SECONDS

AT LEAST.

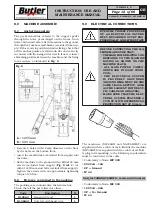

When the red led“

B

” lights up indicates that there is

a fault in the bluetooth connection with the machine.

“Push-button

C

” has one “hands-on” operating posi-

tion, and when pressed, it opens the self-centring

chuck.

“Push-button

D

” has one “hands-on” operating posi-

tion, and when pressed, it closes the self-centring

chuck.

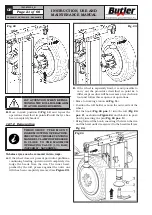

“Lever

E

” has four “hands-on” positions:

- Lever to the right or left: it starts the travel of the

bead breaking roll/tool to the right or left respectively

(from “B” working position,

Fig. 11

).

- Upwards or downwards lever: it respectively lifts or

lowers the mandrel.

“Lever

F

” has two “hands-on” positions:

- Lever to the right or left, operates the clockwise or

counterclosckwise rotation of the mandrel (from

working position “A”

Fig. 11

).

When any control is operated, the machine is started

again, ready for operation: led “

A

” flashes.

THE HANDLE CONTROL MUST

NOT BE PLACED WHERE WATER

STAGNATES.