INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 17 of 68

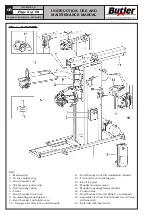

Fig. 14

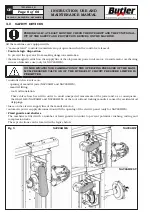

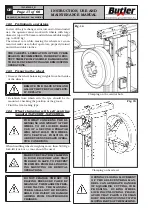

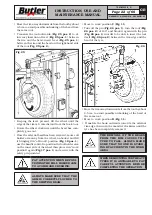

Clamping on the central hole

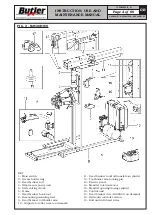

Fig. 15

Clamping on bead seat

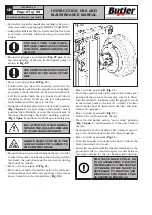

OPENING/CLOSING MOVEMENT

OF THE SELF-CENTRING MAN-

DREL CAN GENERATE DANGER

OF SQUASHING, CUTTING, COM-

PRESSING. DURING WHEEL

LOCKING/UNLOCKING PHASE,

AVOID THAT PARTS OF HUMAN

BODY COME INTO CONTACT WITH

MOVING PARTS OF THE MACHINE.

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST

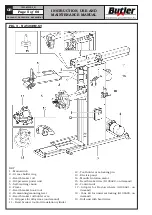

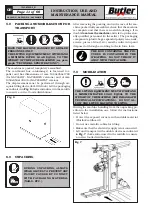

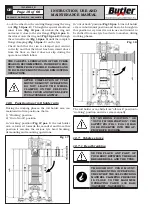

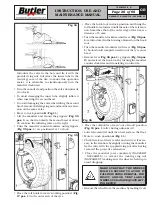

12.2 Preliminary operations

In view of the tyre changer structure and of its intended

use, the operator must work with wheels with large

diameter (up to 2550 mm) and with remarkable weight

(up to 2300 kg).

The utmost care while moving the wheels is recom-

mended: make use of other operators, properly trained

and with suitable clothes.

THE CAREFUL LUBRICATION OF THE TYRES

BEADS IS RECOMMENDED, IN ORDER TO PRO-

TECT THEM FROM POSSIBLE DAMAGES AND

TO FACILITATE MOUNTING AND DEMOUNTING

OPERATIONS.

12.3 Preparing the wheel

• Remove the wheel balancing weights from both sides

of the wheel.

REMOVE THE VALVE STEM AND

ALLOW THE TYRE TO COMPLETE-

LY DEFLATE.

• Establish from which side the tyre should be de-

mounted, checking the position of the groove.

• Find the rim locking type.

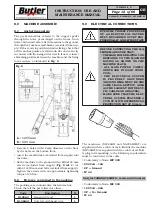

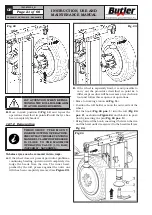

12.4 Wheel clamping with self-centring

mandrel (NAV26HW - NAV26HW.S)

FOR WHAT CONCERNS THE DI-

MENSIONS AND WEIGHT OF THE

WHEEL TO BE LOCKED, MAKE

USE OF A SECOND OPERATOR

WHO MUST HOLD THE WHEEL

INTO VERTICAL POSITION, IN

ORDER TO ENSURE SAFE OPERA-

TIVE CONDITIONS.

When handling wheels weighing more than 500 Kg a

fork-lift truck or a crane should be used.

MAKE SURE THAT RIM CLAMPING

IS DONE PROPERLY AND THAT

THE GRIP IS SAFE, TO PREVENT

THE WHEEL FROM FALLING DUR-

ING MOUNTING OR REMOVAL

OPERATIONS.

DO NOT CHANGE THE SET OP-

ERATING PRESSURE VALUE BY

MEANS OF THE MAXIMUM PRES-

SURE VALVES. THE MANUFAC-

TURER SHALL NOT BE RESPON-

SIBLE FOR INJURY OR DAMAGE

ARISING FROM UNAUTHORISED

CHANGES.