INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 18 of 68

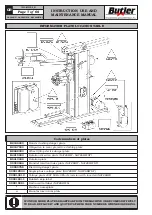

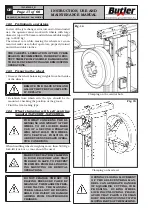

All wheels must be clamped from the inside.

Clamping on the central flange is always safest.

NOTE: for wheels with grooved rims secure the

wheel so the groove is facing outward compared to

the mandrel.

If it is not possible to clamp the rim in the hole of the

disc, clamp on the bead seat close to the disc.

TO SECURE WHEELS WITH ALLOY

RIMS ADDITIONAL PROTECTIVE

JAWS ARE AVAILABLE. THEY AL-

LOW YOU TO WORK ON THE RIMS

WITHOUT DAMAGING THEM. THE

PROTECTIVE JAWS ARE FITTED

ONTO THE MANDREL’S NORMAL

JAWS BY MEANS OF A BAYONET

CONNECTION.

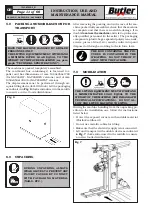

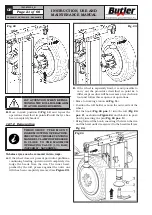

To clamp the wheel proceed as follows:

- Place the wheel in vertical position not far from the

mandrel;

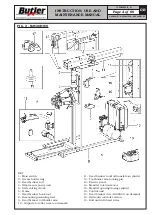

- Use the lever (

Fig. 12 pos. C

) or (

Fig. 13 pos. E

) to

position the coaxial mandrel with the wheel centre,

in order to make the jaws edges skim the wheel edge;

- Adjust the opening of the self-centring mandrel

through the corresponding control (

Fig. 12 pos. A

)

or (

Fig. 13 pos. C

) according to the type of rim to

be locked;

- Operate the control (

Fig. 12 pos. A

) or (

Fig. 13 pos.

C

) until the wheel is completely clamped.

- Check both that the rim is clamped and centred

correctly, and that the wheel has been raised above

from the floor, so that it does not slip during the

operations which follow.

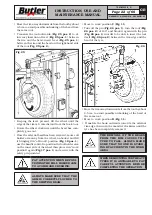

KEEP ON OPERATING RIM CLAMP-

ING CONTROL, UNTIL REACHING

THE MAXIMUM OPERATING PRES-

SURE (130 BAR).

THE CAREFUL LUBRICATION OF THE TYRES

BEADS IS RECOMMENDED, IN ORDER TO PRO-

TECT THEM FROM POSSIBLE DAMAGES AND

TO FACILITATE MOUNTING AND DEMOUNTING

OPERATIONS.

AFTER COMPLETION OF TYRE

MOUNT/DEMOUNT OPERATIONS

DO NOT LEAVE THE WHEEL

CLAMPED ON THE SELF-CEN-

TRING CHUCK AND NEVER LEAVE

IT UNATTENDED ANYWAY.

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST

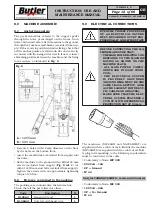

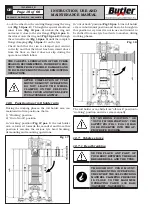

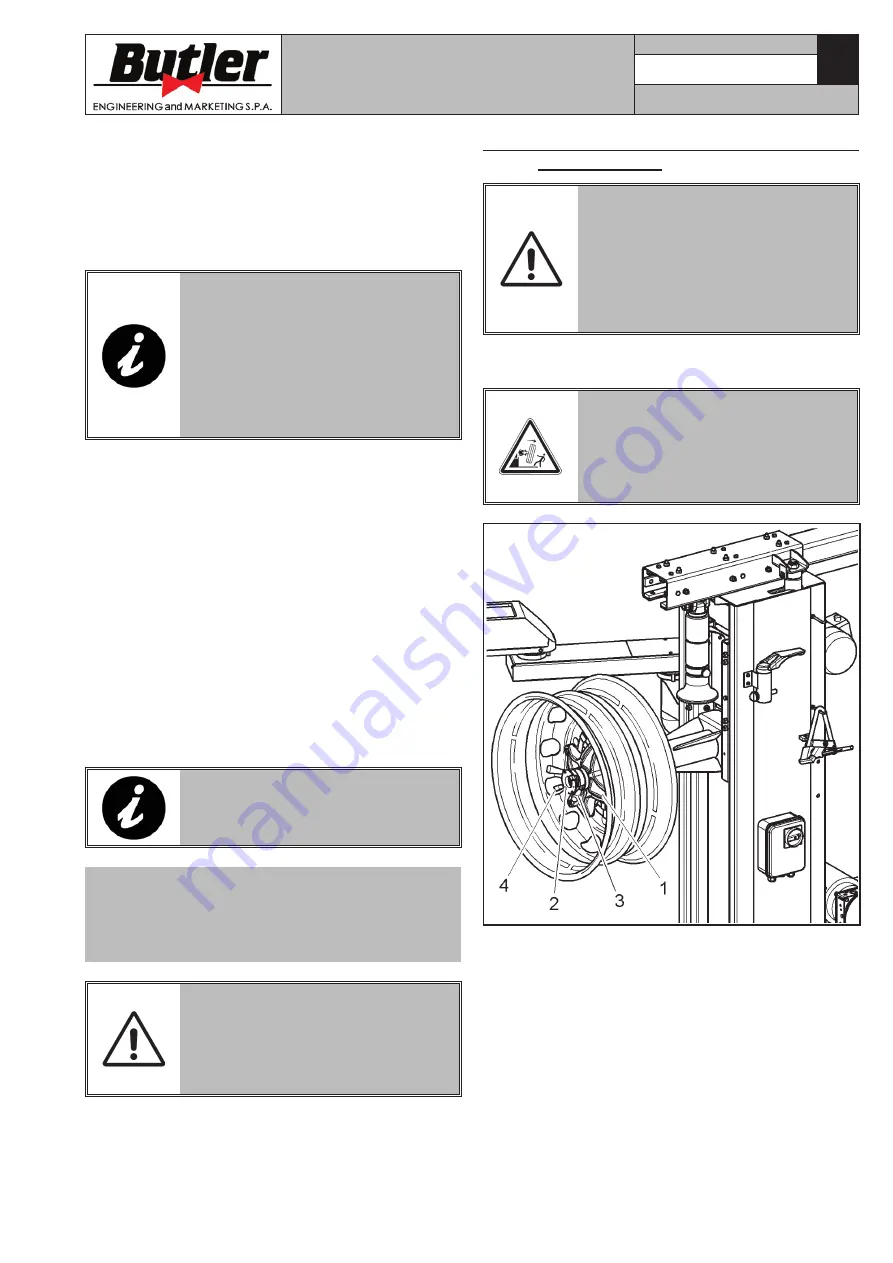

12.5 Wheel clamping with locking ring nut

(NAV26HW.ST)

FOR WHAT CONCERNS THE DI-

MENSIONS AND WEIGHT OF THE

WHEEL TO BE LOCKED, MAKE

USE OF A SECOND OPERATOR

WHO MUST HOLD THE WHEEL

INTO VERTICAL POSITION, IN

ORDER TO ENSURE SAFE OPERA-

TIVE CONDITIONS.

When handling wheels weighing more than 500 Kg a

fork-lift truck or a crane should be used.

MAKE SURE THAT RIM CLAMPING

IS DONE PROPERLY AND THAT

THE GRIP IS SAFE, TO PREVENT

THE WHEEL FROM FALLING DUR-

ING MOUNTING OR REMOVAL

OPERATIONS.

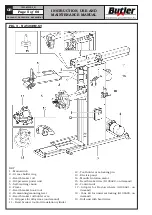

Fig. 16

To clamp the wheel proceed as follows:

- Place the wheel in vertical position not far from the

mandrel;

Use the lever (

Fig. 12 pos. C

) to position the coaxial

mandrel with the wheel centre, so that the threaded

pin is placed at the same height of the central hole

of the rim;

- Insert the rim on the threaded pin (and the well

placed outwards);

- Lock the rim on the mandrel by using the star flange

(

Fig. 16 pos. 1

) and make sure that drive pin goes

into the right hole for the tyre;